Application of astragalus polysaccharide to preparation of silage

A technology of astragalus polysaccharide and silage, which is applied in the application, animal feed, animal feed and other directions, can solve problems such as no public use, and achieve the effects of improving quality, reducing mass use, and improving production performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

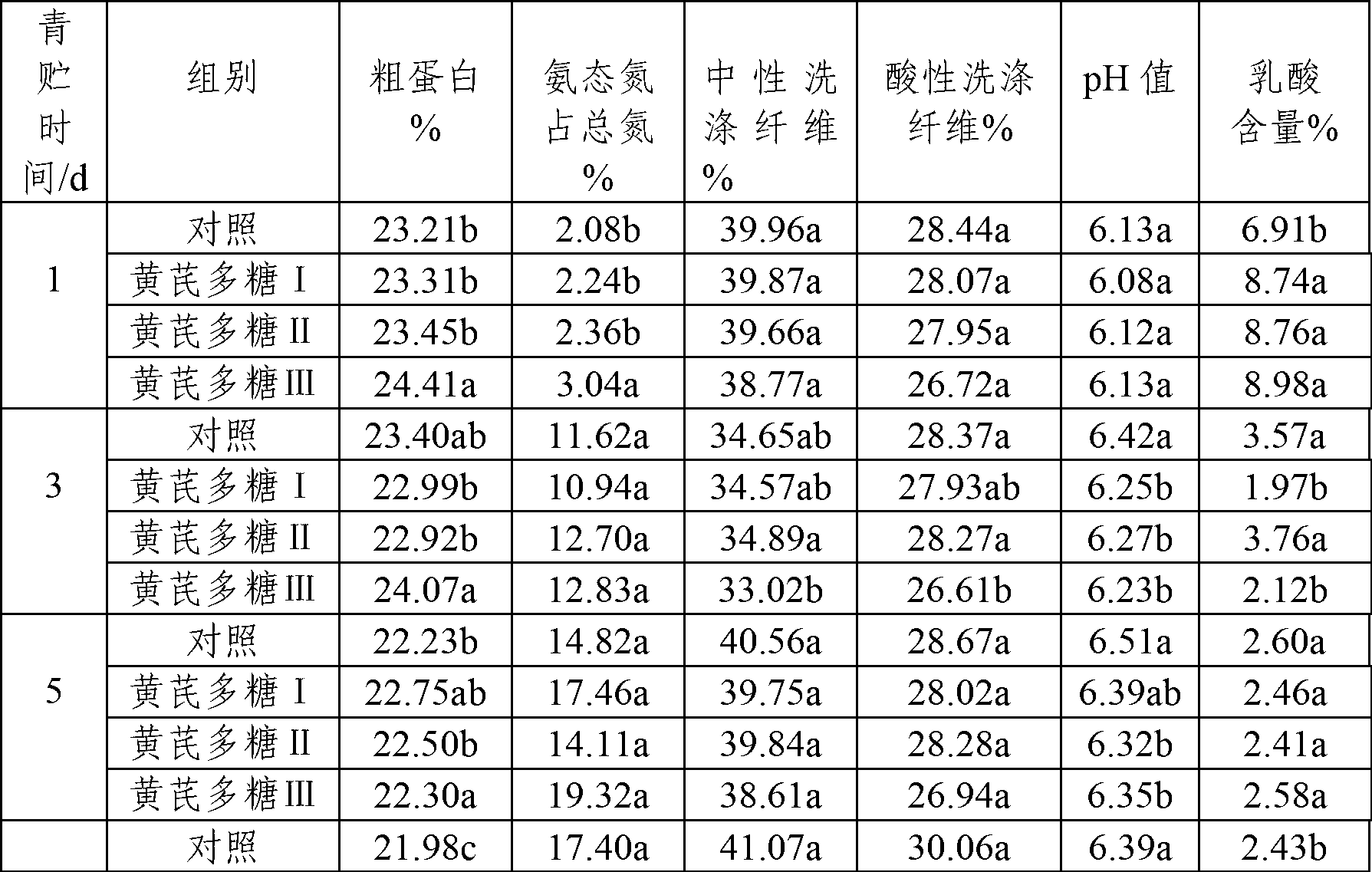

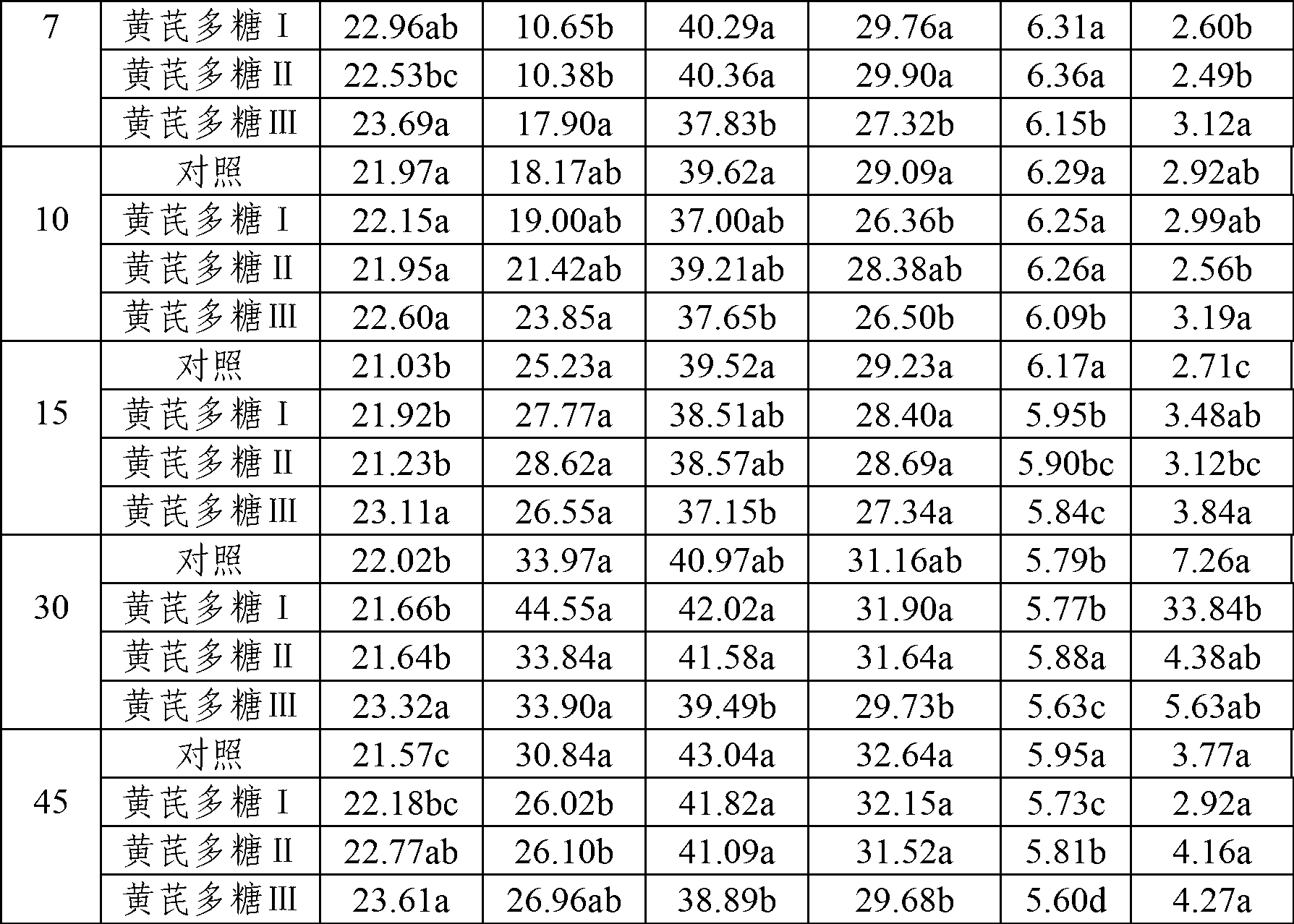

[0035] Example 1: Adding 0.001-0.004% of astragalus polysaccharide to prepare alfalfa silage

[0036] 1. Preparation of Leguminous Grass Silage Additives

[0037] Accurately weigh 100 mg of astragalus polysaccharide (dry weight), add 100 g of water to dissolve it fully, and obtain 100% astragalus polysaccharide stock solution (mass concentration is 1 mg / mL), store it in a refrigerator at 4 °C, and the 100% astragalus polysaccharide stock solution is ready For silage additives.

[0038] 2. Preparation of alfalfa silage with astragalus polysaccharide as an additive of leguminous forage silage and its effect detection

[0039] 1. Preparation of Algonquin alfalfa silage

[0040] The silage additive of step 1 is added to Algonquin alfalfa silage according to the proportion of astragalus polysaccharides being 0.001%, 0.002% and 0.004% of the fresh grass of Algonquin alfalfa, and the Algonquin alfalfa silage is prepared. The specific method as follows:

[0041] Take the fresh Alg...

Embodiment 2

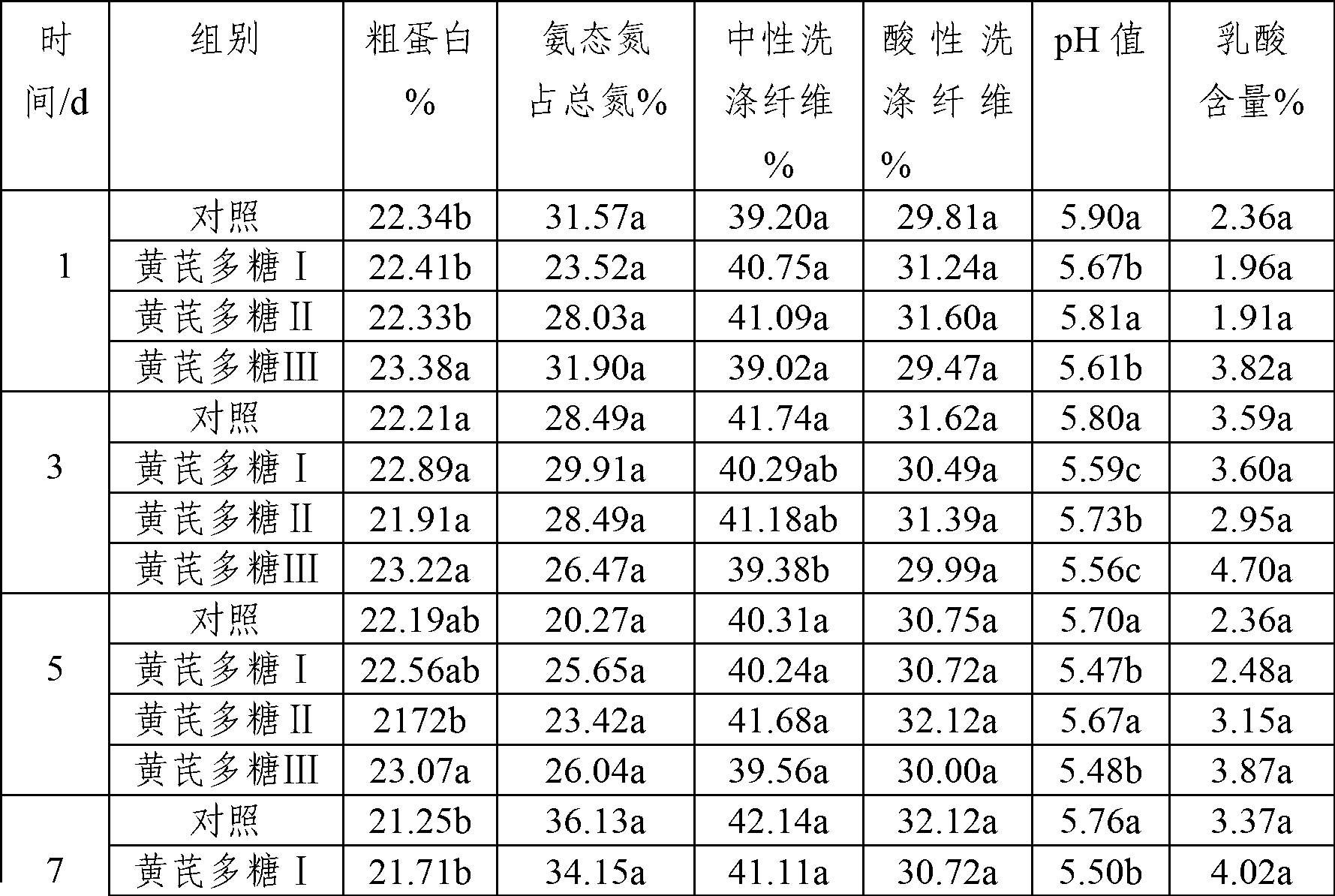

[0088] Example 2: Adding 0.005% of astragalus polysaccharide to prepare alfalfa silage

[0089] 1. Preparation of alfalfa silage

[0090] The silage additive in Step 1 of Example 1 was added to Medicago mellifera at a ratio of 0.005% of the fresh grass of Medicago sativa with astragalus polysaccharide to prepare silage. Labeled as Astragalus polysaccharide IV.

[0091] Spray the aqueous solution prepared according to the above-mentioned addition amount into 6.6kg of alfalfa fresh grass (water content is 70%), then mix the fresh grass and put it into a 130cm×22cm polyethylene silage bag, and seal it with a SINBO vacuum sealing machine , Carry out silage fermentation at room temperature (25-38°C). Put it at room temperature, and then take samples during silage and 1, 3, 5, and 7 days after opening (60 days after silage) for laboratory analysis, mainly analyzing crude protein, ammoniacal nitrogen, neutral detergent fiber, acid washing Fiber, pH, lactic acid and Lactobacillus c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com