Small wear-resistant bush for blast-furnace tuyere and manufacture method thereof

A manufacturing method and tuyere technology, applied in the direction of the tuyere, can solve the problems of not being able to change the area of the small set of tuyere in stock, limited wear resistance, and easy fatigue and stratification during use, so as to achieve good resistance to rapid cooling and rapid heating, prolong service life, The effect of avoiding wind loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

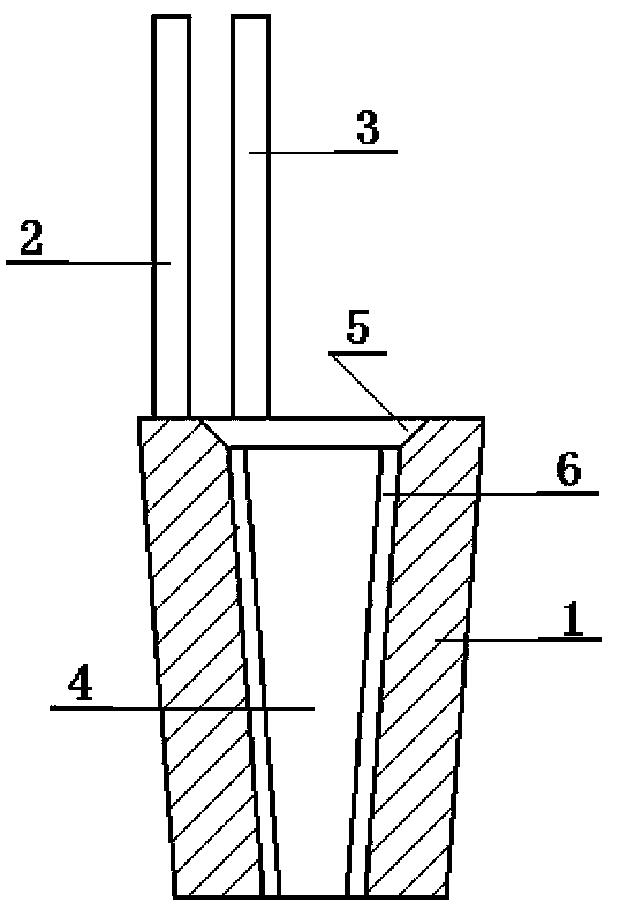

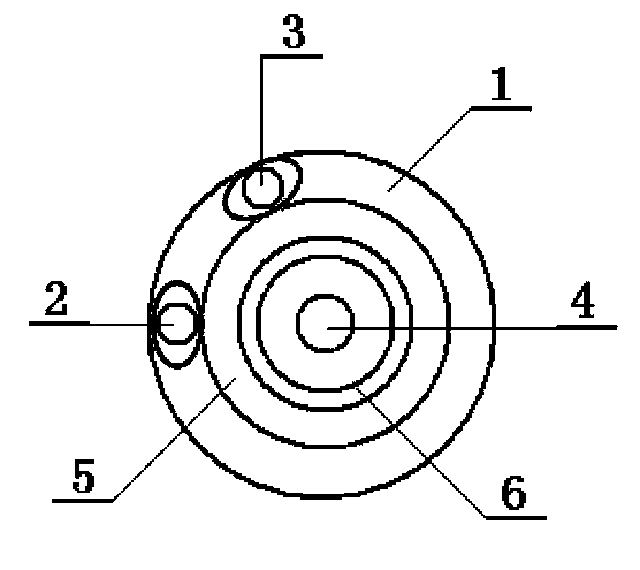

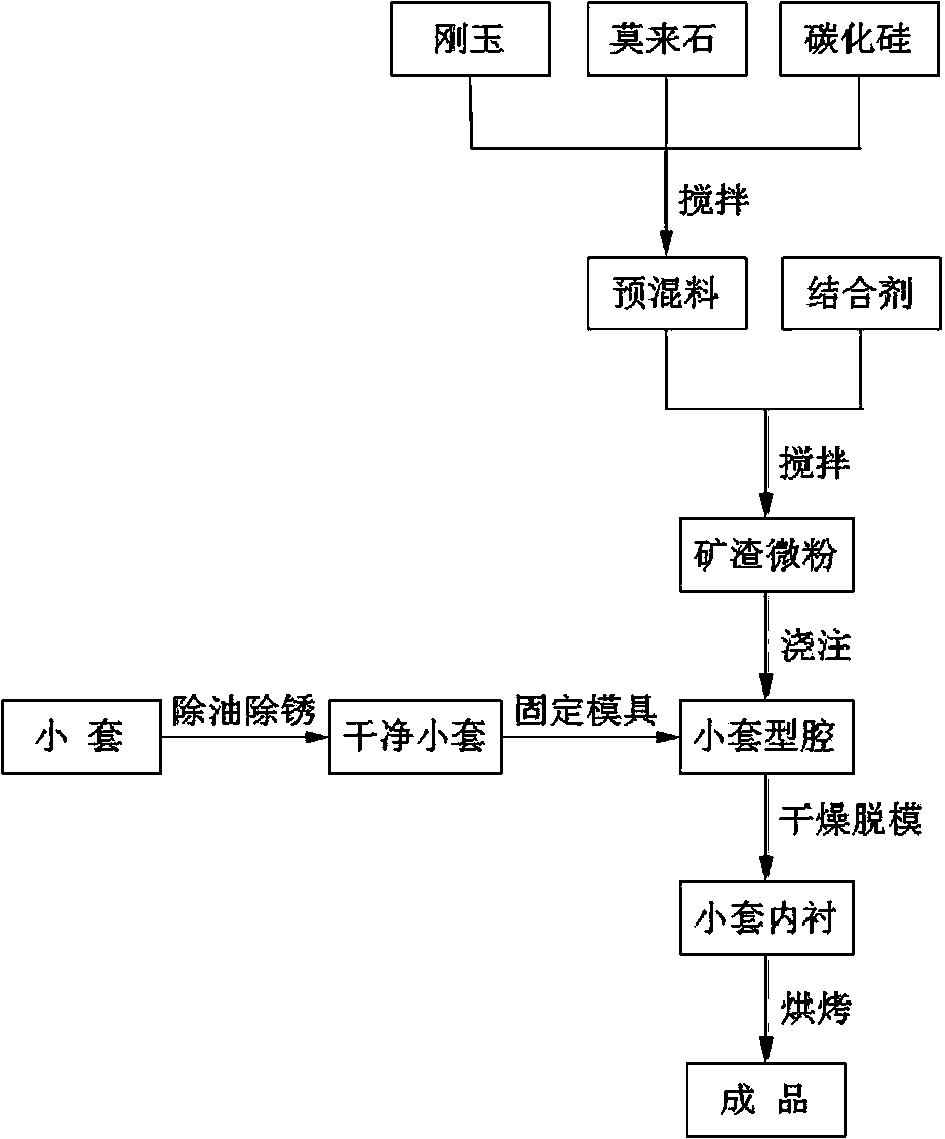

Embodiment 1

[0038] Put the inner wall of the new small sleeve that needs to be lined upright after derusting and grease removal, and then place it vertically on the pre-made platform. According to the size of the inner hole of the prefabricated wear-resistant lining, select a suitable inner mold to be coaxial with the inner wall of the small sleeve Install and fix; pour 60kg of corundum, 15kg of mullite and 25kg of silicon carbide in total 100kg into the forced mixer and stir for 3 minutes, then add 7.5kg of aluminum sol and 7.5kg of silica sol, and continue stirring for 5 minutes to obtain Castable: pour the mixed castable between the small sleeve and the inner mold to fill up the space; take off the inner mold after the small sleeve poured with wear-resistant lining is naturally air-dried for 4 hours; put the wear-resistant lining Together with the small sleeve, use a gas fire to raise the temperature at a rate of 1°C / min, so that the surface temperature of the wear-resistant lining rise...

Embodiment 2

[0040] The inner wall of the new small sleeve that needs to be lined is derusted and grease-removed. According to the size of the inner hole of the prefabricated wear-resistant lining, a suitable mold and small sleeve are installed and fixed to form a lining cavity; corundum 60kg, Molai 8kg of stone and 12kg of silicon carbide totaling 80kg were poured into the vertical mixer and stirred for 2 minutes, then 18kg of silica sol was added, and the castable was obtained after stirring for 3 minutes; pour the stirred castable between the small sleeve and the inner mold It is enough to fill the space with vibration; the small sleeve cast with wear-resistant lining is dried at a low temperature of 60°C for 2 hours, and then the mold is removed; The surface temperature of the wear-resistant lining rises to 250°C, and then the small sleeve is connected with cooling water and kept warm for 4 hours. Under the condition of water cooling, the temperature is raised at a rate of 2°C / min, so t...

Embodiment 3

[0042]The inner wall of the new small sleeve that needs to be lined is derusted and grease-removed. According to the size of the inner hole of the prefabricated wear-resistant lining, a suitable mold and small sleeve are installed and fixed to form a lining cavity; corundum 84kg, Molai 16kg of stone and 20kg of silicon carbide totaling 120kg were poured into the twin-shaft mixer and stirred for 5 minutes, then 16kg of aluminum sol was added, and the castable was obtained after stirring for 10 minutes; pour the stirred castable between the small sleeve and the inner mold Just fill the space with vibration; take off the mold after 8 hours of natural air-drying for the small sleeve poured with wear-resistant lining; heat the wear-resistant lining together with the small sleeve at a rate of 1°C / min in an oven to make the wear-resistant The surface temperature of the inner lining rises to 350°C, and then the small sleeve is connected with cooling water and kept warm for 2 hours. Und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com