Active optical fiber structure for gaining application and achieving method thereof

An optical fiber structure and optical fiber preform technology, which can be used in multi-layer core/cladding optical fibers, graded index core/cladding optical fibers, applications, etc., and can solve the problem of fiber strength and bending resistance. Improve the production yield and other problems, to achieve the effect of low splicing loss, reducing splicing loss, and improving refractive index difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

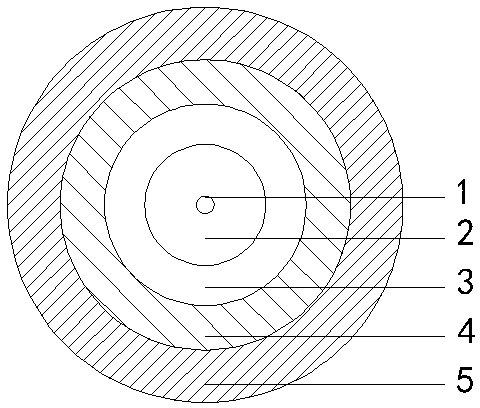

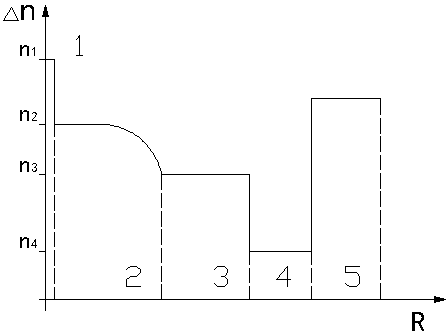

[0026] The graded-index cladding active optical fiber shown in Example 1 has a core diameter of 11 μm, a core numerical aperture (NA) of 0.07, a graded-index inner cladding diameter of 75 μm, a silica cladding diameter of 125 μm, and a circular silica cladding shape. , the optical fiber is coated with an outer diameter of 245 μm. The measured absorption coefficient of the fiber at 915nm is 1.8dB / m, and the slope efficiency of the fiber laser made from a 7m fiber is 75.6%.

[0027] The double-clad active optical fiber preform of Example 1 is manufactured by using MCVD or PCVD technology. When making an optical fiber preform, firstly, a graded-refractive-index inner cladding 2 with a higher refractive index than the quartz outer cladding 3 (deposition tube) is deposited in the deposition tube. The deposition process is SiCl 4Flow remains constant at 600sccm, GeCl 4 The initial flow rate is 30sccm, and 40 layers are deposited incrementally per layer at a flow rate of 2sccm, and...

Embodiment 2

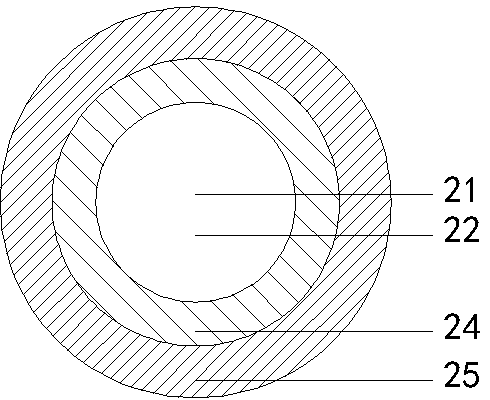

[0029] The graded-index cladding active fiber of Example 2 has a core diameter of 11 μm, a core numerical aperture (NA) of 0.07, a diameter of graded-index silica cladding of 125 μm, a circular cladding shape, and an optical fiber coating outer diameter of 245 μm. The measured absorption coefficient of the fiber at 915nm is 1.9dB / m, and the slope efficiency of the fiber laser made from a 7m fiber is 77%.

[0030] Embodiment 2 is manufactured by PCVD process. When the optical fiber preform is made, a graded-refractive-index quartz cladding 22 with a lower refractive index than the quartz deposition tube is deposited in the deposition tube, and the deposition process is SiCl 4 The flow remains constant at 600sccm, C 2 f 6 The initial flow rate is 100 sccm, and 1000 layers are deposited in each layer at a flow rate of 0.06 sccm, and then 1000 layers are deposited at a flow rate of 0.03 sccm for each layer, and then 500 layers are deposited at a flow rate of 0.01 sccm for each l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com