Preparation method for nanosheet of uniformly dispersed layered double hydroxides (LDHs)

A hydrotalcite, monolithic technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as unfavorable applications, and achieve the effects of wide application range, friendly production environment, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

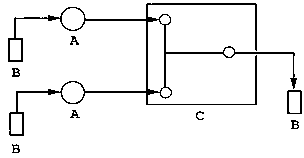

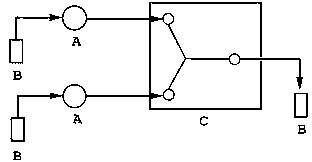

Method used

Image

Examples

Embodiment 1

[0023] This embodiment first weighs 2.250g Al(NO 3 ) 3 9H 2 O and 3.078g Mg(NO 3 ) 2 ·6H 2 O was dissolved in 20ml of water to obtain a mixed salt solution, in which, Al 3+ with Mg 2+ The molar ratio of the solution is 1:2; the dilute ammonia solution of 7wt% is prepared by conventional technology; at a reaction temperature of 25°C, the flow rate of the mixed salt solution and the dilute ammonia solution is 15ml / min, and in the microreactor Mixing reaction in middle to obtain precipitate, centrifuge the precipitate and wash with distilled water, repeat three times, and the obtained product is homogeneously dispersed hydrotalcite-like nano single sheet.

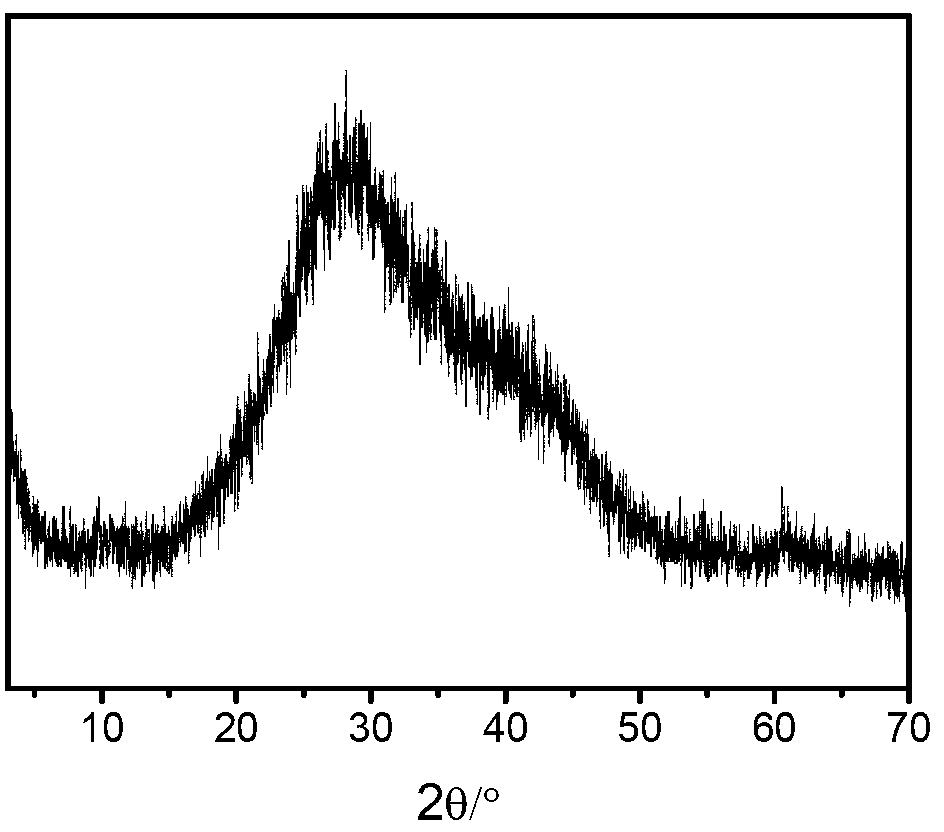

[0024] In this example, the XRD-6000 X-ray powder diffractometer of Shimadzu Corporation was used to characterize the crystal structure of the homogeneously dispersed hydrotalcite-like nano-monolithic sheet. image 3 The XRD spectrum of the homogeneously dispersed hydrotalcite-like nano-monolithic sheet, it can be seen ...

Embodiment 2

[0026] This embodiment first weighs 0.250g Al(NO 3 ) 3 9H 2 O and 0.397g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 20ml of water to obtain a mixed salt solution, in which, Al 3+ with Zn 2+ The mol ratio of the solution is 1:2; the aqueous sodium hydroxide solution of 0.20mol / L is adopted in the preparation of conventional technology, and at a reaction temperature of 30°C, the flow rate of the mixed salt solution and the aqueous sodium hydroxide solution is 20ml / min. Mixing and reacting in a microreactor to obtain precipitates, centrifuging the precipitates and washing them with distilled water, repeating three times, the obtained product is uniformly dispersed hydrotalcite-like nano-sheets.

[0027] In this example, the XRD-6000 X-ray powder diffractometer of Shimadzu Corporation was used to characterize the crystal structure of the homogeneously dispersed hydrotalcite-like nano-monolithic sheet. Figure 4 For the XRD spectrogram of the homogeneously dispersed hydrotalcite-l...

Embodiment 3

[0029] This embodiment first weighs 0.750g Al(NO 3 ) 3 9H 2 O and 1.539g Mg(NO 3 ) 2 ·6H 2 O is dissolved in 20ml of water to obtain a mixed salt solution, wherein, Al 3+ with Mg 2+ The mol ratio of the solution is 1:3; the aqueous sodium hydroxide solution of 0.20mol / L is adopted in the preparation of conventional technology, and at a reaction temperature of 30°C, the flow rate of the mixed salt solution and the aqueous sodium hydroxide solution is 10ml / min. Mixing and reacting in a microreactor to obtain precipitates, centrifuging the precipitates and washing them with distilled water, repeating three times, the obtained product is uniformly dispersed hydrotalcite-like nano-sheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com