Lowcost preparation method of MnO2 / graphene composite electrode materials used for supercapacitor

A supercapacitor and graphene composite technology, applied in the manufacture of hybrid/electric double-layer capacitors, etc., can solve the problems of complex process, waste of raw materials, time-consuming and laborious, and achieve the effect of simplifying the process, mild conditions, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

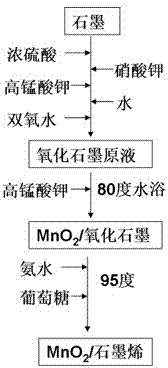

[0018] process such as figure 1 The steps shown are performed:

[0019] a. Add 5g of flake graphite and 120ml of 98% concentrated sulfuric acid into a 1000ml beaker, stir for 10 minutes under ice bath, and then o Under the condition of C, add 2.97g potassium nitrate to the beaker, slowly add 15g potassium permanganate after stirring for 2 hours, stir for 2 hours under ice bath conditions, transfer the beaker to 35 o Continue to stir in the C water bath for 45 minutes, then slowly add 230ml deionized water, and then raise the temperature of the water bath to 98 o C and stir for 30 minutes, remove the beaker from the water bath and add 60 o C deionized water to a volume of 800ml, stirring to bring the temperature down to 25 o C, finally add 5ml mass fraction of 30% H 2 o 2 , stirred for 2 hours to obtain a uniformly dispersed graphite oxide stock solution, namely graphite oxide, Mn 2+ mixed liquid;

[0020] B. get the graphite oxide stoste of 10ml a step gained, measure ...

Embodiment 2

[0028] process such as figure 1 The steps shown are performed:

[0029] a. Add 5g of flake graphite and 120ml of 98% concentrated sulfuric acid into a 1000ml beaker, stir for 10 minutes under ice bath, then o Under the condition of C, add 5g of potassium nitrate to the beaker, slowly add 30g of potassium permanganate after stirring for 3 hours, stir for 3 hours under ice bath conditions, transfer the beaker to 35 o Continue to stir in the C water bath for 60 minutes, then slowly add 300ml deionized water, and raise the temperature of the water bath to 98 o C and stir for 60 minutes, remove the beaker from the water bath and add 60 o C deionized water to a volume of 800ml, stirring to reduce the temperature to 30 o C, finally add 25ml mass fraction of 30% H 2 o 2 , to obtain the graphite oxide stock solution after stirring evenly;

[0030] b. Get the graphite oxide stock solution gained in step a, measure the concentration of divalent manganese ions in the graphite oxide...

Embodiment 3

[0034] process such as figure 1 The steps shown are performed:

[0035] a. Add 5g flake graphite and 120ml 98% concentrated sulfuric acid to a 1000ml beaker, stir for 10 minutes under ice bath, o Under the condition of C, add 2g of potassium nitrate to the beaker, slowly add 22.5g of potassium permanganate after stirring for 2.5 hours, stir for 2.5 hours under ice bath conditions, transfer the beaker to 35 o Continue to stir in the C water bath for 30 minutes, then slowly add 200ml deionized water, and raise the temperature of the water bath to 98 o C and stir for 45 minutes, remove the beaker from the water bath and add 60 o C deionized water to a volume of 700ml, stirring to reduce the temperature to 20 o C, finally add 15ml mass fraction of 30% H 2 o 2 , to obtain the graphite oxide stock solution after stirring evenly;

[0036] b. Get the graphite oxide stock solution gained in step a, measure the concentration of divalent manganese ions in the graphite oxide stock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com