Cleaning method of polycrystalline silicon raw material

A polysilicon and raw material technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of high cost, achieve low cost, reduce the content of metal impurities and boron, and improve the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

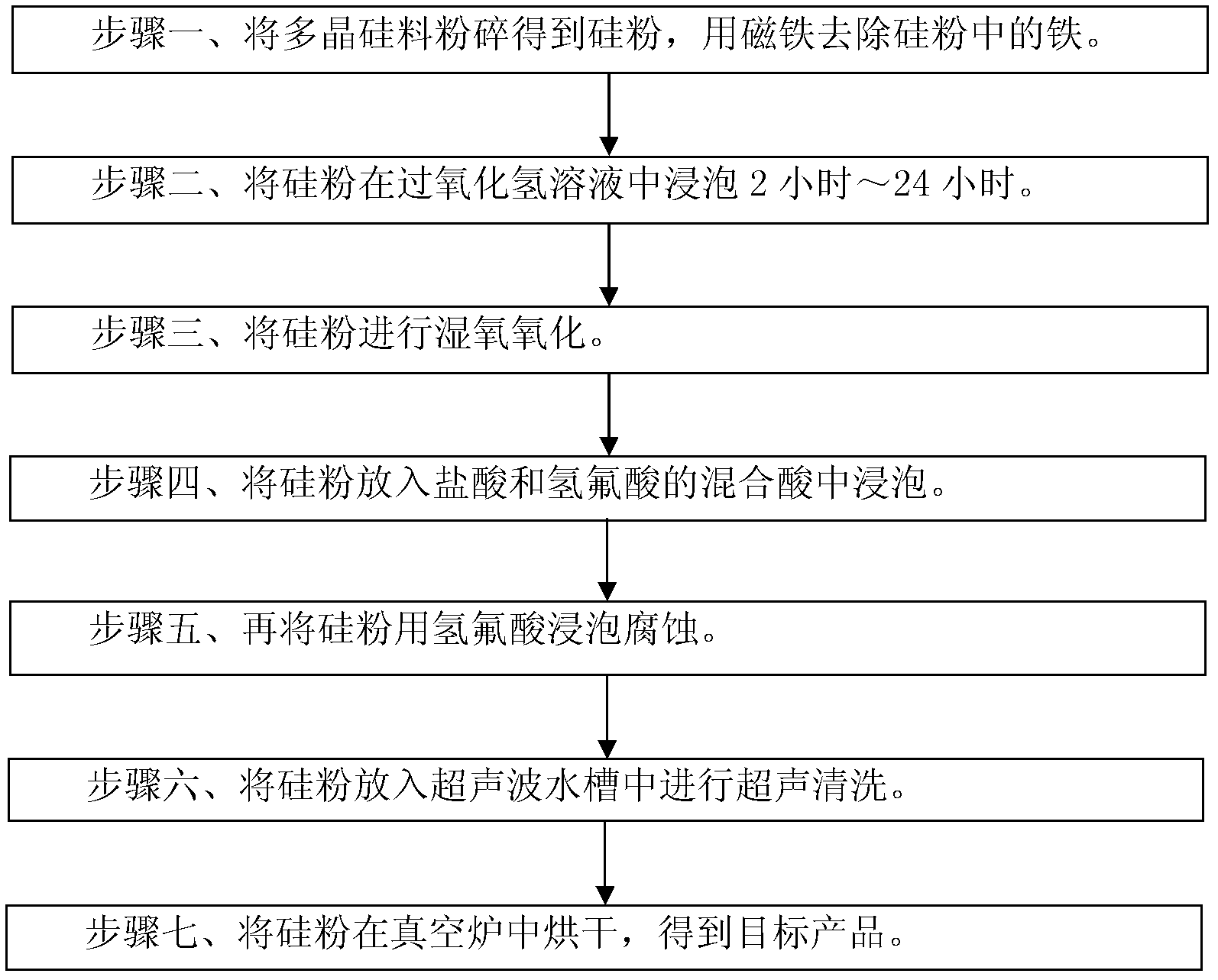

Method used

Image

Examples

Embodiment 1

[0035] Preferred embodiment 1 of the present invention is:

[0036] The polysilicon material containing impurities is crushed first, and the mesh size of the sieved silicon powder is 50 mesh, and then the iron in the silicon material is absorbed by a magnet. Then put the silicon powder into 40% hydrogen peroxide solution and soak for 24 hours. Then put the silicon powder into a high-temperature container, and then put the container into a high-temperature furnace for wet oxygen oxidation. The oxygen flow rate is 1000 ml / min, the oxidation temperature is 1200 ° C, and the oxidation time is 1 hour. The appearance of silica fume is purple or dark red, and then cools down. Put the silicon powder taken out after cooling into the mixed acid whose concentration is 20% hydrochloric acid and 40% hydrofluoric acid and soak for 6 hours to remove impurities such as oxide layer and iron in the sample, wherein the hydrochloric acid and The volume ratio of hydrofluoric acid is 3:1; the sil...

Embodiment 2

[0038] Preferred embodiment 2 of the present invention is:

[0039] The polysilicon material containing impurities is crushed first, and the sieved silicon powder has a mesh size of 200 mesh, and then the iron in the silicon material is absorbed by a magnet. Then put the silicon powder into a hydrogen peroxide solution with a concentration of 30% and soak for 12 hours. Then put the silicon powder into a high-temperature container, and then put the container into a high-temperature furnace for wet oxygen oxidation. The oxygen flow rate is 1000 ml / min, the oxidation temperature is 800°C, and the oxidation time is 8 hours. The appearance of silica fume is purple or dark red, and then cools down. Put the silicon powder taken out after cooling into the mixed acid whose concentration is 30% hydrochloric acid and 40% hydrofluoric acid and soak for 4 hours to remove impurities such as oxide layer and iron in the sample, wherein the hydrochloric acid and The volume ratio of hydrofluo...

Embodiment 3

[0041] Preferred embodiment 3 of the present invention is:

[0042]The polysilicon material containing impurities is crushed first, and the mesh size of the sieved silicon powder is 400 mesh, and then the iron in the silicon material is absorbed by a magnet. Then put the silicon powder into 20% hydrogen peroxide solution and soak for 2 hours. Then put the silicon powder into a high-temperature container, and then put the container into a high-temperature furnace for wet oxygen oxidation. The oxygen flow rate is 1000 ml / min, the oxidation temperature is 400°C, and the oxidation time is 24 hours. The appearance of silica fume is purple or dark red, and then cools down. Soak the silicon powder taken out after cooling in a mixed acid with a concentration of 30% hydrochloric acid and 40% hydrofluoric acid to remove impurities such as oxide layer and iron in the sample, wherein the hydrochloric acid and hydrofluoric acid in the mixed acid The volume ratio of the acid is 1:1; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com