Device and method for recovering epoxypropane from epoxypropane-carbon dioxide copolymer washing liquid

A technology of propylene oxide and carbon dioxide, applied in the direction of organic chemistry, etc., can solve the problems of high cooling energy consumption and high energy consumption, and achieve the effects of low operating cost, low energy consumption, and avoiding side reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

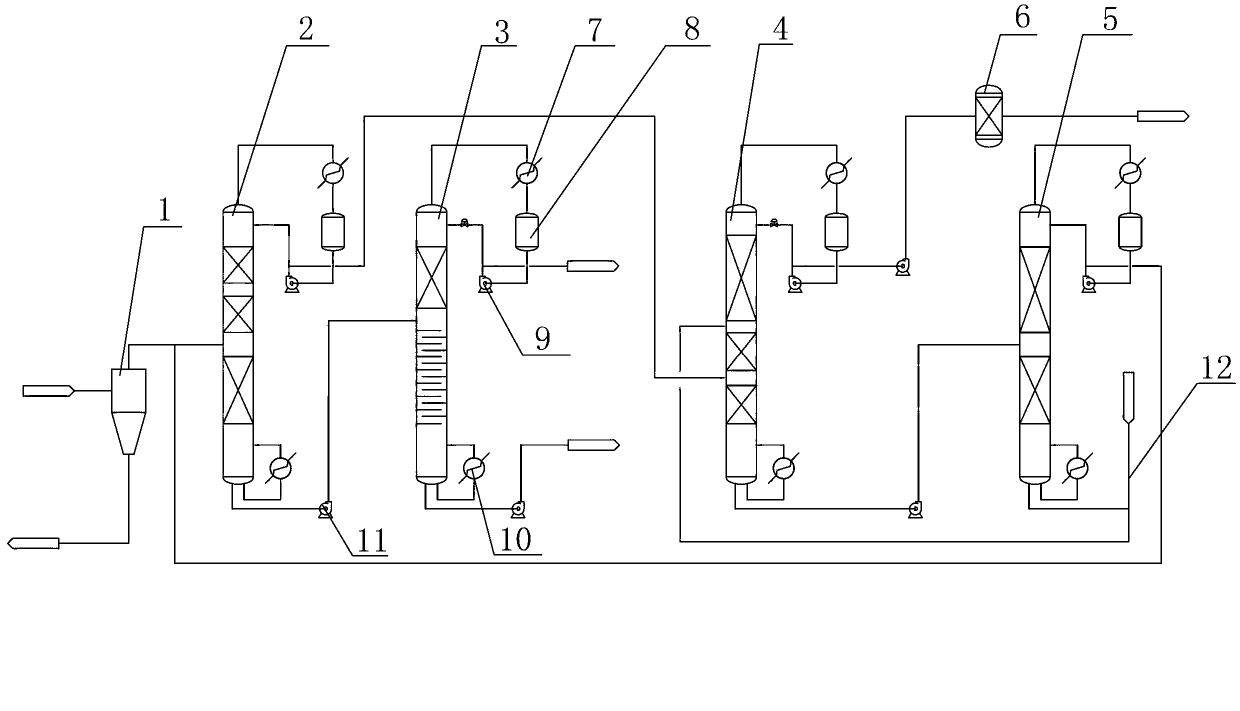

[0026] A kind of equipment of the present invention reclaims propylene oxide from propylene oxide-carbon dioxide copolymer washing liquid, as figure 1 Shown, comprise liquid-solid separator 1, crude propylene oxide rectification tower 2, methanol recovery tower 3, extractive rectification tower 4, extraction water recovery tower 5 and molecular sieve adsorption tower 6, liquid-solid separator 1 and crude epoxy The middle inlet of the propane rectification tower 2 is connected, the top outlet of the crude propylene oxide rectification tower 2 is connected with the lower inlet of the extractive distillation tower 4, and the bottom outlet of the crude propylene oxide rectification tower 2 is connected with the methanol recovery tower 3 The inlet connection of the extractive distillation tower 4 is connected with the molecular sieve adsorption tower 6, the outlet at the bottom of the extractive distillation tower 4 is connected with the middle part inlet of the extraction water rec...

Embodiment 2

[0030] A method of reclaiming propylene oxide from the propylene oxide-carbon dioxide copolymer washing liquid of the present invention, such as figure 1 As shown, the specific steps are as follows:

[0031] (1) Send the propylene oxide-carbon dioxide copolymer washing liquid into the liquid-solid separator 1 to remove most of the catalyst particles to obtain clear liquid;

[0032] (2) Send the clear liquid into the crude propylene oxide rectification tower 2, control the tower top temperature to 40°C, and the tower top pressure to 103kpa, and separate through the crude propylene oxide rectification tower 2, the purity obtained at the top of the tower is 96.5wt%. The thick propylene oxide, obtains the mixed solution containing methanol at the bottom of the tower;

[0033] (3) Send the crude propylene oxide into the extractive distillation tower 3, control the temperature at the top of the tower to 39°C, and the pressure at the top of the tower to 103kpa, separate through the ...

Embodiment 3

[0040] Same as Example 2, the difference is that in step (2), the temperature at the top of the tower is controlled to be 35°C, the pressure at the top of the tower is 101kpa, and the crude propylene oxide rectifying tower 2 is separated, and the crude epoxy resin with a purity of 95wt% is obtained at the top of the tower. Propane; In the step (3), the temperature at the top of the tower is controlled to be 35° C., and the pressure at the top of the tower is 101 kpa, separated by the extractive distillation tower 3, and the propylene oxide with a purity higher than 99.95wt% is obtained at the top of the tower; in the step (4), the control tower The top temperature is 60°C and the top pressure is 101kpa. After separation by the methanol recovery tower 3, methanol with a purity of more than 99% is obtained at the top of the tower; in step (6), the top temperature is controlled at 40°C and the top pressure is 101kpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com