Flexible substrate

一种柔性衬底、同一的技术,应用在有机光电领域,能够解决柔性衬底不能切割、生产成本高等问题,达到制备精度要求低、降低生产成本、简化工艺步骤的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

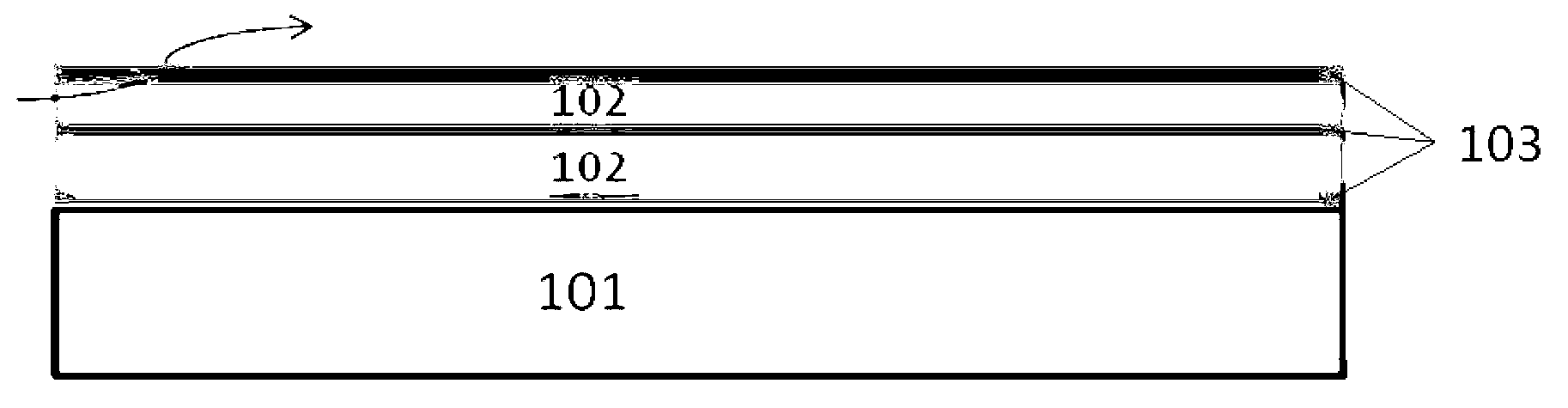

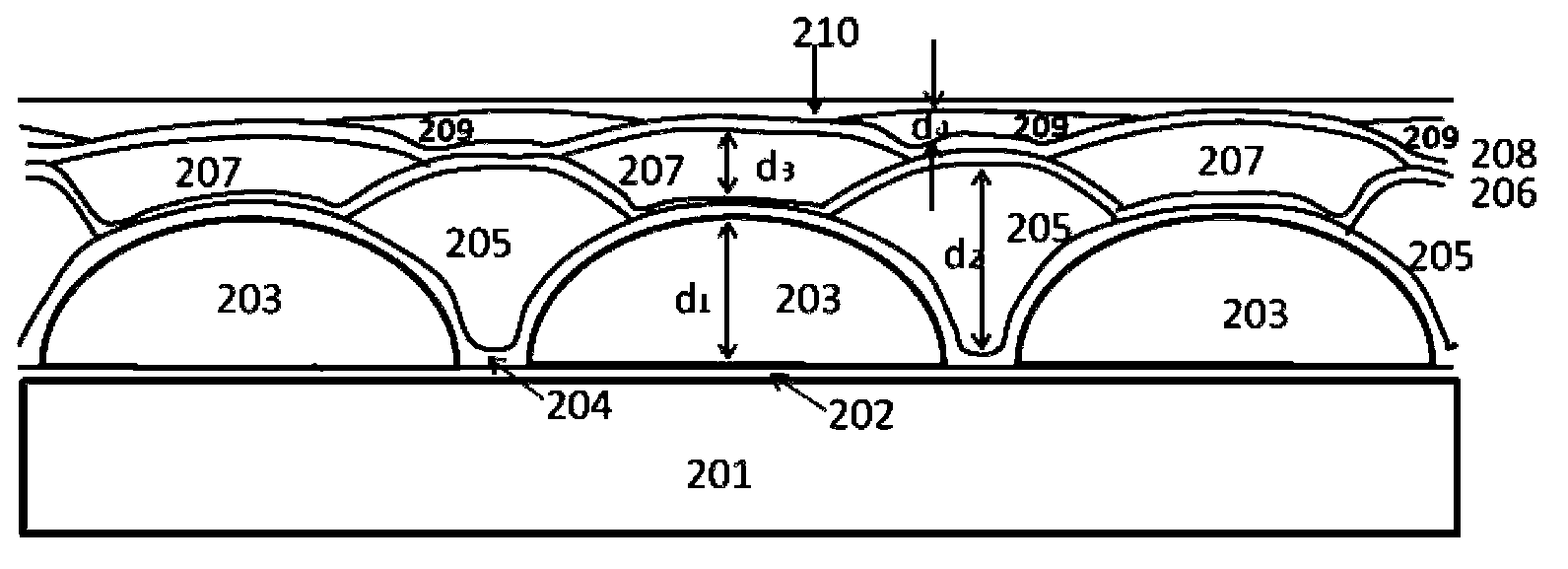

[0042] as attached Figure 2-3 As shown, a flexible substrate provided in this embodiment includes a PI substrate 201, a first barrier layer 202, a first planarization layer 203, a second barrier layer 204, a second The planarization layer 205 , the third barrier layer 206 , the third planarization layer 207 , the fourth barrier layer 208 , the fourth planarization layer 209 , and the fifth barrier layer 210 .

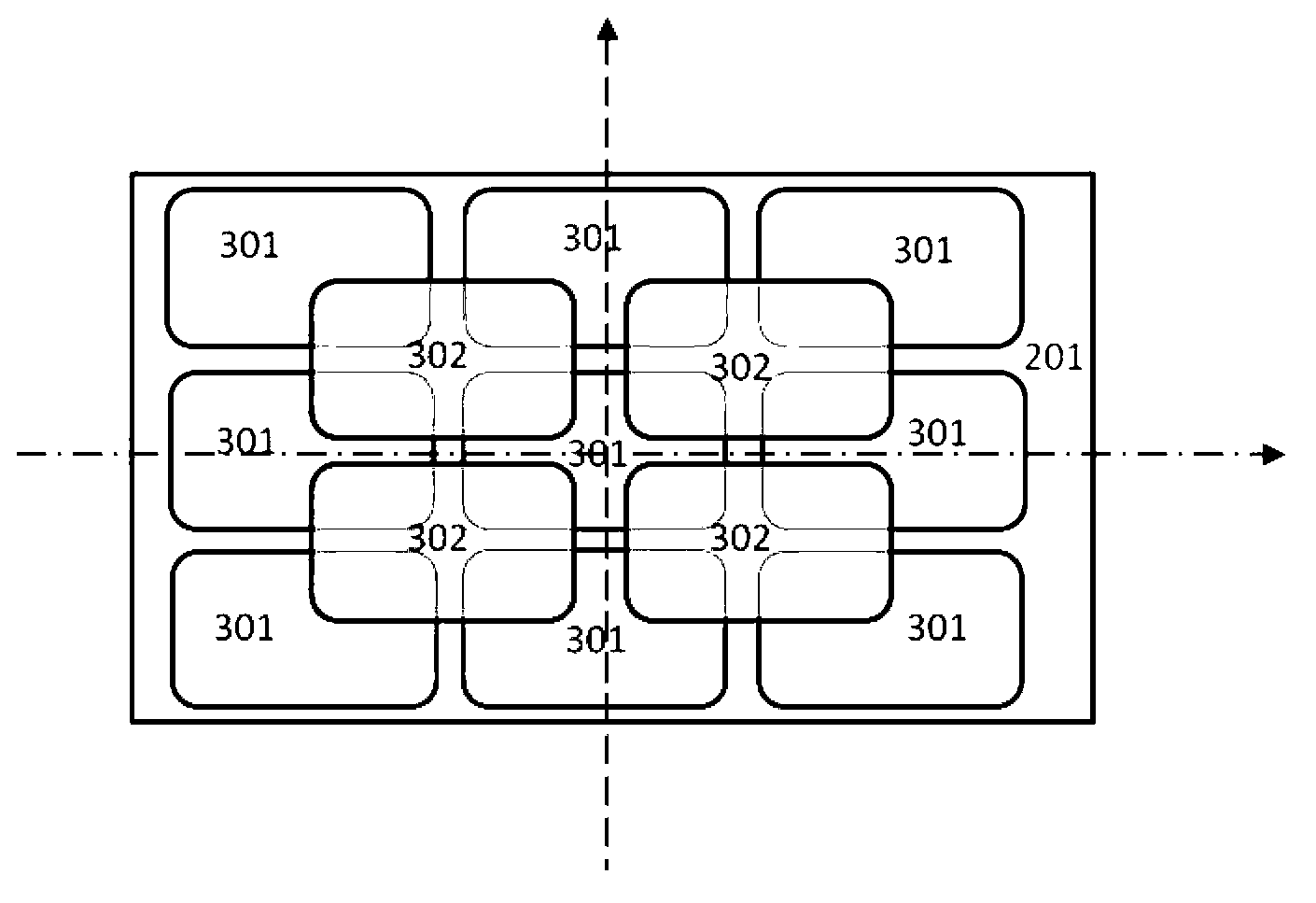

[0043] The first planarization layer 203, the second planarization layer 205, the third planarization layer 207, and the fourth planarization layer 209 are all composed of planarization units separated from each other and arranged periodically in the first direction and the second direction , the first direction and the second direction are as image 3 As shown in the direction of the middle arrow, the included angle is 90°. The patterns of the planarization units are the same, and the projections on the PI substrate 201 are all rectangles of the same size, the length ...

Embodiment 2

[0052] A flexible substrate structure provided in this embodiment is as figure 2 As shown, the preparation method is the same as in Example 1, the only difference is that the patterns of the planarization units in the first planarization layer 203, the second planarization layer 205, the third planarization layer 207, and the fourth planarization layer 209 Different from Example 1, such as Figure 4 As shown, the planarization units in the first planarization layer 203 and the third layer 207 are circles with equal radii, and the projections on the PI substrate 201 coincide, and the radius of the circles is 800 μm. The thickness of the first planarization layer is 2 μm, the thickness of the third planarization layer is 0.5 μm, and the distance between adjacent circles in the first direction and the second direction is equal, both are 200 μm; the second planarization layer 205 and The planarization unit in the fourth planarization layer 209 is a circle with a radius of 500 μm...

Embodiment 3

[0054] A flexible substrate structure provided in this embodiment is as figure 2 As shown, the preparation method is the same as that in Example 2, the only difference is that the arrangement of the planarization units in the first planarization layer 203, the second planarization layer 205, the third planarization layer 207, and the fourth planarization layer 209 The cloth method is different from Examples 1 and 2. In Embodiments 1 and 2, the planarization layer units are periodically arranged in the first direction and the second direction, and the angle between the two directions is 90°; and in this embodiment, as Figure 5 As shown, the planarization units are periodically arranged in the first direction and the second direction, and the angle between the two directions is 60°.

[0055] The planarization units in the first planarization layer 203 and the third layer 207 are circles with equal radii, the projections of 203 and 207 on the PI substrate 201 coincide, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com