Miniature composite structure laser

A composite structure and laser technology, applied in the field of micro-optical components, can solve problems such as unfavorable optical integration, general structural quality factor, complex processing technology, etc., and achieve the effect of simple preparation, high quality factor and low threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation process of the micro composite structure laser of the present invention is as follows:

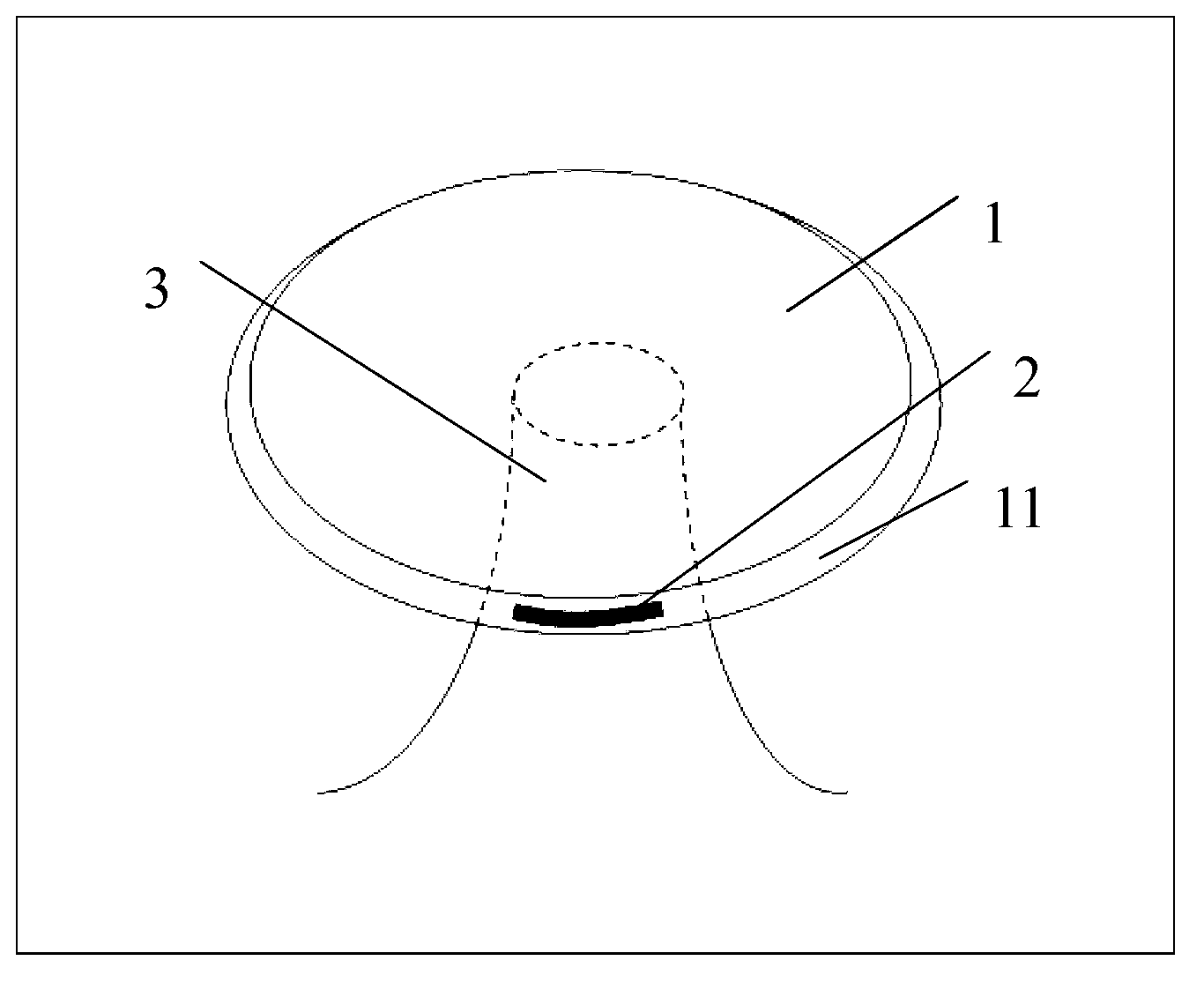

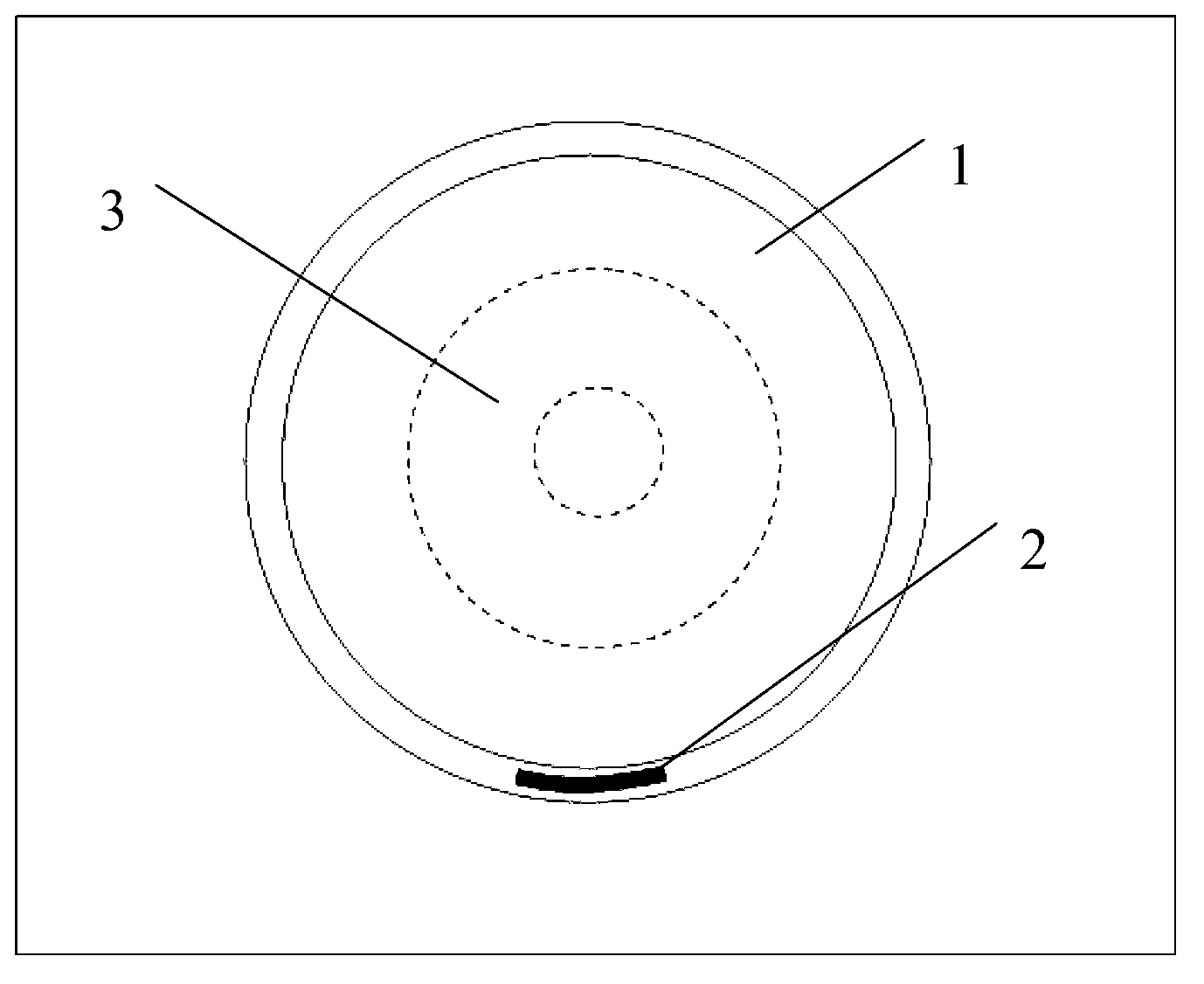

[0025] (1), with the combination of photolithographic mask, dry etching and wet etching means, a whispering gallery type silicon oxide microdisk 1 is prepared on a silicon wafer growing a silicon oxide film, and the silicon oxide microdisk 1 is a resonant cavity, wherein , a slope 11 is provided on the side of the silicon oxide microdisk 1 . Silicon oxide microdisk 1 resonators with different diameters and thicknesses can be obtained by controlling the mask process and selecting different thicknesses of the silicon oxide film. The diameter of the silicon oxide microdisk 1 is 20-100 μm, and the thickness of the silicon oxide microdisk 1 is 0.2-2 μm. Wherein, the silicon oxide microdisk 1 is supported by silicon pillars 3 formed by etching;

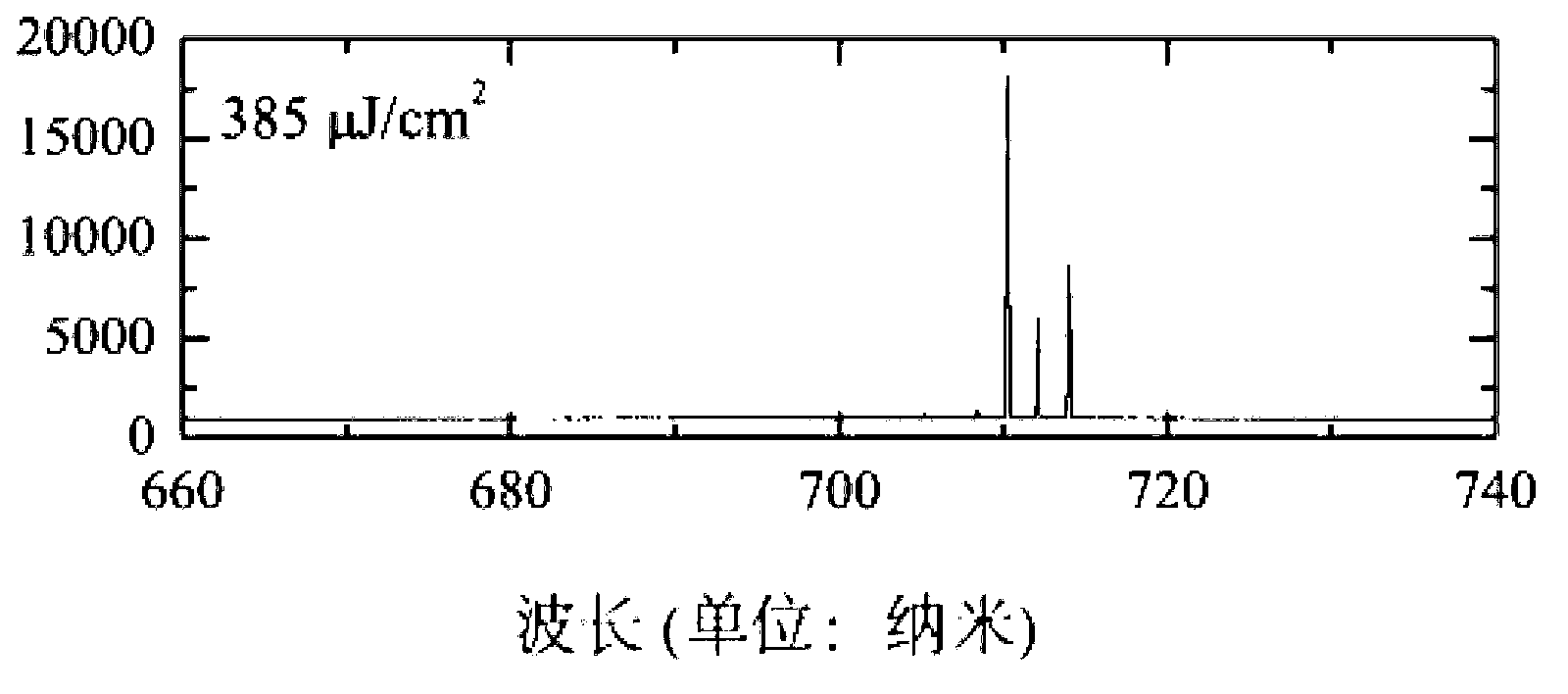

[0026] (2), the semiconductor nanowire 2 is grown in a tubular high-temperature furnace by physical vapor deposition, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com