Preparation method for side gating graphene field effect transistor

A field-effect transistor and graphene technology, which is applied in semiconductor/solid-state device manufacturing, gaseous chemical plating, coating, etc., can solve the problems of improving the transconductance of field-effect transistors, easily destroying graphene, and expensive SiC wafers. Achieve the effect of improving modulation ability and avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

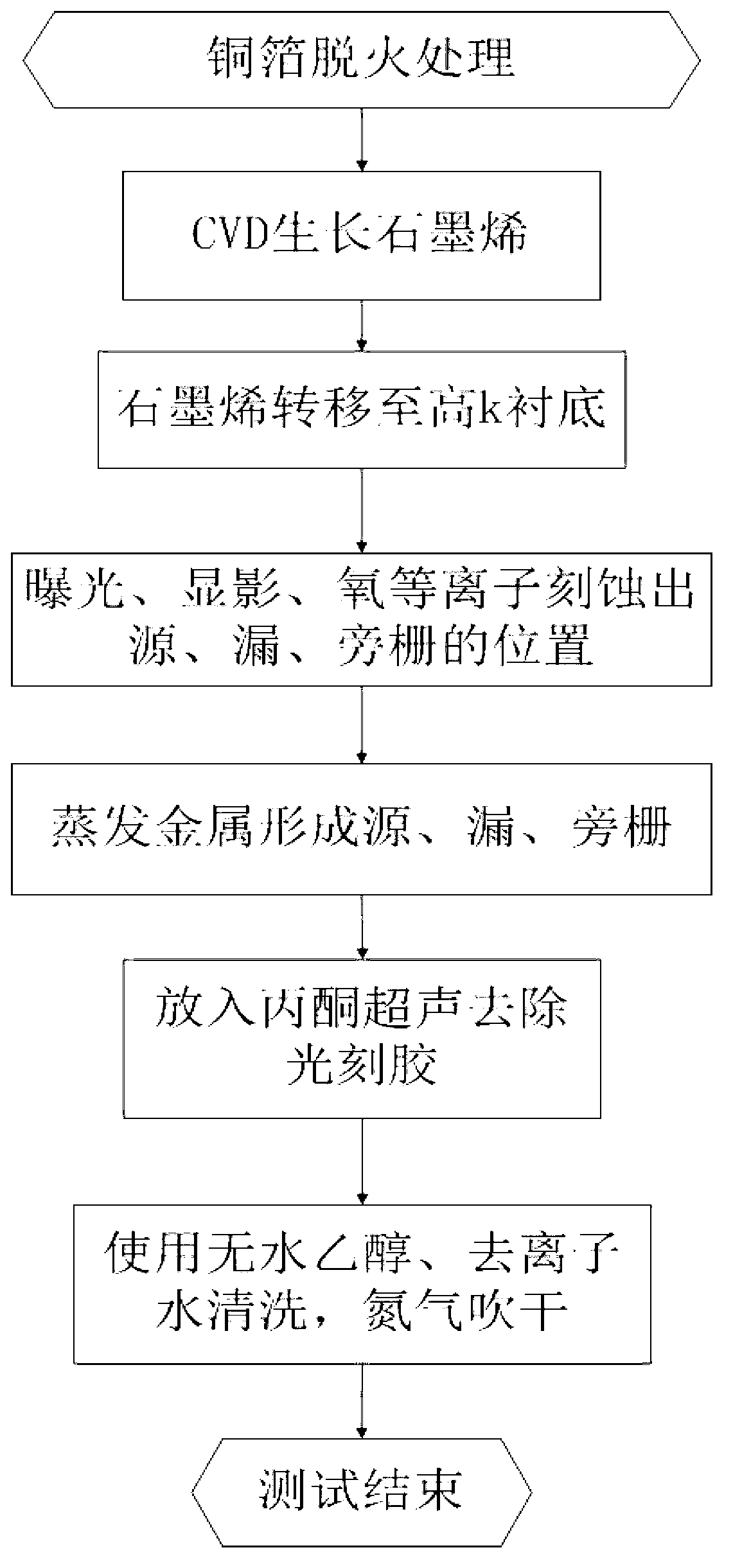

[0028] The realization steps of the present invention are as follows:

[0029] Step 1: Put the copper foil into the reaction chamber, and the reaction chamber is evacuated until the pressure is lower than 0.01 Pa. H was introduced into the reaction chamber with a flow rate of 10 sccm 2 , raise the temperature in the reaction chamber to 900°C, and perform thermal annealing on the copper foil, the annealing time is 60min;

[0030] Step 2: feed flow into reaction chamber as H of 50 sccm and CH of 10 sccm, grow graphene by chemical vapor deposition CVD for 15 min;

[0031] Step 3: After the reaction chamber is naturally cooled to room temperature, the growth sample is taken out, and polymethyl methacrylate PMMA is spin-coated on the graphene surface to form a laminated structure sample of copper foil-graphene-PMMA;

[0032] Step 4: Air-dry the laminated structure sample of the copper foil-graphene-PMMA, then make the PMMA face up to float in the concentration of 60g / L (NH 4 ) ...

Embodiment 2

[0039] The realization steps of the present invention are as follows:

[0040] Step A: Put the copper foil into the reaction chamber, and the reaction chamber is evacuated until the pressure is lower than 0.01 Pa. Introduce H2 with a flow rate of 15 sccm into the reaction chamber, raise the temperature in the reaction chamber to 950°C, and perform thermal annealing on the copper foil for 40 minutes;

[0041] Step B: feed into the reaction chamber H2 with a flow rate of 100 sccm and CH with a flow rate of 15 sccm, and grow graphene by chemical vapor deposition CVD for 10 min;

[0042] Step C: After the reaction chamber is naturally cooled to room temperature, the growth sample is taken out, and polymethyl methacrylate PMMA is spin-coated on the graphene surface to form a laminated structure sample of copper foil-graphene-PMMA;

[0043] Step D: air-dry the laminated structure sample of described copper foil-graphene-PMMA, then make PMMA face up and float in the (NH 4 ) 3 (S ...

Embodiment 3

[0050] The realization steps of the present invention are as follows:

[0051] Step 1: Put the copper foil into the reaction chamber, and the reaction chamber is evacuated until the pressure is lower than 0.01 Pa. Introduce H2 with a flow rate of 20 sccm into the reaction chamber, raise the temperature in the reaction chamber to 1000°C, and perform thermal annealing on the copper foil for 20 minutes;

[0052] Step 2: Introduce H into the reaction chamber with a flow rate of 200 sccm 2 and CH at a flow rate of 20 sccm 4 , grow graphene by chemical vapor deposition CVD for 10 minutes;

[0053] Step 3: After the reaction chamber is naturally cooled to room temperature, the growth sample is taken out, and polymethyl methacrylate PMMA is spin-coated on the graphene surface to form a laminated structure sample of copper foil-graphene-PMMA;

[0054] Step 4: air-dry the laminated structure sample of described copper foil-graphene-PMMA, then make PMMA face up and float in the (NH 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com