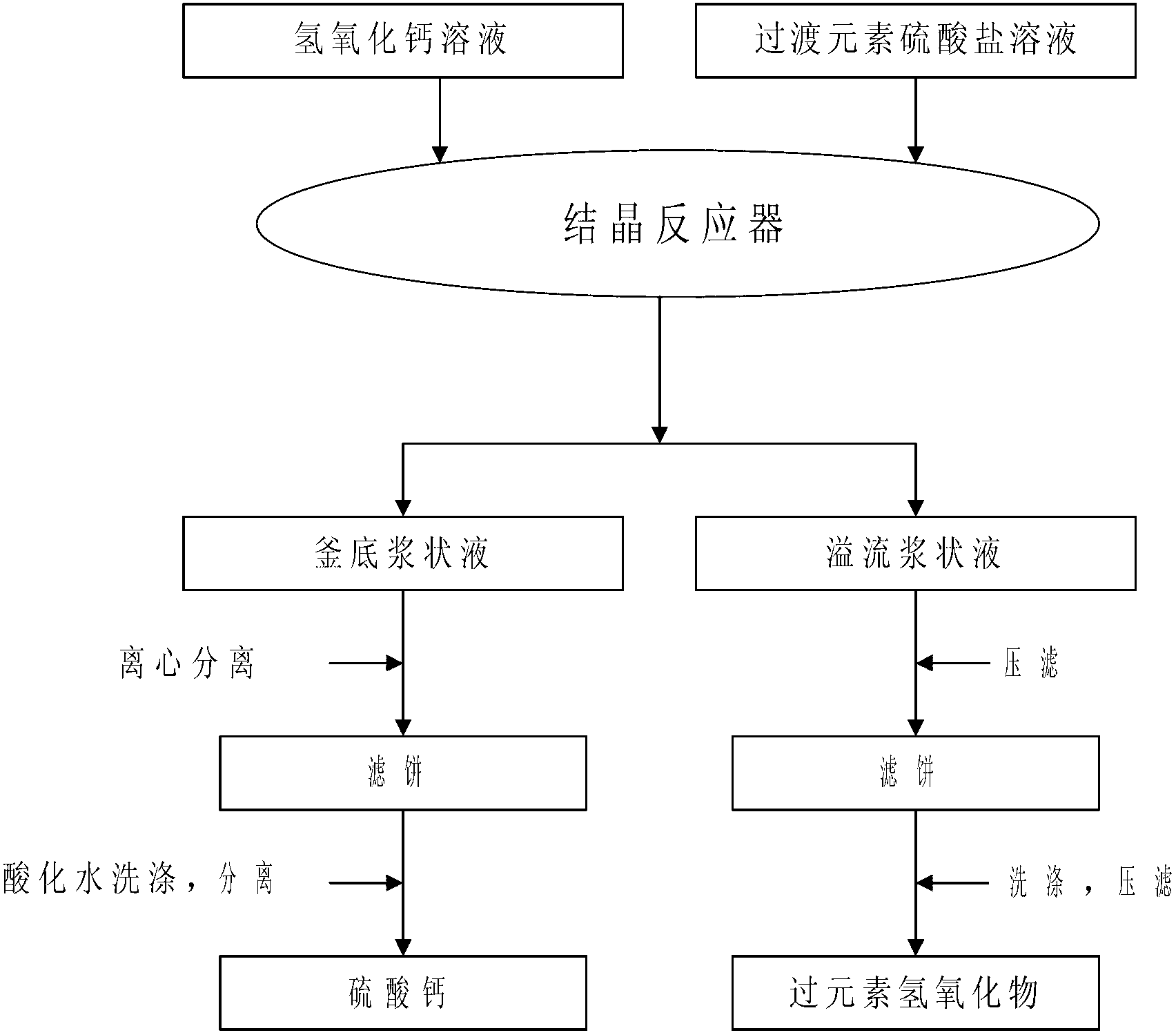

Method for preparing transition element hydroxide by using calcium hydroxide

A transition element, calcium hydroxide technology, applied in the directions of nickel oxide/nickel hydroxide, zinc oxide/zinc hydroxide, copper oxide/copper hydroxide, etc., can solve problems such as difficult and effective separation, and achieve high separation efficiency and process. Simple, inhibits the effect of spontaneous nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

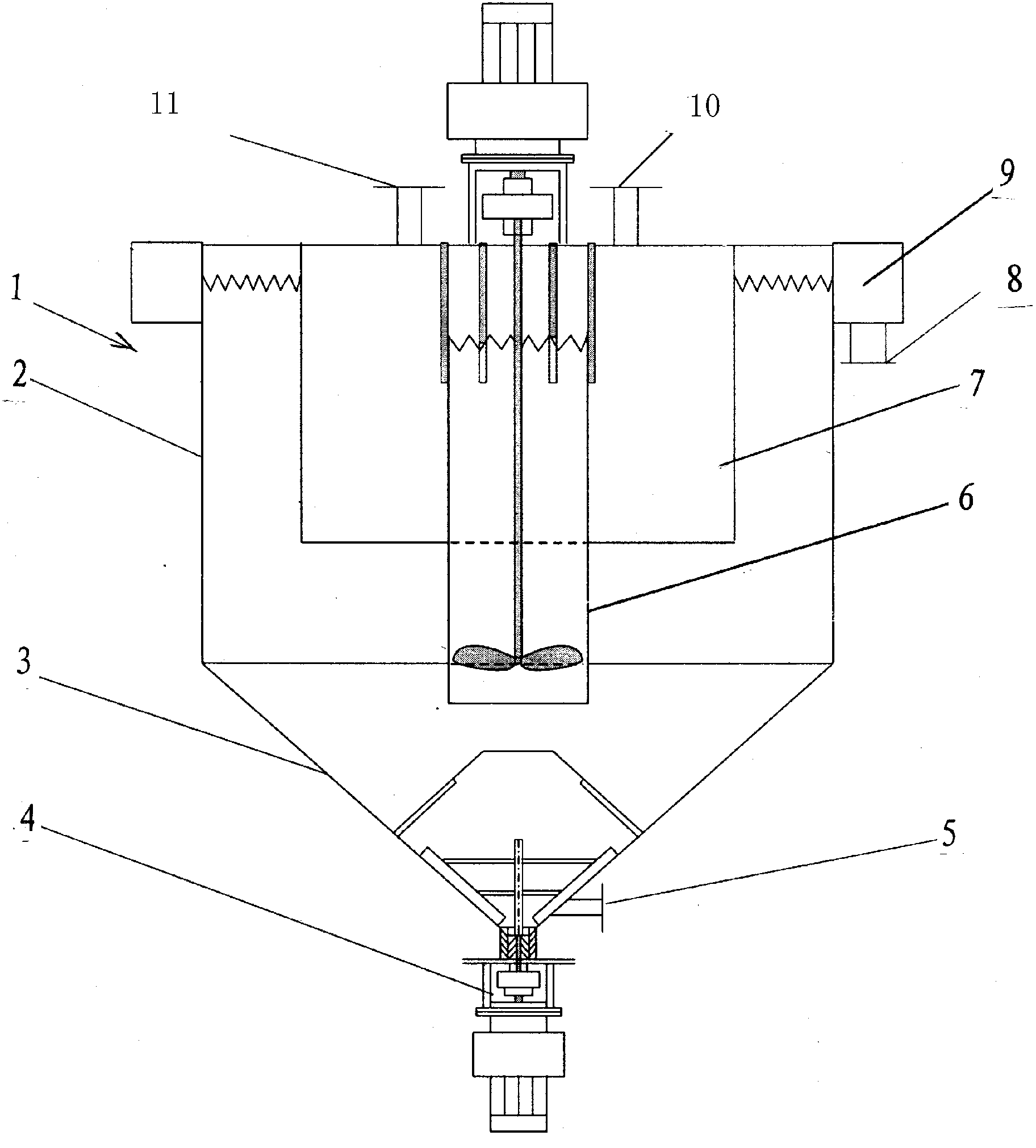

[0024] Example 1: Preparation of cobalt hydroxide

[0025] Take cobalt sulfate solution and calcium hydroxide solution and analyze the composition of cobalt sulfate solution as: SO 4 2- 0.62mol / L, Co 2+ 0.62mol / L; the composition of calcium hydroxide solution: Ca 2+ 1.20mol / L, OH - 2.40mol / L.

[0026] The cobalt sulfate solution and the calcium hydroxide solution were continuously fed into the crystallization reactor simultaneously from the transition element sulfate solution inlet 10 and the calcium hydroxide solution inlet 11 respectively, and the feed ratio was the cobalt ion Co in the cobalt sulfate solution. 2+ With hydroxide ion OH in calcium hydroxide solution - The molar ratio is 1:2, and the feed rates of cobalt sulfate solution and calcium hydroxide solution are 3.3L / h and 1.71L / h, respectively. When the feed liquid level in the crystallizer exceeds the upper mouth of the circulating lifting device 6, the circulating lifting device 6 is turned on. The circulating liquid l...

Embodiment 2

[0031] Example 2: Preparation of nickel hydroxide

[0032] Take nickel sulfate solution and calcium hydroxide solution, and analyze the composition of nickel sulfate solution as: SO 4 2- 0.83mol / L, Ni 2+ 0.83mol / L; the composition of calcium hydroxide solution: Ca 2+ 1.50mol / L, OH - 3.00mol / L.

[0033] The nickel sulfate solution and the calcium hydroxide solution were continuously fed into the crystallization reactor simultaneously from the transition element sulfate solution inlet 10 and the calcium hydroxide solution inlet 11 respectively, and the feed ratio was the nickel ion Ni in the nickel sulfate solution. 2+ With hydroxide ion OH in calcium hydroxide solution - The molar ratio is 1:3, and the feed rates of nickel sulfate solution and calcium hydroxide solution are 1.40L / h and 1.17L / h, respectively. When the feed liquid level in the crystallizer exceeds the upper mouth of the circulating lifting device 6, the circulating lifting device 6 is turned on. The circulating liqui...

Embodiment 3

[0038] Example 3: Preparation of copper hydroxide

[0039] Take copper sulfate solution and calcium hydroxide solution, analyze the composition of copper sulfate solution as: SO 4 2- 0.96mol / L, Cu 2+ 0.96mol / L; the composition of calcium hydroxide solution: Ca 2+ 1.98mol / L, OH - 3.96mol / L.

[0040] The copper sulfate solution and the calcium hydroxide solution were continuously fed into the crystallization reactor simultaneously from the transition element sulfate solution inlet 10 and the calcium hydroxide solution inlet 11 respectively, and the feed ratio was copper ion Cu in the copper sulfate solution. 2+ With hydroxide ion OH in calcium hydroxide solution - The molar ratio is 1:4, and the feed rates of copper sulfate solution and calcium hydroxide solution are 2.48L / h and 2.40L / h, respectively. When the feed liquid level in the crystallizer exceeds the upper mouth of the circulating lifting device 6, the circulating lifting device 6 is turned on. The circulating liquid liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com