Preparation method for positive electrode material of power lithium ion battery

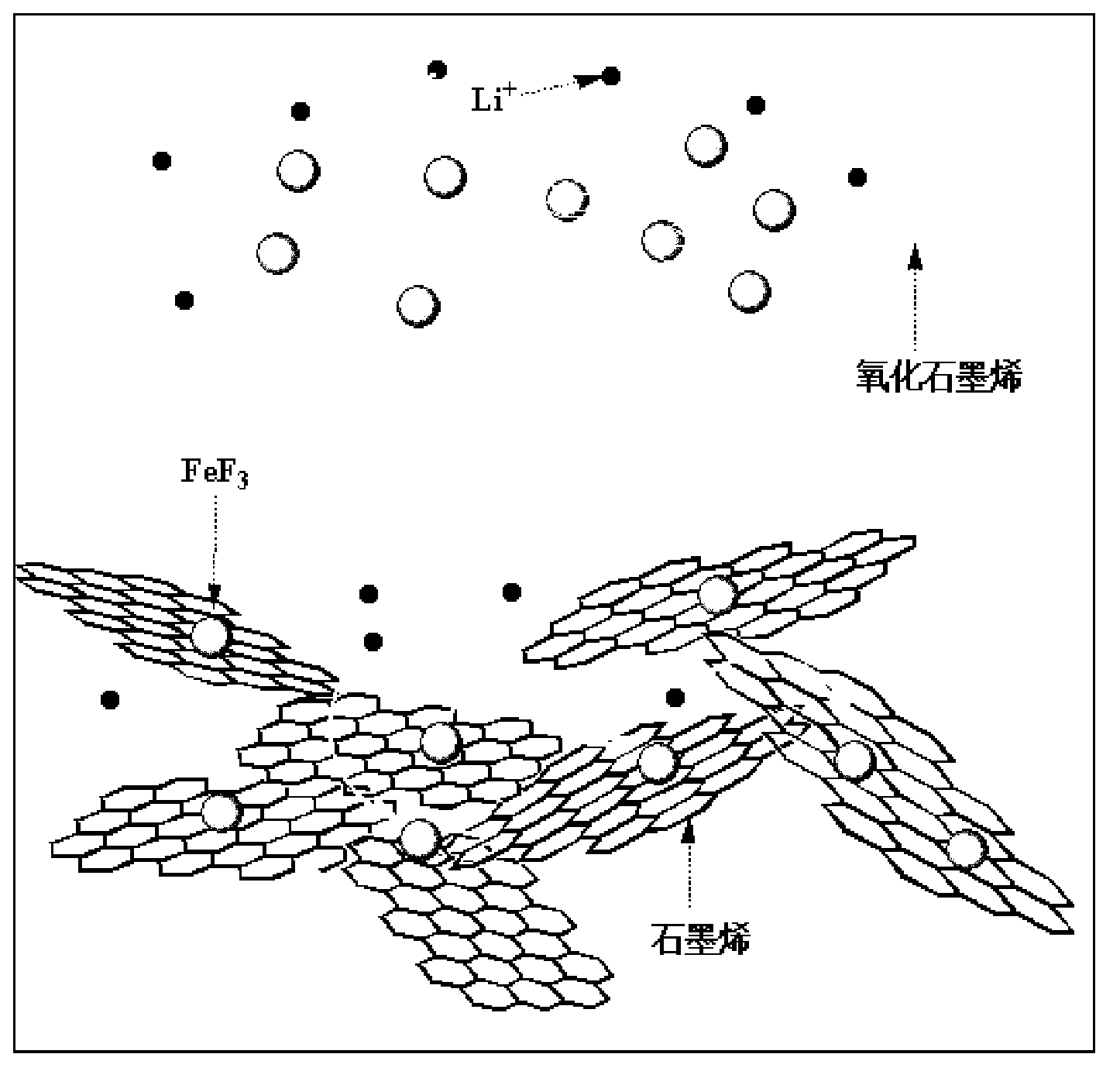

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reduced battery efficiency and cycle performance, capacity attenuation, poor conductivity, etc., to achieve excellent electrical performance, improve efficiency, and super The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Preparation of graphite oxide:

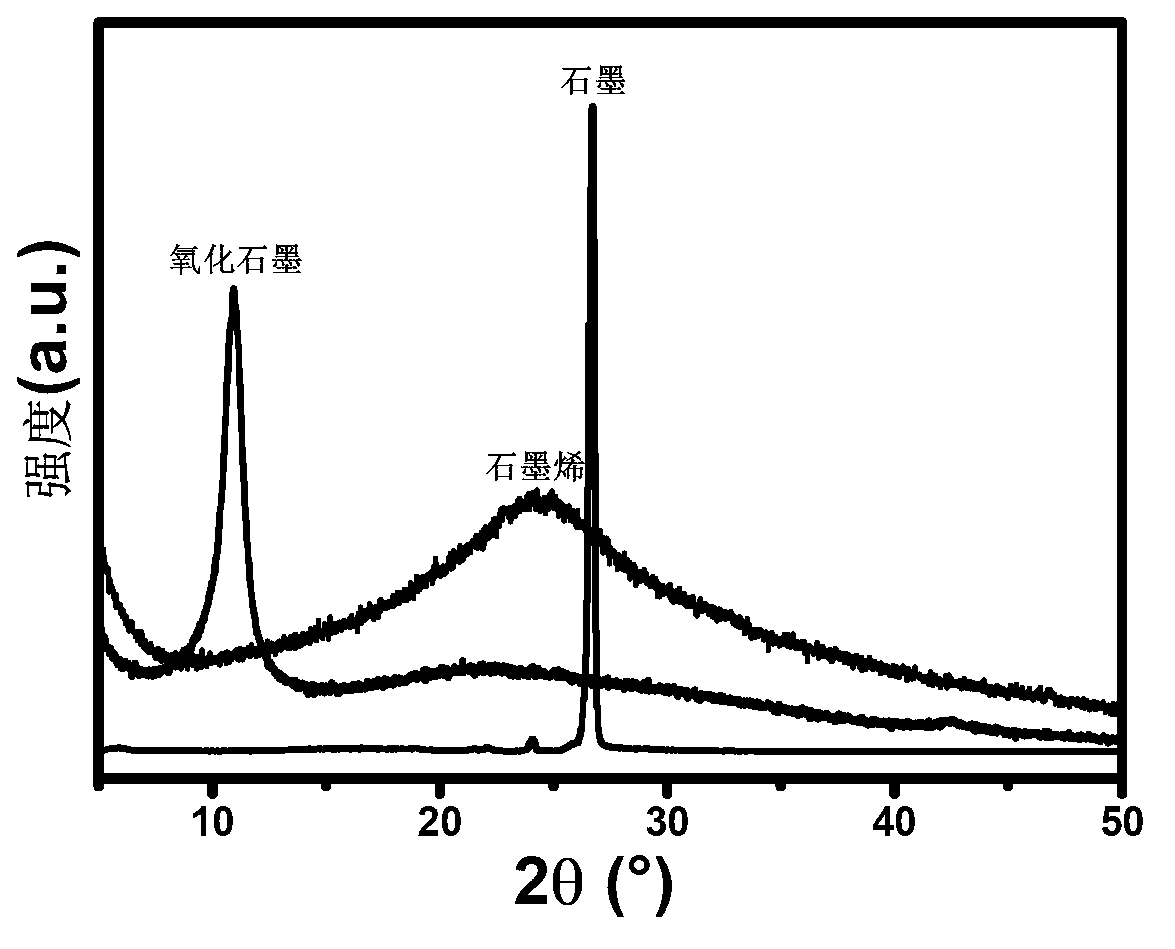

[0030] Take 1g (8000 mesh) of natural flake graphite and 47ml of sulfuric acid with a mass concentration of 98% and mix evenly, then add 1.7g of potassium nitrate, quickly add 5.2g of potassium permanganate in a water bath at 7°C, mix well, and then add potassium permanganate The process maintains the system temperature at 0-20°C. Then raise the temperature of the system to 50°C, react for 1.5h, then add 70ml of water, and at the same time raise the temperature of the system to 90°C for 13min, then add 160ml of distilled water to terminate the reaction, centrifugally wash until the pH is 6, and vacuum dry at 70°C to obtain graphite oxide solid. XRD characterization as image 3 , the interlayer distance of graphite oxide is 0.863nm, which is greatly increased compared with the interlayer distance of 0.34nm of initial graphite, indicating that the effect of intercalation graphite oxide is very good.

[0031] 2) FeF 3 Preparation of ...

Embodiment 2

[0039] 1) Preparation of graphite oxide:

[0040] Take 1g (8000 mesh) of natural flake graphite and 56ml of sulfuric acid with a mass concentration of 92% and mix evenly, then add 1.2g of potassium nitrate, quickly add 5.8g of potassium permanganate in a water bath at 11°C, mix well, and then add potassium permanganate The process maintains the system temperature at 0-20°C. Then raise the temperature of the system to 50°C, react for 2 hours, then add 60ml of water, and at the same time raise the temperature of the system to 75°C for 25 minutes, then add 200ml of distilled water to terminate the reaction, centrifugally wash until the pH is 5, and vacuum dry at 65°C to obtain solid graphite oxide . Consistent with the characterization results of Example 1, the interlayer distance of graphite oxide is 0.85nm, which is significantly increased compared with the initial graphite, indicating that the oxidation effect of graphite oxide is very good.

[0041] 2) FeF 3 Preparation of...

Embodiment 3

[0048]1) Preparation of graphite oxide:

[0049] Take 1g (8000 mesh) of natural flake graphite and 43ml of sulfuric acid with a mass concentration of 96% and mix evenly, then add 2g of potassium nitrate, quickly add 6g of potassium permanganate in a water bath at 10°C, mix well, and add potassium permanganate Keep the system temperature at 0-20°C. Then raise the temperature of the system to 45°C, react for 3 hours, then add 60ml of water, and at the same time raise the temperature of the system to 85°C for 20 minutes, then add 120ml of distilled water to terminate the reaction, centrifugally wash until the pH is 7, and vacuum dry at 50°C to obtain solid graphite oxide . Consistent with the characterization results of Example 1, the interlayer distance of graphite oxide is 0.845nm, which is significantly increased compared with the initial graphite, indicating that the oxidation effect of graphite oxide is very good.

[0050] 2) FeF 3 Preparation of nanoparticles:

[0051] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com