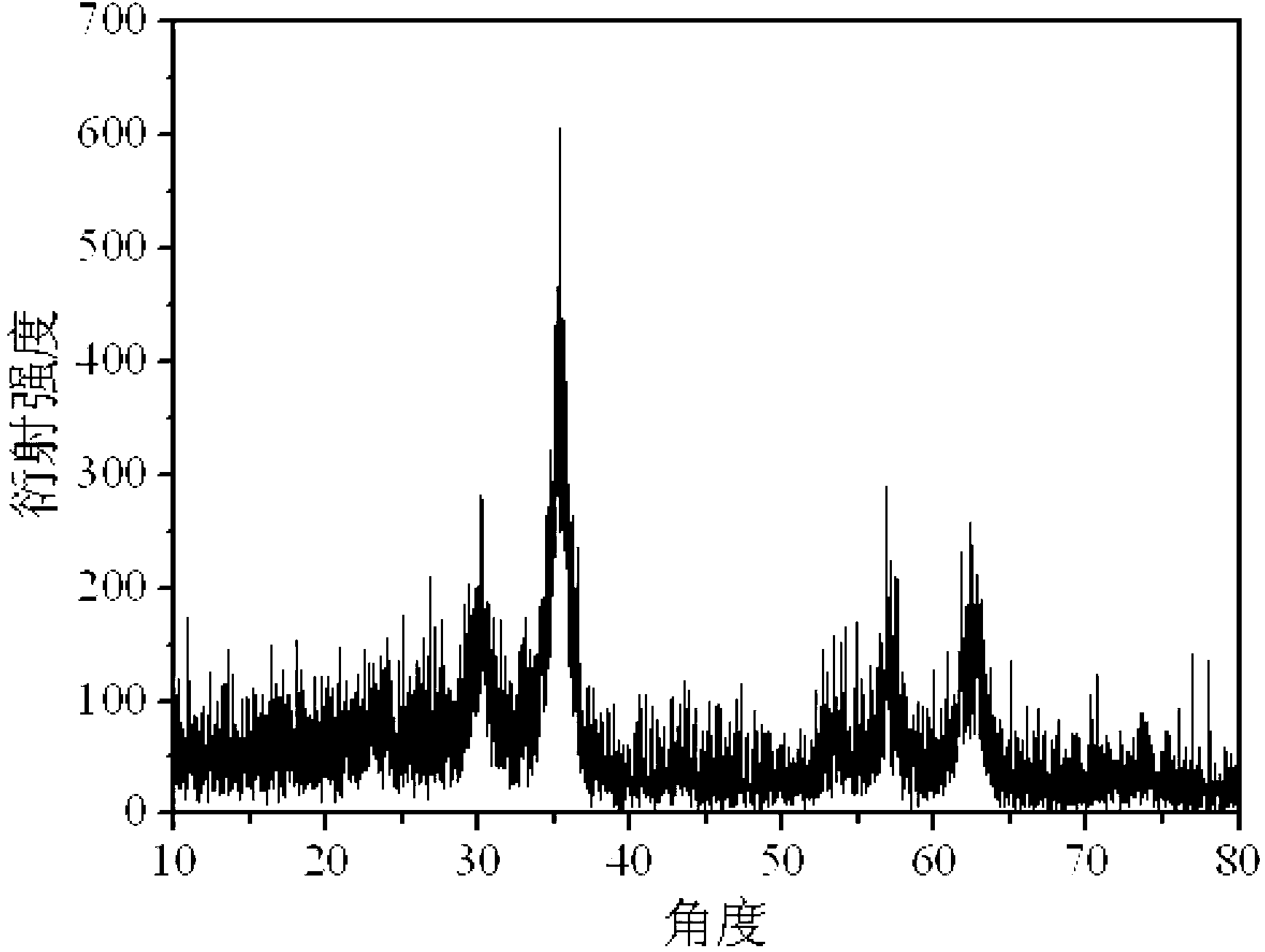

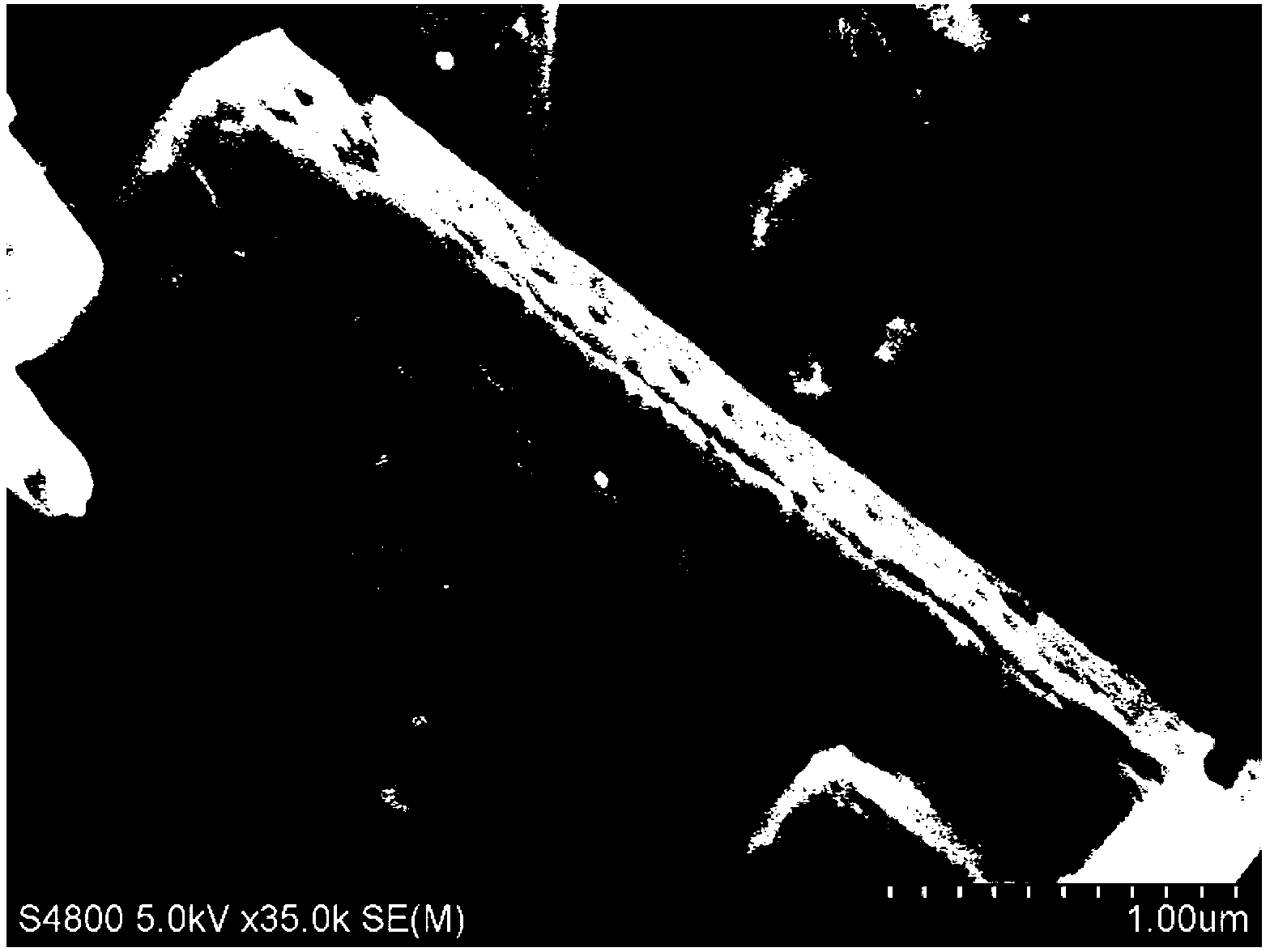

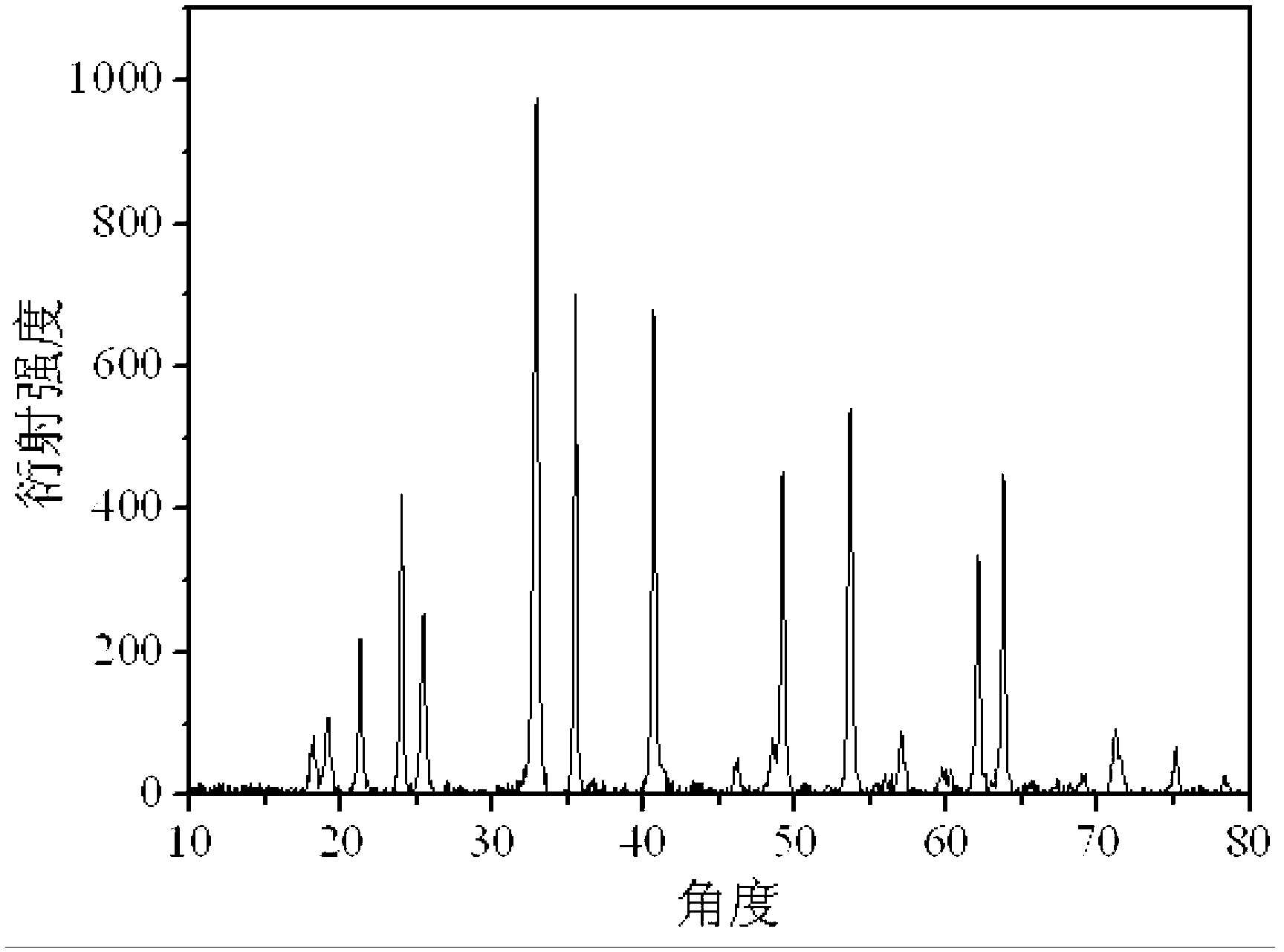

Preparation method of one-dimensional metal titanate nanorods

A technology of titanate and nanorods, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of low roughness factor, small specific surface area, uneven size and shape, etc., and achieve obvious pore size distribution and large roughness factor, the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0010] Embodiment 1: In this embodiment, a method for preparing a one-dimensional metal titanate nanorod is specifically completed according to the following steps:

[0011] 1. Preparation of metal salt ethylene glycol solution: Dissolve the inorganic metal salt completely in the alcohol solvent at a temperature of 25°C~35°C, and prepare an inorganic salt with a molar concentration of metal ions of 0.0025mol / L~0.01mol / L Alcoholic solution of metal salt; 2. Add titanium source: add titanium source to the alcohol solution of inorganic metal salt prepared in step 1 at a temperature of 25°C~35°C, and stir at a stirring speed of 100r / min~300r / min Stirring under the condition of min for 1h~3h, the precursor suspension was obtained; 3. Centrifugal separation and washing: the precursor suspension obtained in step 2 was centrifuged to obtain the metal titanate nanorod precursor. Wash the metal titanate nanorod precursor with absolute ethanol for 2 to 5 times, and then centrifuge at a s...

specific Embodiment approach 2

[0017] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the alcohol solvent described in step one is ethylene glycol, isopropanol, 1,3-propylene glycol, polyethylene glycol 400 and polyethylene glycol One of 600 or a mixture of several of them. Others are the same as the first embodiment.

[0018] When the alcohol solvent described in this embodiment is a mixture, the components are mixed in any ratio.

specific Embodiment approach 3

[0019] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the inorganic metal salt described in step one is magnesium acetate, cobalt acetate, zinc acetate, aluminum acetate, calcium acetate and manganese acetate One or a mixture of several of them. Others are the same as those in Embodiment 1 or 2.

[0020] When the inorganic metal salt described in this embodiment is a mixture, the components are mixed in any ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com