Non-toxic releasing anti-fouling paint and preparation method thereof

A technology of antifouling paint and component A, which is applied in the direction of antifouling/underwater paint, paint containing biocide, and a device for coating liquid on the surface, which can solve the problem of marine environment damage and low release of biocide , poor effect and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

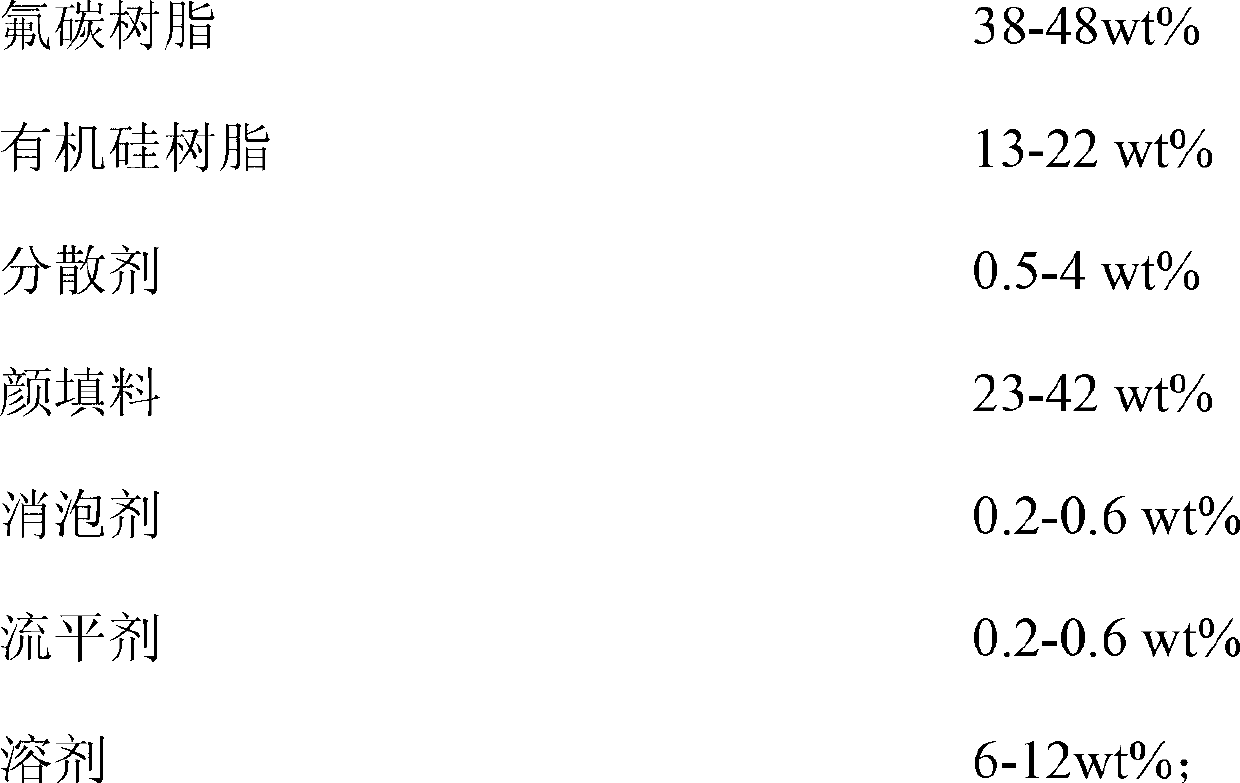

[0060] Table 1 is each component and content of the antifouling paint described in embodiment 1-3:

[0061] Each component and content of the antifouling paint described in table 1 embodiment 1-3

[0062]

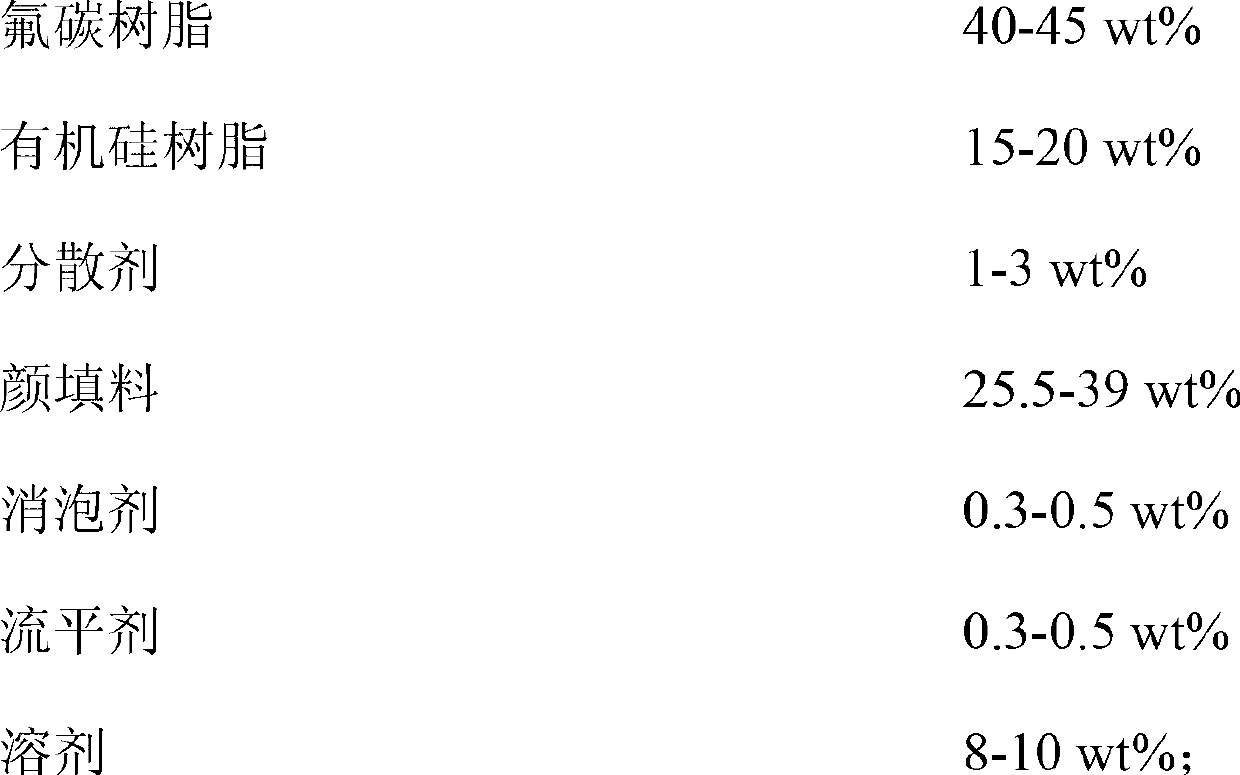

[0063] Table 1 is each component and content of the antifouling paint described in embodiment 4-6:

[0064] Each component and content of the antifouling paint described in table 1 embodiment 4-6

[0065]

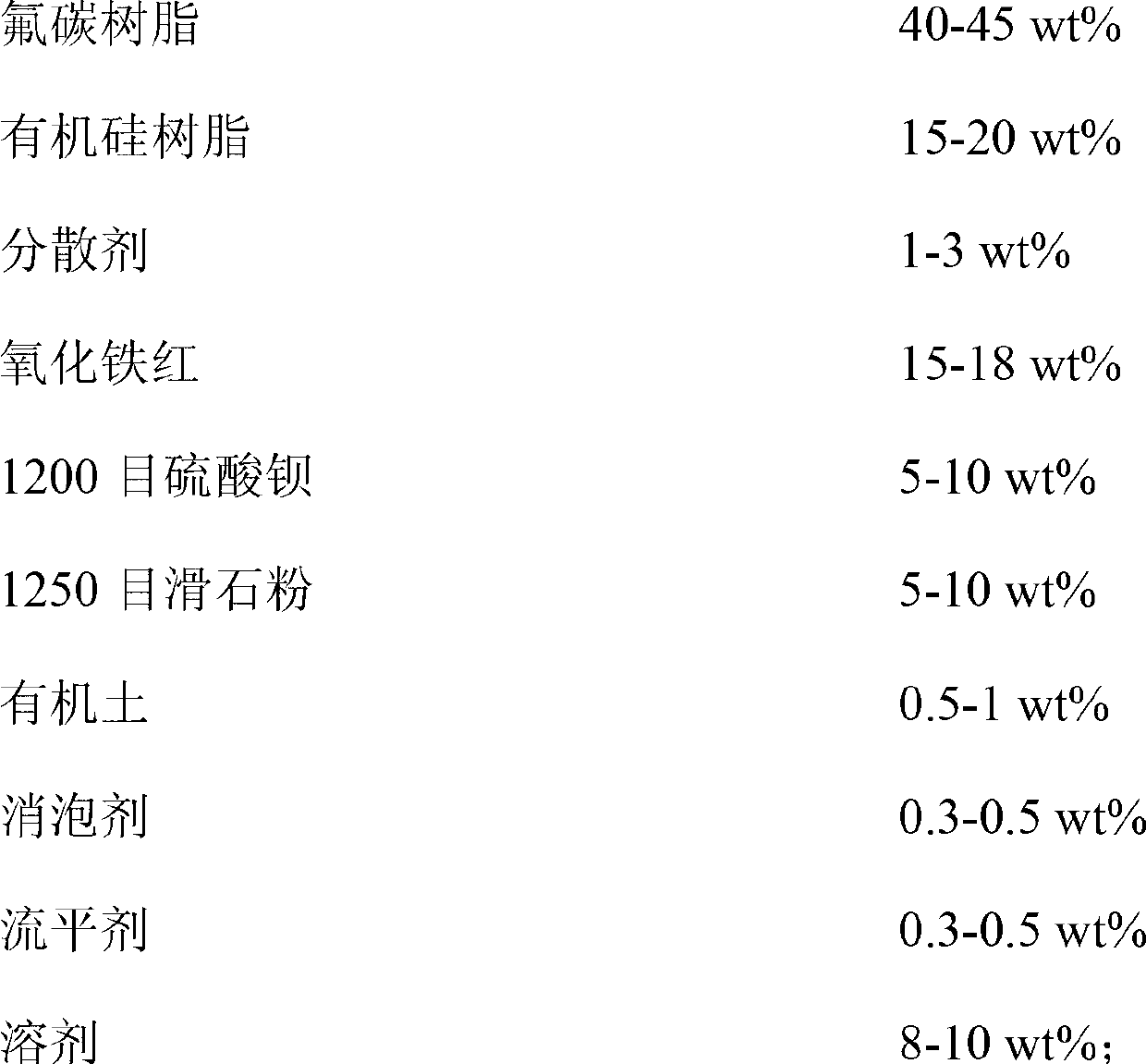

[0066]

[0067] Iron oxide red in Examples 1-5 can be equivalently replaced by iron oxide yellow or iron oxide black; the mesh number of the talc powder is 1000-1500 mesh, and the mesh number of the barium sulfate is 1000-1400 mesh.

[0068] The pigments and fillers can be any one or at least two of iron oxide red, iron oxide black, iron oxide yellow, talc powder, rutile titanium dioxide, barite powder, zinc oxide, carbon black, organic soil, and barium sulfate The combination.

Embodiment 1-6

[0069] The preparation method of embodiment 1-6 is:

[0070] (1) Put the formulated amount of fluorocarbon resin, silicone resin and solvent into the dispersion kettle, and stir evenly;

[0071] (2) Add the formulated amount of pigments and fillers to the dispersion tank and stir for 20-50 minutes, such as 23 minutes, 29 minutes, 35 minutes, 38 minutes, 42 minutes, 45 minutes, 48 minutes, etc., preferably 30 minutes;

[0072] (3) Grind the raw materials in the dispersion tank to ≤60 μm, such as 58 μm, 55 μm, 51 μm, 48 μm, 46 μm, 30 μm, etc., and finally adjust the viscosity to pass with a solvent;

[0073] Preferably, the grinding is performed in a horizontal sand mill.

[0074] The construction method of the non-toxic material release type antifouling paint described in embodiment 1-6 is:

[0075] Mix the component A and curing agent described in Examples 1-6 of the present invention according to the ratio of 100: (2-8) by mass percentage, for example, the mixing ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com