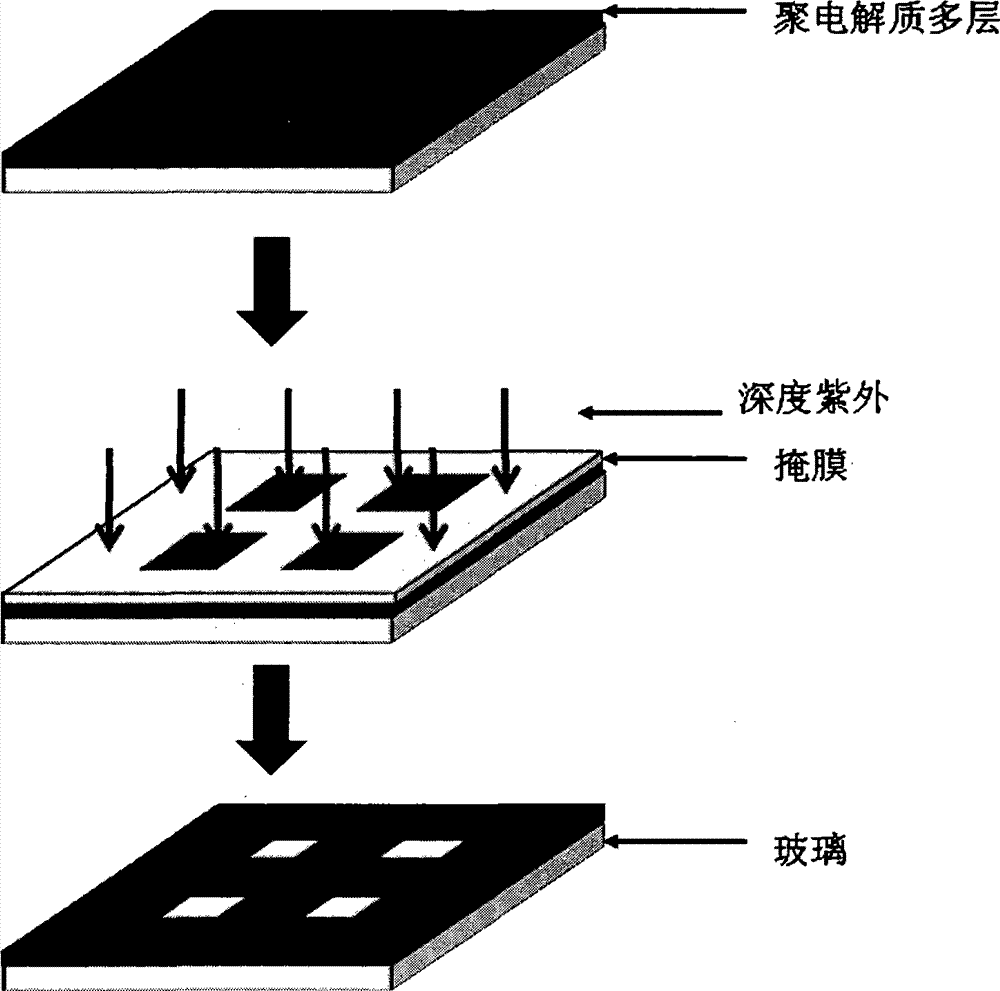

Phospholipid bilayer membrane array fabricated by multilayer polyelectrolyte membrane substrate and fabrication method

A polyelectrolyte, double-layer membrane technology, applied in the field of membrane biophysics, can solve the problems of expensive instruments, high technical level requirements, and many control factors, and achieve the effects of low cost, good controllability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Preparation of APTES self-assembled monolayer film: ultrasonically clean the glass substrate with absolute ethanol and distilled water for 5 minutes, blow dry with nitrogen and place it in a plasma cleaner for 20 seconds; put the cleaned substrate into 3-ammonia Self-assemble in a mixed solution of propyltriethoxysilane (APTES) and toluene for 2 hours, and its volume ratio is 1:50. After the assembly is completed, it is cleaned with toluene and dried with nitrogen gas for use;

[0019] (2), layer-by-layer assembly of polyelectrolytes: poly(4-styrene sulfonate sodium) (PSS) and poly(diallyldimethylammonium chloride) (PDDA) were formulated to a concentration of 2 mg / mL Add NaCl to the aqueous solution to make the NaCl concentration 0.5mol / L, and adjust the pH to 1.0 for use; soak the substrate modified with 3-aminopropyltriethoxysilane (APTES) in the prepared Poly(4-styrene sulfonate sodium) (PSS) solution for 10min, take it out, rinse it with distilled water and dry ...

Embodiment 2

[0024] (1) Preparation of APTES self-assembled monolayer film: ultrasonically clean the glass substrate with absolute ethanol and distilled water for 10 minutes, blow dry with nitrogen and place it in a plasma cleaner for 30 seconds; put the cleaned substrate into 3-ammonia Self-assemble in a mixed solution of propyltriethoxysilane (APTES) and toluene for 4 hours, its volume ratio is 1:150, after the assembly is completed, it is cleaned with toluene and dried with nitrogen gas for use;

[0025] (2), layer-by-layer assembly of polyelectrolytes: poly(4-styrene sulfonate sodium) (PSS) and poly(diallyldimethylammonium chloride) (PDDA) were formulated to a concentration of 2 mg / mL Add NaCl to the aqueous solution to make the NaCl concentration 0.5mol / L, and adjust the pH to 3.0 for use; soak the substrate modified with 3-aminopropyltriethoxysilane (APTES) in the prepared In the poly(4-styrene sodium sulfonate) (PSS) solution for 20min, take it out, rinse it with distilled water and...

Embodiment 3

[0030] (1) Preparation of APTES self-assembled monolayer film: ultrasonically clean the glass substrate with absolute ethanol and distilled water for 10 minutes, blow dry with nitrogen and place it in a plasma cleaner for 30 seconds; put the cleaned substrate into 3-ammonia Self-assemble in a mixed solution of propyltriethoxysilane (APTES) and toluene for 4 hours, and its volume ratio is 1:150. After the assembly is completed, it is cleaned with toluene and dried with nitrogen gas for use;

[0031] (2), layer-by-layer assembly of polyelectrolytes: poly(4-styrene sulfonate sodium) (PSS) and poly(diallyl dimethyl ammonium chloride) (PDDA) were respectively prepared into 2 mg / mL Add NaCl to the aqueous solution to make the NaCl concentration 0.5mol / L, and adjust the pH to 3.0 for use; soak the substrate modified with 3-aminopropyltriethoxysilane (APTES) in the prepared In the poly(4-styrene sulfonate sodium) (PSS) solution for 20min, take it out, rinse it with distilled water and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com