Super capacitance battery and preparation method thereof

A technology of supercapacitor battery and conductive agent, which is applied in the field of capacitors and can solve the problems of low energy density and low power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

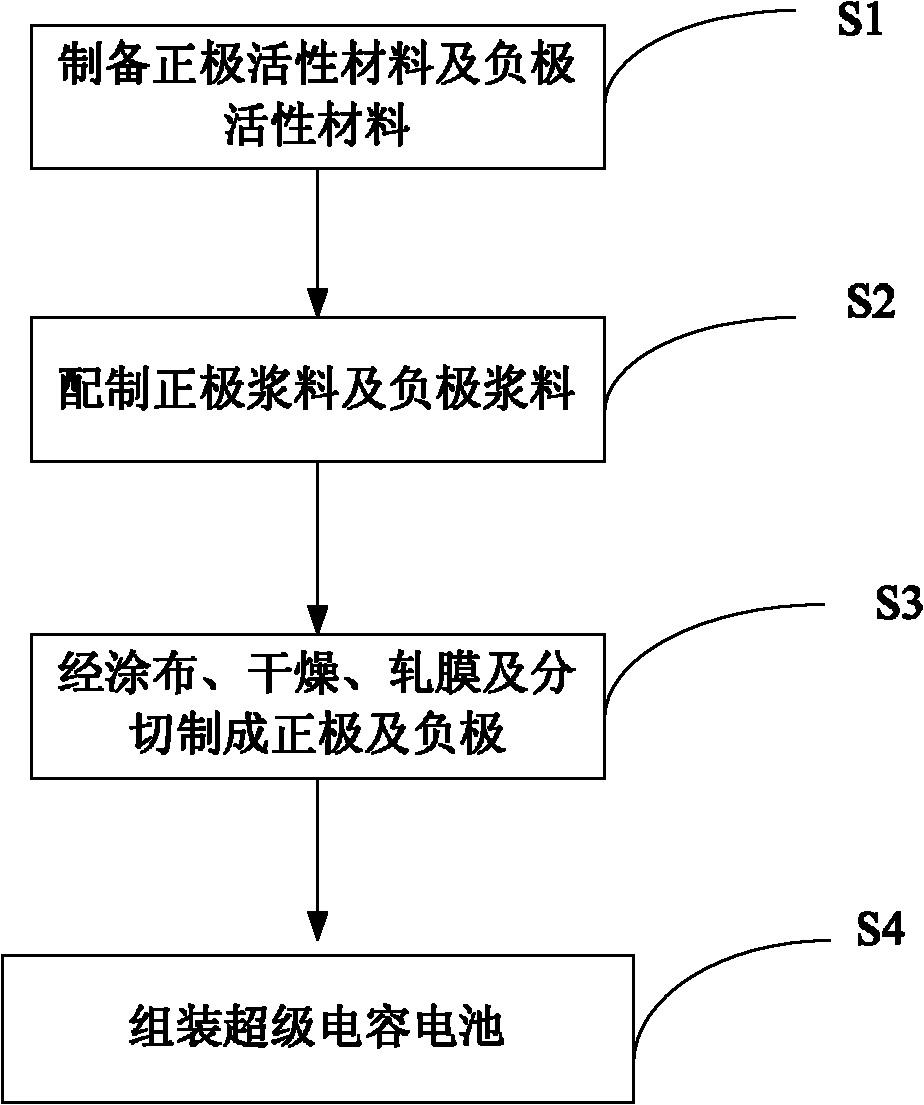

[0030] like figure 1 Shown, the preparation method of above-mentioned super capacitor battery, comprises the steps:

[0031]Step S1, preparing a positive electrode active material by mixing a carbon material and a lithium ion material, the content of the carbon material in the positive electrode active material is greater than or equal to 70% and less than 100%, and the mass ratio is 1-20:80- The 99% silicon mixture is mixed with graphene to prepare the negative electrode active material, and the silicon mixture is composed of simple silicon and silicon dioxide with a mass ratio of 1:19-19:1. In this embodiment, the preparation process of the negative electrode active material also includes the following steps: preparing a mixture of silicon dioxide powder and graphite oxide powder, ball-milling the mixture and placing it in a tube furnace with a reducing atmosphere at 10-100°C. Slowly raise the temperature to 200-1200° C. at a rate of 1-10 hours, heat for 1-10 hours to obtai...

Embodiment 1

[0038] Positive electrode: Mix positive active material activated carbon, binder PVDF and conductive agent acetylene black at a mass ratio of 85:10:5, add solvent NMP to adjust the viscosity of the slurry to 2500 Ns / square meter, and coat it on aluminum foil. Then it is dried and rolled into a film, and cut into positive electrodes.

[0039] Negative electrode: (1) Mix silicon dioxide powder and graphite oxide powder with a mass ratio of 1:10, ball mill and place in a reducing atmosphere (a mixture of hydrogen and argon with a volume percentage of 5:95) tube furnace Slowly raise the temperature to 200°C at a rate of 10°C / min, and then heat it for 1 hour to obtain a powder mixture, and then cool the powder mixture to room temperature with the furnace in a reducing atmosphere to obtain a negative active electrode composed of a silicon mixture and graphene. material, wherein the mass ratio of silicon mixture and graphene is 20:80, and the mass ratio of elemental silicon and silic...

Embodiment 2

[0045] Positive electrode: active carbon and lithium iron phosphate material with a mass ratio of 70:30 are prepared as the positive electrode active material. Mix the positive electrode active material, binder PVDF and conductive agent acetylene black in a mass ratio of 90:5:5, add solvent NMP to adjust the viscosity of the slurry to 1500 Ns / square meter, coat the aluminum foil, then dry and Rolled film, cut into positive electrode.

[0046] Negative electrode: (1) Mix silicon dioxide powder and graphite oxide powder with a mass ratio of 1:10, and place them in a reducing atmosphere (a mixture of hydrogen and argon with a volume percentage of 5:95) after ball milling. Slowly raise the temperature in the furnace to 400°C at a rate of 20°C / min, then heat it for 2 hours to obtain a powder mixture, and then cool the powder mixture to room temperature with the furnace in a reducing atmosphere to obtain a negative electrode composed of a silicon mixture and graphene Active materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy density | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com