Controlled availability special BB fertilizer for cotton and preparation thereof

A cotton, long-acting technology, applied in the field of long-acting special fertilizer for cotton, can solve the problems of complex coating process, expensive production materials and high product cost, and achieve the maintenance of soil structure, smooth and lasting supply and release, and long fertilizer effect period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

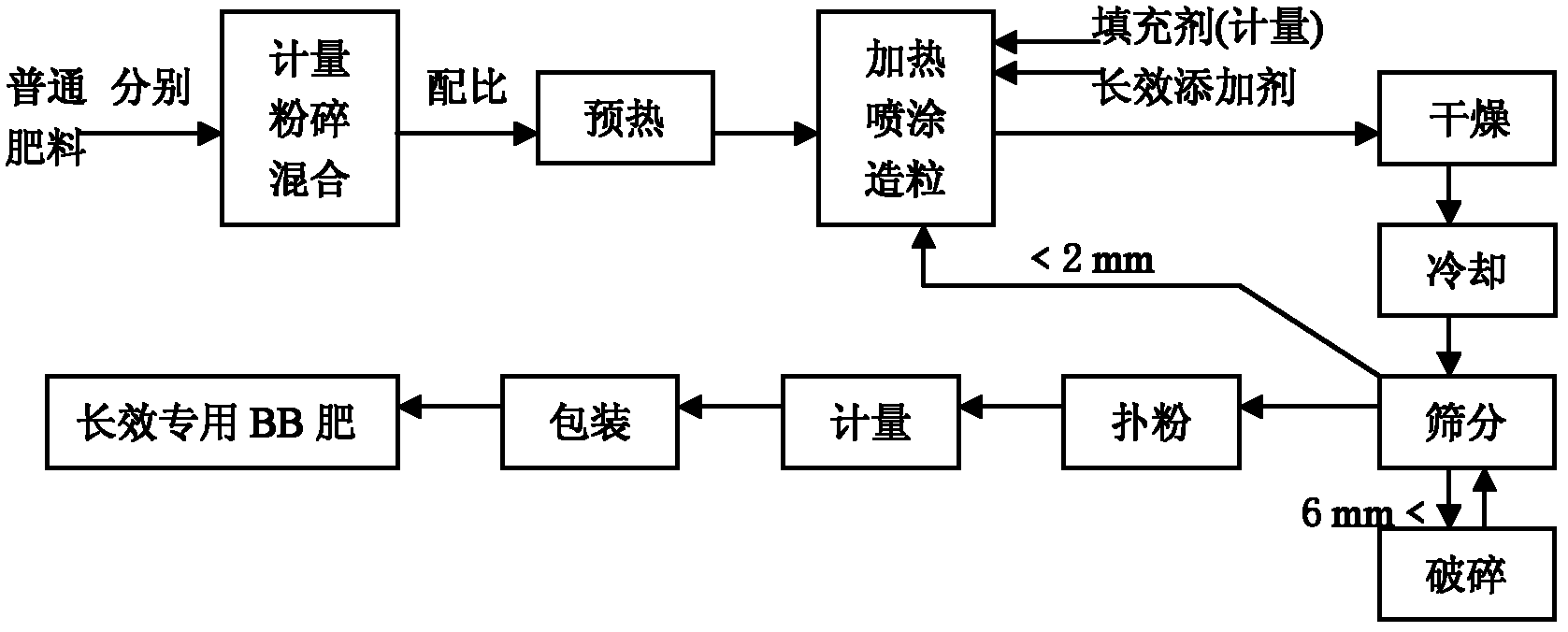

Method used

Image

Examples

Embodiment 1

[0022] Weigh basic fertilizers urea, monoammonium phosphate, superphosphate, potassium sulfate and a small amount of trace element fertilizers, nitrogen, phosphorus, potassium fertilizers and trace elements are based on effective content, and the weight fraction is 25 parts N, 12 parts P 2 o 5 , 3 copies of K 2 O, 0.57 parts of trace element iron, 0.44 parts of zinc, and 0.3 parts of manganese are blended in a proportional relationship. The pure nutrients of the above fertilizers account for not less than 40% of the total weight percentage of BB fertilizers. In addition, nitrogen inhibitor nitrogen-pyridine is added to account for the weight of BB fertilizers. 1.2% of the total weight, oxalic acid weight accounted for 4% of the total weight of BB fertilizer.

[0023] Mix the nitrogen, phosphorus, potassium fertilizer, trace elements and bentonite in the BB fertilizer in the above proportions and crush them through a 40-mesh sieve. Mix the sieved fertilizer with nitrogen inhib...

Embodiment 2

[0027] Nitrogen, phosphorus, and potassium fertilizers are based on effective content and blended by weight fraction, that is, N:P 2 o 5 : K 2 O=23:12:5, the content of trace elements is 2.4%, and the total nutrient content accounts for no less than 42% of the total weight of the BB fertilizer. Above-mentioned nitrogen, phosphorus, potassium fertilizer and trace element are respectively: take by weighing 40 kilograms of urea (N 46%), monoammonium phosphate (N 12%, P 2 o 5 59%) 8 kg, heavy superphosphate (P 2 o 5 46%) 11.7 kg, potassium sulfate (K 2 (2050%) 8.4 kilograms, in addition take by weighing 2 kilograms of zinc sulfate heptahydrate, 1 kilogram of manganese sulfate monohydrate, 3 kilograms of ferrous sulfate heptahydrate, then mix with 15.2 kilograms of fly ash, sieve after pulverizing, then add and 2.4 kg of dicyandiamide (DCD) and 4 kg of citric acid monohydrate are stirred evenly and added to the drum granulator, and the machine is started to rotate continuou...

Embodiment 3

[0030] Prepare 100kgBB fertilizer: take by weighing 47.9 kilograms of urea (N 46%), monoammonium phosphate (N 12%, P2 o 5 59%) 18.8 kg, potassium sulfate (K 2 O 50%) 7.9 kg, formulated as effective content, N:P by weight fraction 2 o 5 : K 2 O=25:14:5, in addition, weigh 3.0 kg of zinc sulfate heptahydrate, 2.0 kg of manganese sulfate monohydrate, and 4.0 kg of ferrous sulfate heptahydrate. Weigh, pulverize, sieve, add 12.0 kg of bentonite and 5.0 kg of long-acting additive dicyandiamide (DCD), 2.5 kg of citric acid monohydrate and stir evenly, then add to the drum granulator, start the machine to rotate continuously, In the process of adding polyacryl alcohol to prepare a concentration of 2% aqueous solution, the amount of polyacrylamide aqueous solution sprayed is equivalent to about 8% of the total weight of BB fertilizer, so that the outer surface of the particles is evenly attached to the high molecular polymer solution.

[0031] Weigh the above-mentioned cotton long...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com