Wet-type oxidative denitration and energy utilization method of smoke

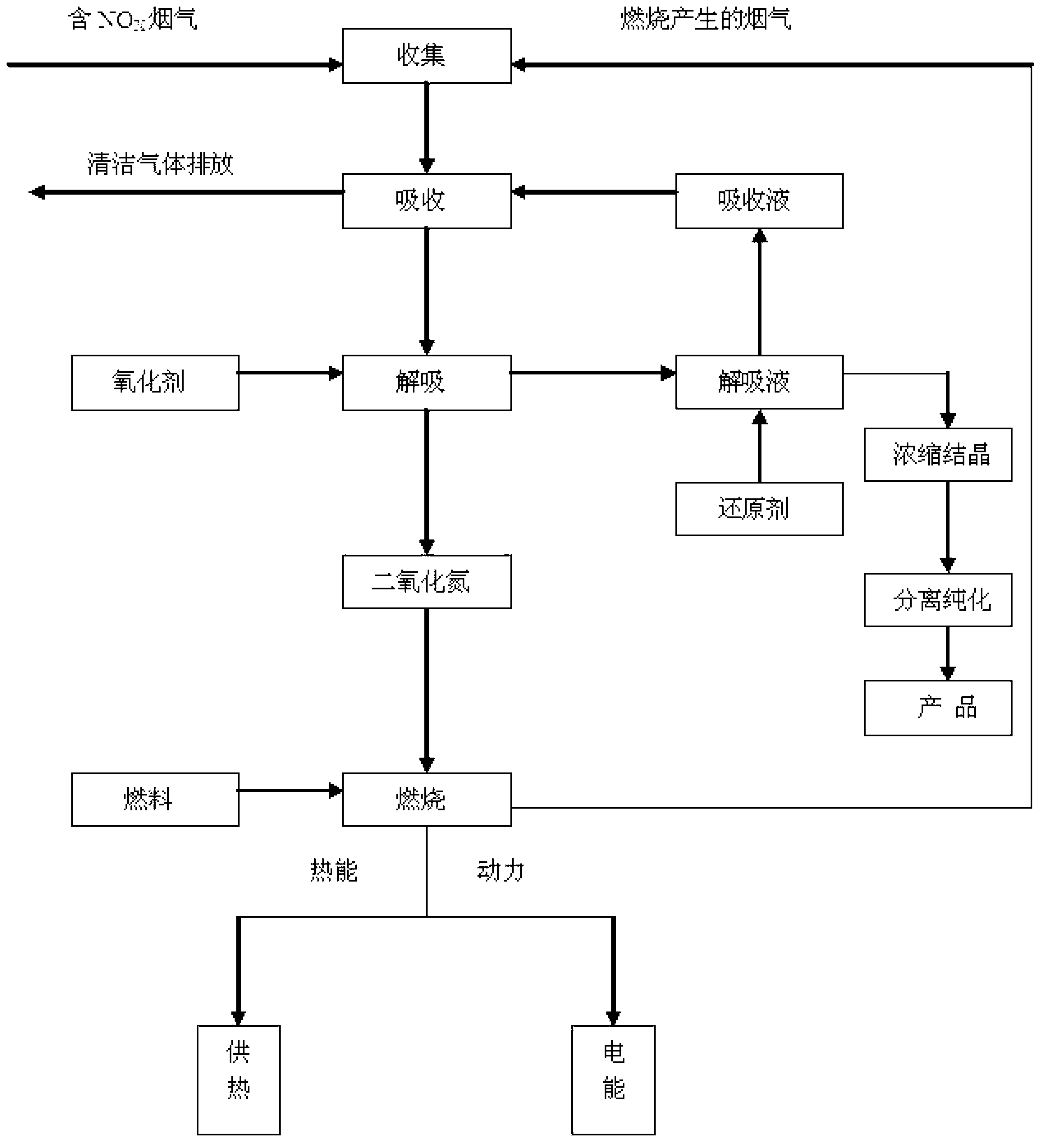

一种湿式氧化、能源化的技术,应用在一氧化二氮捕获、化学仪器和方法、分离方法等方向,能够解决运行费用高、易中毒、催化剂强度不够等问题,达到经济效益巨大的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 1L of ferric chloride solution with a hydrogen ion concentration of 1mol / L and a ferric iron concentration of 2.7mol / L, and then at 30°C and at one atmosphere, pass in nitric oxide gas with an amount of 1.7mol, The reaction time is 0-4h until the absorption liquid becomes dark brown and stops. After standing for 1h, the absorption liquid is filled with oxygen

[0025] 1.35mol, the reaction time is 3-5h, the released nitrogen dioxide gas is passed into the combustion furnace and burned, 30g kerosene is sprayed, and the temperature difference of the combustion furnace is 180°C.

Embodiment 2

[0027] Take 300ml of ferric chloride solution with a hydrogen ion concentration of 0.7mol / L and a ferric iron concentration of 1.3mol / L, and then at 30°C and one atmosphere pressure, pass in nitric oxide gas, the amount of pass is 0.39mol The reaction time is 0-3h until the absorption liquid turns dark brown and stops. After standing for 1h, the absorption liquid is filled with 0.22mol of oxygen, and the reaction time is 0-5h. The released nitrogen dioxide gas is passed into the combustion furnace and burned. Inject 22g of kerosene, and the temperature difference of the combustion furnace is 120°C.

Embodiment 3

[0029] Take 300ml of ferric chloride solution with a hydrogen ion concentration of 0.7 mol / L and a ferric iron concentration of 1.3 mol / L, and then at 30°C, pass in nitric oxide gas, the passing volume is 0.39 mol, the reaction time is 0-3h, until the absorption liquid turns dark brown and stop. After standing for 1h, the absorption liquid is filled with oxygen 0.22mol, and the reaction time is 0-5h. The released nitrogen dioxide gas is burned in the combustion furnace and sprayed into kerosene. 22g, the heating temperature difference of the combustion furnace is 120°C; the combustion pressure in the sealed pressure furnace can be as high as about 28 atmospheres.

[0030] A flue gas wet oxidation denitrification and energy utilization method provided by the present invention has the following beneficial effects:

[0031] 1. Change the existing treatment process to achieve denitrification, while reducing the investment cost and device scale, and reducing the operating cost. It is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com