Synchronous degradation process and device for COD (Chemical Oxygen Demand) and N (Nitrogen) of high concentration wastewater in same pool

A high-concentration wastewater and process technology, applied in the direction of aerobic and anaerobic process treatment, can solve the problems of unstable COD compliance, narrow range, uneven aeration, etc., achieve stable water quality indicators and system operating parameters, and resist shocks Strong ability to harm and poison, improve COD and N degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0070] Example 1: A printing and dyeing factory active printing wastewater treatment, wastewater COD and total nitrogen concentration is high, the original treatment process is "adjustment tank + flocculation sedimentation tank + anaerobic tank + aerobic tank + flocculation sedimentation tank", the effluent COD Cr and ammonia nitrogen are not up to standard, and the present invention is applied for process adjustment.

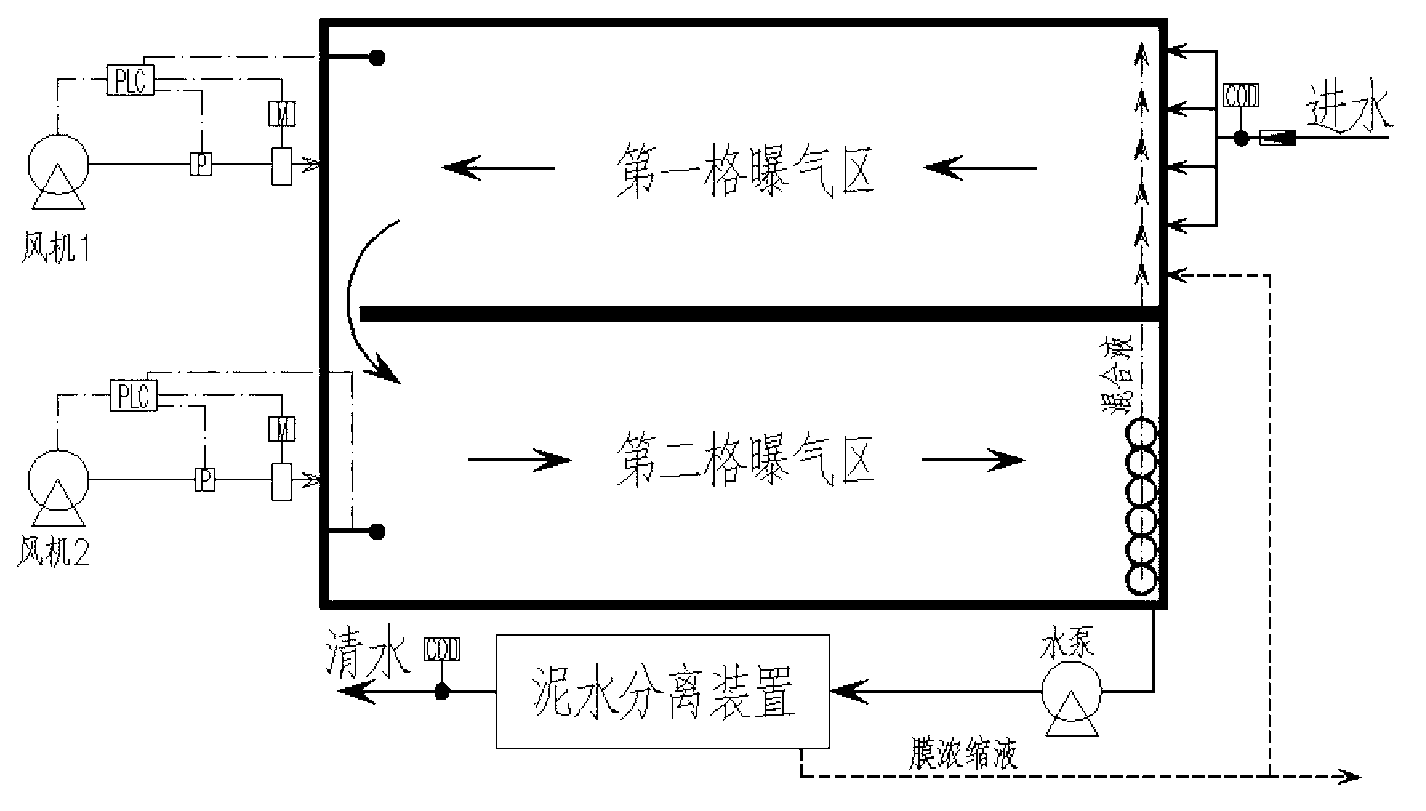

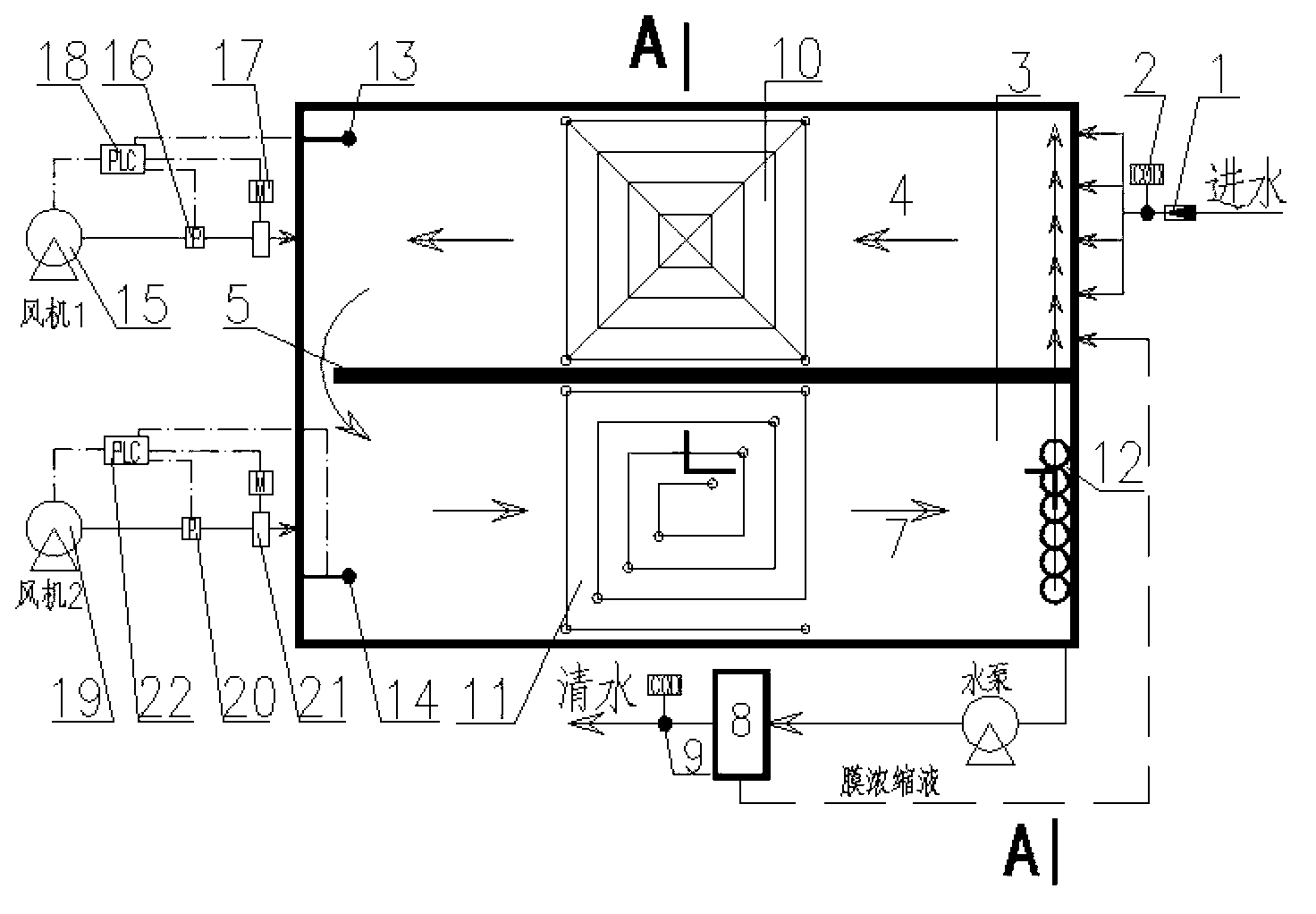

[0071] Technological process: regulating pool + synchronous degradation pool in the same pool.

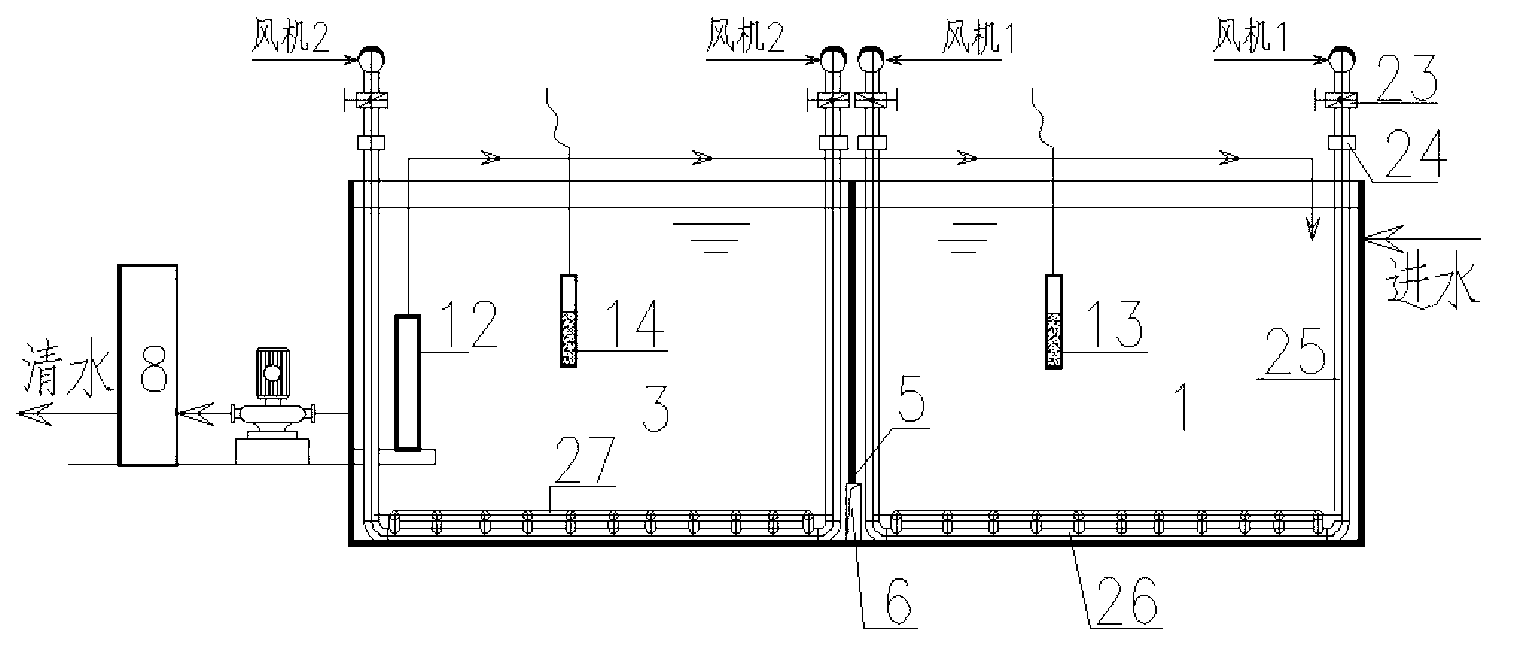

[0072] Process and device parameters: high-density back-type aeration; the dissolved oxygen range of the first aeration zone is 0.2~0.5mg / L, the biochemical residence time is 12 hours, the dissolved oxygen range of the second aeration zone is 0.3~0.9mg / L, The biochemical residence time is 63 hours; MLSS6300~6900mg / L in the aeration area of the biochemical tank; the mixed liquid reflux equipment is an air lift pump, and the reflux ratio is 60 times; the mud-water s...

example 2

[0082] Example 2: Wastewater treatment of a bean product factory has high concentrations of COD and total nitrogen in the wastewater. The original treatment process is "pre-sedimentation tank + anaerobic tank + aerobic tank + air flotation tank", and the effluent ammonia nitrogen exceeds the standard. The invention is used for process adjustment.

[0083] Technological process: regulating pool + synchronous degradation pool in the same pool.

[0084] Process and device parameters: high-density back-type aeration, the dissolved oxygen range of the first aeration zone is 0.2~0.5mg / L, the biochemical residence time is 10 hours, the dissolved oxygen range of the second aeration zone is 0.3~1.2mg / L, The biochemical residence time is 86 hours, the MLSS in the aeration area is 7400~8360mg / L, the mixed liquid reflux equipment is an air lift pump, and the reflux ratio is 106 times. The mud-water separation adopts a tubular ultrafiltration membrane, and the effluent water quality meets t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com