Environment-friendly wall material for interior wall decoration and preparation method of wall material

An environmentally friendly wall material and interior wall technology, applied in the field of interior wall decoration wall material and its preparation, can solve the problems of difficult to reuse, uneven distribution, low decomposition efficiency, etc., to prevent the generation of mold, prevent excessive dryness or humidity , The effect of purifying indoor air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Preparation of diatomite

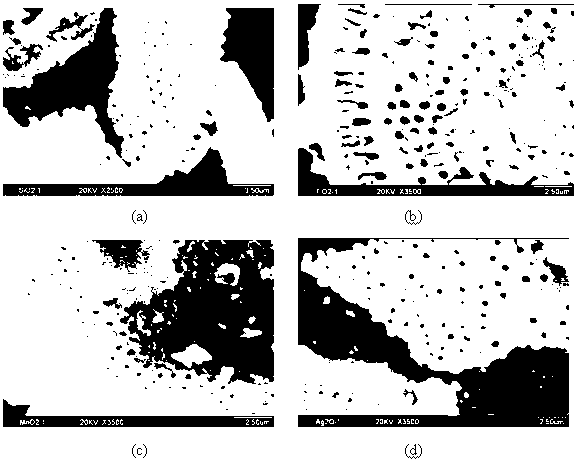

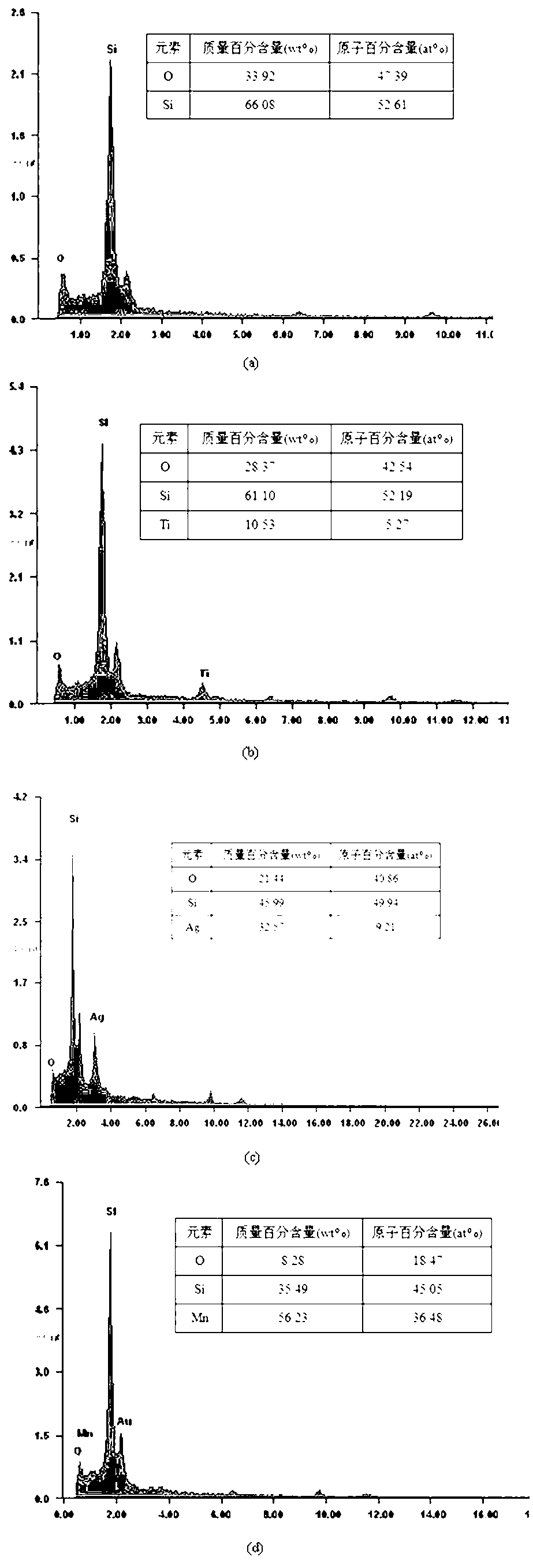

[0041] Take 100g of diatomite, grind it with a ball mill at 200rpm for 1h, separate and remove larger impurity particles with a 200-mesh screen, add 400g of water, stir for 30min, let stand for 10min, suck out the upper layer of turbid solution, and then filter the turbid solution. Put the filter cake into a beaker, add 35% hydrochloric acid solution, stir at 200 rpm for 1 hour at 70°C, and put it into a 150W ultrasonic cleaner. After 2 hours, adjust the pH value of the diatomite suspension to 3, take it out, filter, wash, and vacuum-dry the filter cake at 120°C for 2 hours, then put it in a muffle furnace for calcination at 600°C for 2 hours, and obtain a product with a high specific surface area after expansion. and high-porosity diatomite, the scanning electron microscope (SEM) picture and energy spectrum analysis (EDAX) picture respectively refer to the attached figure 1 (a) and attached figure 2 (a).

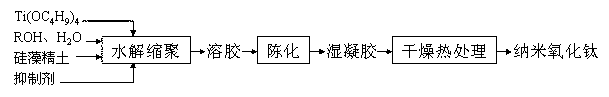

[0042] 2. Preparation of tita...

Embodiment 2

[0057] According to the method in Example 1, the original diatom earth was subjected to expansion treatment to obtain diatom concentrate with a high specific surface area.

[0058] Mix 25ml of absolute ethanol with 10ml of butyl titanate, stir at 200rpm for 10 minutes, then add 20g of diatomite, and stir vigorously for 10 minutes to form a slurry. Add 4ml of glacial acetic acid and 10ml of distilled water into 35ml of absolute ethanol, stir at 400rpm for 10min and add hydrochloric acid to adjust the pH value of the solution to 2. The above solution was slowly dropped into the diatomite slurry under stirring, and the dropwise addition was completed in 10 minutes, and stirred at a speed of 400 rpm for 30 minutes and ultrasonically oscillated for 1 hour. Stand still in a water bath at 50°C for 24 hours. After the material forms a gel and cannot flow, it is vacuum-dried at 60°C for 3 hours, and calcined in a muffle furnace at 450°C for 2 hours to obtain titanium-loaded diatomite. ...

Embodiment 3

[0063] According to the method in Example 1, the original diatom earth was subjected to expansion treatment to obtain diatom concentrate with a high specific surface area.

[0064] Mix 35ml of absolute ethanol with 10ml of butyl titanate, stir at 200rpm for 10 minutes, then add 20g of diatomite, and stir vigorously for 10 minutes to form a slurry. Add 4ml of glacial acetic acid and 10ml of distilled water into 25ml of absolute ethanol, stir at a speed of 400rpm for 10min, and add hydrochloric acid to adjust the pH value of the solution to 2. The above solution was slowly dropped into the diatomite slurry under stirring, and the dropwise addition was completed in 10 minutes, stirred at a speed of 400 rpm for 30 minutes and ultrasonically oscillated for 30 minutes. Stand in a water bath at 50°C for 24 hours, and after the material forms a gel and cannot flow, dry it in vacuum at 60°C for 2 hours, and roast it in a muffle furnace at 480°C for 2 hours to obtain titanium-loaded dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com