Precoated sand composition and preparation method thereof

A technology of composition and coated sand, which is applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of large energy consumption, long curing time, and incomplete curing of coated sand, so as to improve production efficiency, The effect of reducing energy consumption and fast curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a kind of preparation method of coated sand composition, and this method comprises the following steps:

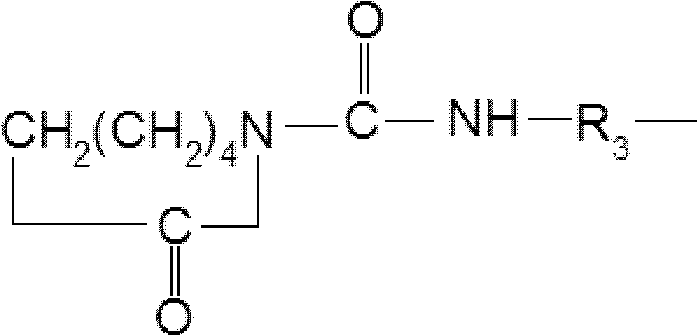

[0040] (1) under the synthetic condition of phenolic resin, formaldehyde, phenol and modified component are mixed contact, obtain modified phenolic resin, and described modified component is the reaction product of caprolactam and isocyanate and / or resorcinol, The isocyanate is aliphatic isocyanate and / or aromatic isocyanate;

[0041] (2) Silica sand and the modified phenolic resin are mixed, and then cured.

[0042] Preferably, the modified component in step (1) is a reaction product of caprolactam and isocyanate, or a mixture of a reaction product of caprolactam and isocyanate and resorcinol. In this case, the conditions for the reaction of caprolactam and isocyanate preferably include: a reaction temperature of 50-110°C, more preferably 70-100°C; a reaction time of 1-20 hours, more preferably 5-10 hours; caprolactam and isocya...

Embodiment 1

[0057] This example is used to illustrate the coated sand composition and its preparation method of the present invention.

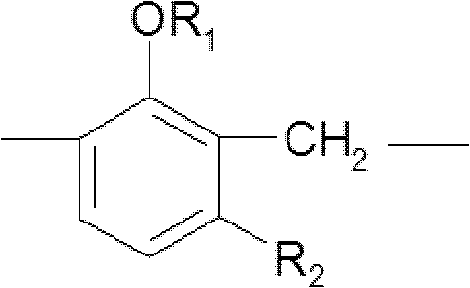

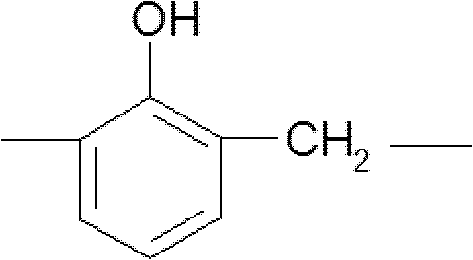

[0058] (1) Preparation of modified phenolic resin

[0059] 5.65 g (0.05 mol) of caprolactam and 9.86 g (0.05 mol) of o-toluene isocyanate were reacted at 90° C. for 10 hours. Then, the reaction product obtained, 94g (1mol) of phenol, 21g (0.7mol) of formaldehyde and 1g of oxalic acid were added to the reactor, heated to 100°C with stirring, and reacted at this temperature for 5 hours to obtain the modified Reactive phenolic resin. Detect the weight-average molecular weight of this modified phenolic resin according to gel permeation chromatography, and in conjunction with the nuclear magnetic resonance spectrum data of this modified phenolic resin can calculate, the average degree of polymerization of this modified phenolic resin is about 6, and the modified phenolic resin The content of the repeating unit represented by the above formula (I) in the phe...

Embodiment 2

[0071] This example is used to illustrate the coated sand composition and its preparation method of the present invention.

[0072] Prepare modified phenolic resin and coated sand according to the method of embodiment 1, difference is, in step (1), replace the reaction product of caprolactam and o-toluene isocyanate with the resorcinol of 15.5g, thereby prepare The resulting sheet sand-based product A2 had a degree of cure of about 79%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com