Preparation and regeneration method of algal toxin degrading bacterium protoplast

A technology of protoplasts and degrading bacteria, applied in biochemical equipment and methods, bacteria, microorganisms, etc., can solve the problems of single population structure and low degradation efficiency, and achieve simple operation, low equipment requirements, enzymatic hydrolysis time and regeneration cycle. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

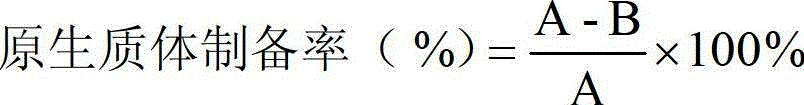

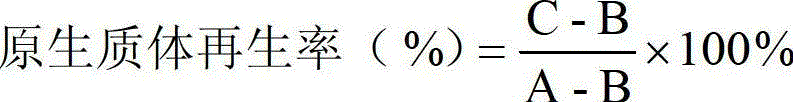

Image

Examples

Embodiment 1

[0041] Pick a ring of bacteria from the slant medium of the preserved strain R3 (Lysinibacillus fusiformis) and put it into a conical flask filled with 30mL of fresh bacterial liquid medium, in a shaking incubator at a temperature of 28°C and a speed of 130r / min After activating and culturing for 15 hours, the seed culture solution of R3 was obtained. Take 4mL and centrifuge at 4300r / min for 12min; add 4mL of SMM buffer to the precipitated cells, centrifuge and wash mycelium 3 times; resuspend with 1.8mL of SMM buffer to obtain R3 mycelia suspension. Add 0.2 mL of lysozyme with a concentration of 10 mg / mL and 2 mL of EDTA solution with a concentration of 0.8 mg / mL heated to 32 °C, and perform enzymatic hydrolysis at 32 °C for 1 h in a water bath to obtain an enzymatic hydrolysis solution of R3. Centrifuge at a speed of 3200r / min for 8min, add 4mL of NaCl solution with a concentration of 0.55mol / L to the precipitated protoplasts, wash by centrifugation for 3 times, and suspend ...

Embodiment 2

[0043] Pick a ring of bacteria from the slant medium of the preserved strain R3 (Lysinibacillus fusiformis) and put it into a conical flask filled with 30mL of fresh bacterial liquid medium, in a shaking incubator at a temperature of 28°C and a speed of 130r / min After activating and culturing for 12 hours, the seed culture solution of R3 was obtained. Take 4mL and centrifuge at 4300r / min for 12min; add 4mL of SMM buffer to the precipitated bacteria, centrifuge and wash mycelium 3 times; resuspend with 1.6mL of SMM buffer to obtain R3 mycelia suspension. Add 0.4 mL of lysozyme with a concentration of 10 mg / mL and 2 mL of EDTA solution with a concentration of 0.8 mg / mL heated to 32 °C, and perform enzymatic hydrolysis at 32 °C for 1 h in a water bath to obtain an enzymatic hydrolysis solution of R3. Centrifuge at a speed of 3200r / min for 8min, add 4mL of NaCl solution with a concentration of 0.55mol / L to the precipitated protoplasts, wash by centrifugation for 3 times, and suspe...

Embodiment 3

[0045] Pick a ring of bacteria from the slant medium of the preserved strain R3 (Lysinibacillus fusiformis) and put it into a conical flask filled with 30mL of fresh bacterial liquid medium, in a shaking incubator at a temperature of 28°C and a speed of 130r / min After activating and culturing for 12 hours, the seed culture solution of R3 was obtained. Take 4mL and centrifuge at 4300r / min for 12min; add 4mL of SMM buffer to the precipitated cells, centrifuge and wash mycelium 3 times; resuspend with 1.8mL of SMM buffer to obtain R3 mycelia suspension. Add 0.2 mL of lysozyme with a concentration of 10 mg / mL and 2 mL of EDTA solution with a concentration of 0.8 mg / mL heated to 32 °C, and perform enzymatic hydrolysis at 32 °C for 1 h in a water bath to obtain an enzymatic hydrolysis solution of R3. Centrifuge at a speed of 3200r / min for 8min, add 4mL of NaCl solution with a concentration of 0.55mol / L to the precipitated protoplasts, wash by centrifugation for 3 times, and suspend ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com