Feeding method of aluminum scrap and edge cutting material

A feeding method and trimming technology, which is applied in the field of aluminum alloy manufacturing, can solve the problems of ingot performance hazards, product strength, plasticity, impact toughness and fracture toughness reduction, etc., so as to reduce the output of aluminum slag and reduce metal burning loss , the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 A kind of feeding method of aluminum shavings and trimmings

[0023] Include the following steps:

[0024] (1) When batching, each furnace is equipped with a bucket of aluminum chips and trimmings (8~10t), which are placed separately in front of the furnace. Put other prepared materials into the smelting furnace, ignite and heat up to melt.

[0025] (2) Wait until the molten aluminum is completely melted, and the temperature of the molten aluminum reaches 745°C.

[0026] (3) Remove the furnace cover, open a small gap in the barrel, and bake the aluminum scraps and trimmings at the bottom for 5 minutes by the hot air in the furnace to prevent the possibility of moisture.

[0027] (4) Slowly add a bucket of aluminum chips and trimmings into the furnace. Turn on the stirrer to stir, and use the heat of fusion of aluminum water and the latent heat of the furnace to melt the aluminum chips and trimmings.

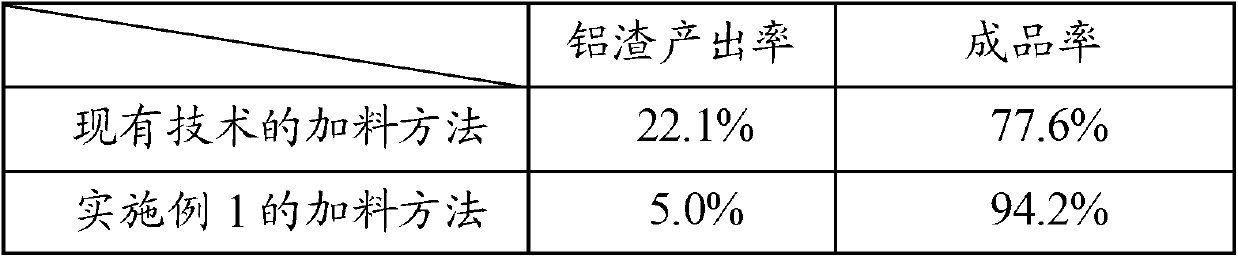

[0028] Adopt the charging method of this embodiment ...

Embodiment 2

[0035] Embodiment 2 A kind of feeding method of aluminum shavings and trimmings

[0036] Include the following steps:

[0037] (1) When batching, each furnace is equipped with a bucket of aluminum chips and trimmings (8~10t), which are placed separately in front of the furnace. Put other prepared materials into the smelting furnace, ignite and heat up to melt.

[0038] (2) Wait until the molten aluminum is completely melted, and the temperature of the molten aluminum reaches 755°C.

[0039] (3) Remove the furnace cover, open a small gap in the barrel, and bake the aluminum chips and trimmings at the bottom for 3 minutes by the hot air in the furnace to prevent the possibility of moisture.

[0040] (4) Slowly add a bucket of aluminum chips and trimmings into the furnace. Turn on the stirrer to stir, and use the heat of fusion of aluminum water and the latent heat of the furnace to melt the aluminum chips and trimmings.

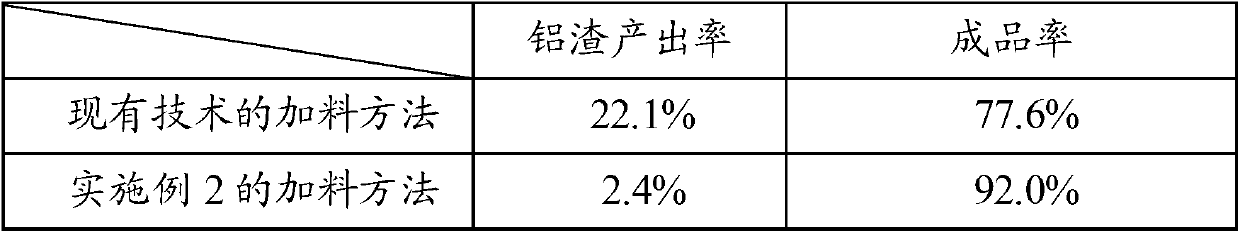

[0041] The feeding method of this embodiment is used ...

Embodiment 3

[0048] Embodiment 3 A kind of feeding method of aluminum shavings and trimmings

[0049] Include the following steps:

[0050] (1) When batching, each furnace is equipped with a bucket of aluminum chips and trimmings (8~10t), which are placed separately in front of the furnace. Put other prepared materials into the smelting furnace, ignite and heat up to melt.

[0051] (2) Wait until the molten aluminum is completely melted, and the temperature of the molten aluminum reaches 750°C.

[0052] (3) Remove the furnace cover, open a small gap in the barrel, and bake the aluminum scraps and trimmings at the bottom for 5 minutes by the hot air in the furnace to prevent the possibility of moisture.

[0053] (4) Slowly add a bucket of aluminum chips and trimmings into the furnace. Turn on the stirrer to stir, and use the heat of fusion of aluminum water and the latent heat of the furnace to melt the aluminum chips and trimmings.

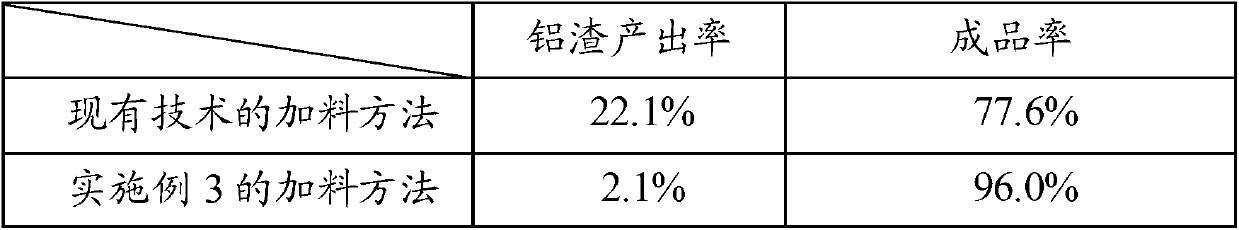

[0054] The feeding method of this embodiment is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com