Fish skin collagen based composite sponge and preparation method thereof

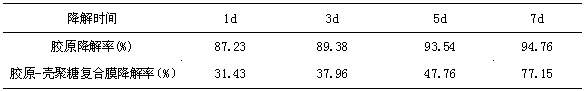

A technology of composite sponge and fish skin collagen is applied in the field of fish skin collagen-based composite sponge and its preparation, which can solve the problems of rapid degradation and poor flexibility, and achieve the effects of simple preparation process, good hygroscopicity, low price and easy availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the preparation of fish skin collagen-based composite sponge

[0023] 1) Weigh 50g of chopped and washed silver carp skin and put it in 1000mL0.01mol / LNaOH solution (containing 1mLH 2 o 2 ), stirred and soaked at 4°C for 48h, washed with water until neutral; put the washed fish skin in 300mL distilled water and 30mL isopropanol, stirred and soaked at 4°C for 4h, washed with water until neutral; weighed 25.6gNaCl and dissolved it in 1000mL water, then soak the fish skin in NaCl solution for 10 hours, centrifuge, remove the waste liquid, and obtain the pretreated minced fish skin.

[0024] 2) Mix the above minced fish skin with 500mL deionized water, homogenate for 15min, add 1.5g pepsin, adjust the pH to 2.0, enzymatically hydrolyze at 10°C for 10h, filter, centrifuge the filtrate at 8000r / min for 20min at low temperature, and take the supernatant .

[0025] 3) Add 2% acetic acid solution to the supernatant, filter, dialyze with 2% acetic acid solution a...

Embodiment 2

[0027] Embodiment 2: the preparation of fish skin collagen-based composite sponge

[0028] 1) Weigh 50g of chopped and washed silver carp skin and put it in 1000mL0.01mol / LNaOH solution (containing 5mLH 2 o 2 ), stirred and soaked at 4°C for 24h, washed with water until neutral; put the washed fish skin in 300mL distilled water and 30mL isopropanol, stirred and soaked at 4°C for 4h, washed with water until neutral; weighed 25.6gNaCl and dissolved it in 1000mL water, then soak the fish skin in NaCl solution for 10 hours, centrifuge, remove the waste liquid, and obtain the pretreated minced fish skin.

[0029] 2) Mix the above minced fish skin with 500mL deionized water, homogenate for 15min, add 1.3g pepsin, adjust the pH to 3.0, enzymolyze at 6°C for 20h and filter, centrifuge the filtrate at 8000r / min for 20min at low temperature, and take the supernatant .

[0030] 3) Add 2% acetic acid solution to the supernatant, filter, dialyze with 2% acetic acid solution as the exter...

Embodiment 3

[0032] Embodiment 3: the preparation of fish skin collagen-based composite sponge

[0033] 1) Weigh 50g of chopped and washed silver carp skin and put it in 1000mL0.01mol / LNaOH solution (containing 10mLH 2 o 2 ), stirred and soaked at 4°C for 12h, washed with water until neutral; put the washed fish skin in 300mL distilled water and 30mL isopropanol, stirred and soaked at 4°C for 4h, washed with water until neutral; weighed 25.6gNaCl and dissolved it in 1000mL water, then soak the fish skin in NaCl solution for 10 hours, centrifuge, remove the waste liquid, and obtain the pretreated minced fish skin.

[0034] 2) Mix the above minced fish skin with 500mL deionized water, homogenate for 15min, add 1.0g pepsin, adjust the pH to 4.0, enzymolyze at 4°C for 30h and filter, centrifuge the filtrate at 8000r / min for 20min at low temperature, and take the supernatant .

[0035] 3) Add 2% acetic acid solution to the supernatant, filter, dialyze with 2% acetic acid solution as the exte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com