Method for preparing brewing-type ready-to-eat dried tremella by using superheated steam

A technology of superheated steam and tremella drying, which is applied in the field of food processing, can solve the problems of uneven structure, long drying time, and prone to oxidative discoloration, etc., and achieve the effects of scientific and reasonable structure design, uniform internal structure, and remarkable energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

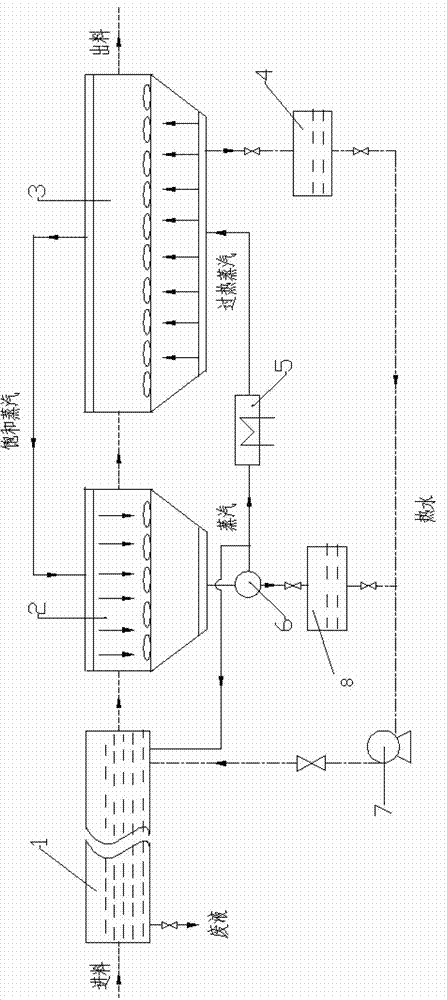

Image

Examples

specific example

[0037]Choose raw white fungus raw materials with dryness <5% moisture, no mildew and plaque. Remove the stalks and impurities of the raw white fungus raw materials, and wash them. The washed white fungus raw materials are put into a soaking chamber for soaking, and the water temperature is 60-90° C. for 6-10 hours. Raw white fungus absorbs water and swells, and the leaves unfold. The raw white fungus after soaking is sent to the cooking chamber, the steam temperature is 90-100°C, and it is cooked for about 1-1.5 hours. The high-temperature saturated steam cooks the white fungus, destroys the cell wall, softens the white fungus, and sterilizes it. The softened white fungus enters the drying chamber and is dried with superheated steam. The temperature of the superheated steam is 160° C. and the drying time is 30-45 minutes. After drying, the moisture of Tremella is reduced to a safe moisture content, and the moisture content is ↑10%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap