Polydimethyldiallylammonium chloride modified color fixing agent and preparation method thereof

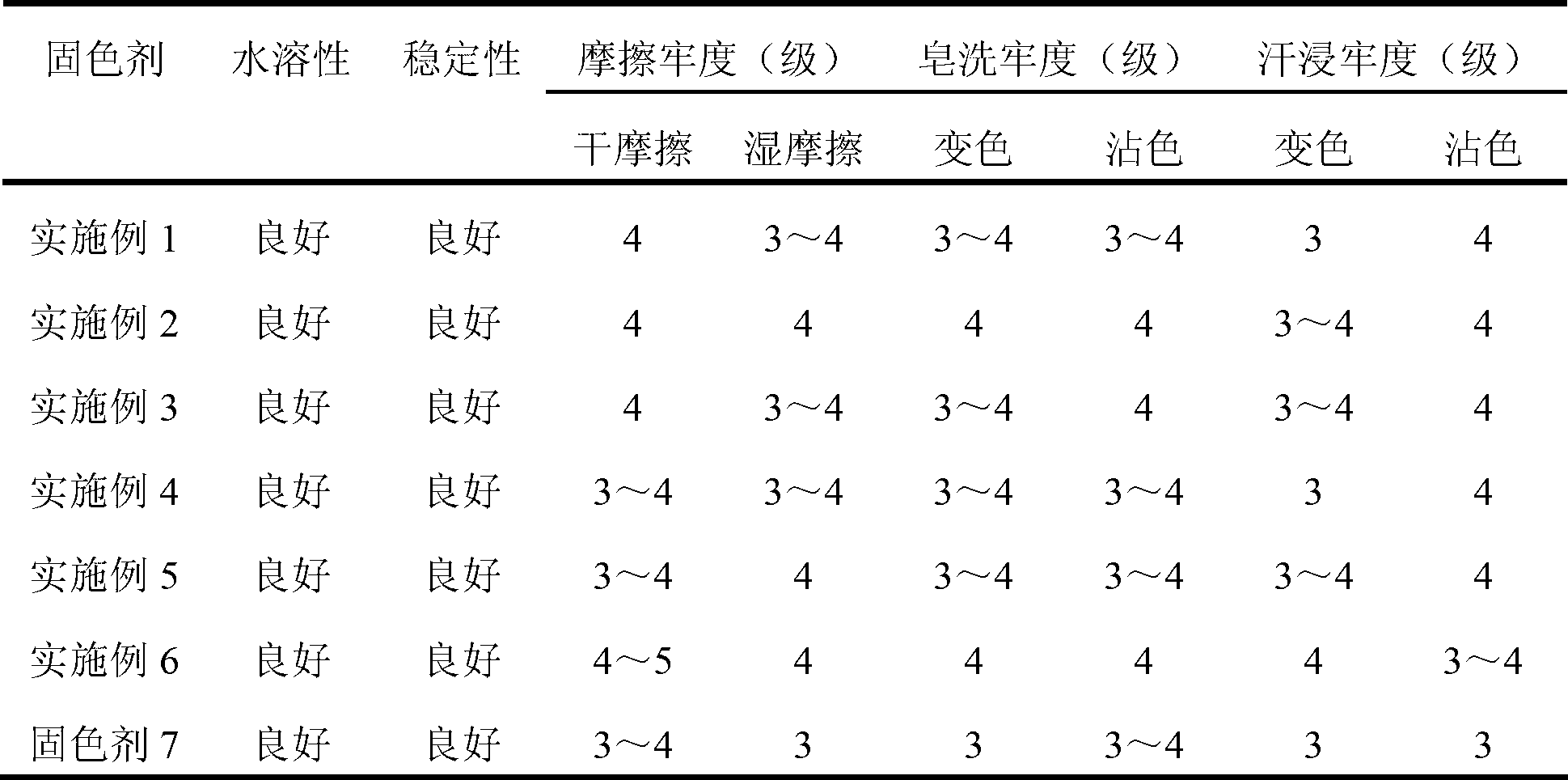

A technology of polydimethyldiallyl ammonium chloride and dimethyldiallyl ammonium chloride, applied in the field of polydimethyldiallylammonium chloride modified color-fixing agent and its preparation, It can solve the problems of low wet rubbing fastness of dyed fabrics, poor wet rubbing fastness and color fastness to washing, and low color fixation rate of reactive dyes, so as to improve dry rubbing fastness, improve quality, and improve wet and dry fastness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

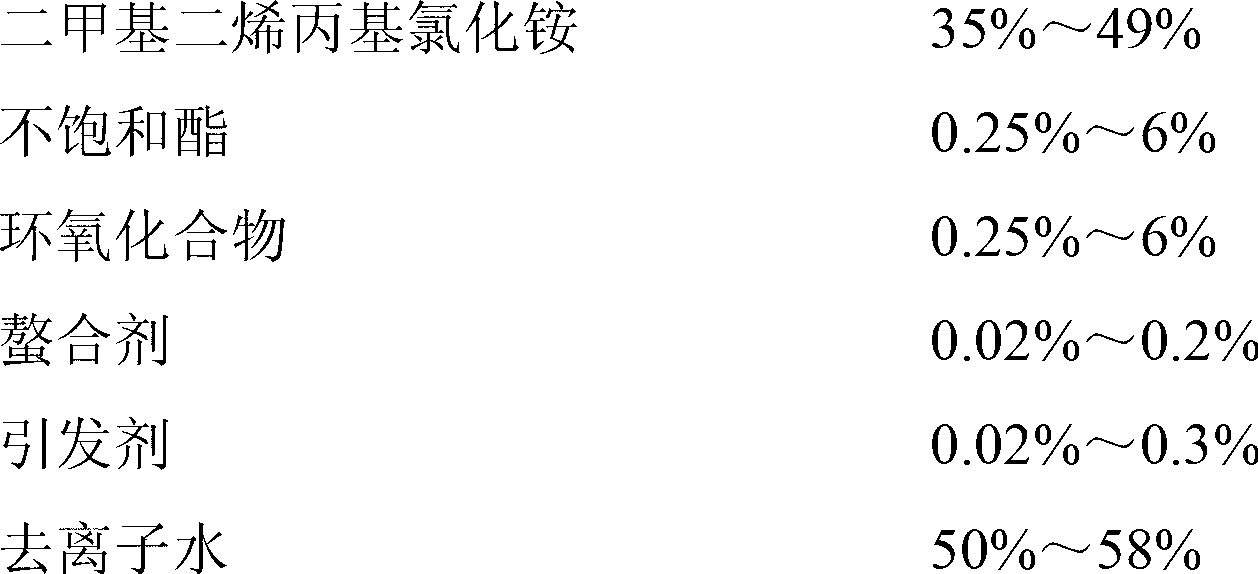

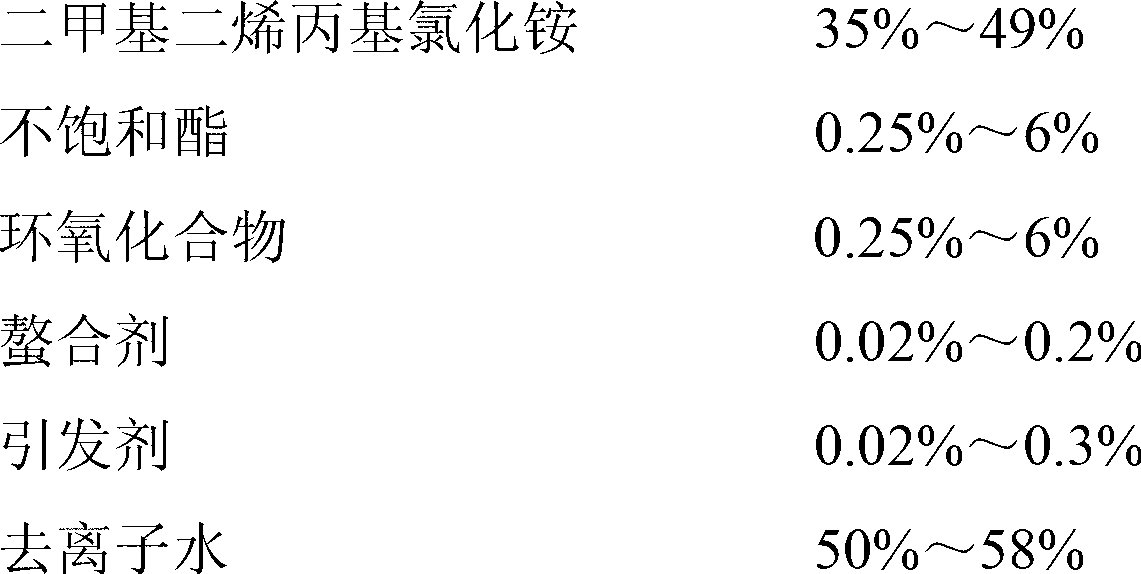

[0039] A polydimethyldiallylammonium chloride modified color fixing agent of the present invention is made of the following raw material components in mass fraction ratio:

[0040] Dimethyl diallyl ammonium chloride: 350 kg

[0041] Methyl acrylate: 40 kg

[0042] Allyl glycidyl ether: 49 kg

[0043] Disodium edetate: 0.2 kg

[0044] Ammonium persulfate: 0.8 kg

[0045] Deionized water: 560 kg

[0046] Wherein, dimethyl diallyl ammonium chloride is an aqueous solution with a concentration of about 60% by mass.

[0047] A kind of preparation method of polydimethyldiallyl ammonium chloride modified color fixing agent of the present invention, realize through following steps:

[0048] (1) Add 0.2 kg of the disodium edetate and 2 kg of the deionized water into the reaction kettle to prepare a disodium edetate solution, start stirring, and start to heat up.

[0049] (2) When the temperature rises to 60°C, add it dropwise from four high-level tanks at the same time. The first ...

Embodiment 2

[0052] A polydimethyldiallylammonium chloride modified color fixing agent of the present invention is made of the following raw material components in mass fraction ratio:

[0053] Dimethyl diallyl ammonium chloride: 400 kg

[0054] Ethyl acrylate: 10 kg

[0055] Allyl polyoxyethylene epoxy ether: 49 kg

[0056] Tetrasodium EDTA: 0.4 kg

[0057] Ammonium persulfate: 0.6 kg

[0058] Deionized water: 540 kg.

[0059] Wherein, dimethyl diallyl ammonium chloride is an aqueous solution with a concentration of about 60% by mass.

[0060] A kind of preparation method of polydimethyldiallyl ammonium chloride modified color fixing agent of the present invention, realize through following steps:

[0061] (1) Add 0.4 kg of tetrasodium edetate and 2 kg of deionized water into the reaction kettle to prepare a tetrasodium edetate solution, start stirring, and start heating to raise the temperature.

[0062] (2) When the temperature rises to 65°C, add it dropwise from four high-level t...

Embodiment 3

[0065] A polydimethyldiallylammonium chloride modified color fixing agent of the present invention is made of the following raw material components in mass fraction ratio:

[0066] Dimethyl diallyl ammonium chloride: 450 kg

[0067] Methyl methacrylate: 10 kg

[0068] Glycidyl methacrylate: 19 kg

[0069] Sodium gluconate: 0.5 kg

[0070] Potassium persulfate: 0.5 kg

[0071] Deionized water: 520 kg

[0072] Wherein, dimethyl diallyl ammonium chloride is an aqueous solution with a concentration of about 60% by mass.

[0073] A kind of preparation method of polydimethyldiallyl ammonium chloride modified color fixing agent of the present invention, realize through following steps:

[0074] (1) Add 0.5 kg of the above-mentioned sodium gluconate and 2 kg of the above-mentioned deionized water into the reaction kettle to prepare a sodium gluconate solution, start stirring, and start heating to raise the temperature.

[0075] (2) When the temperature rises to 75°C, add it drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com