Injectable silk fibroin bone repair filling sustained-release material, and preparation method and application thereof

A slow-release material, silk fibroin technology, applied in chemical instruments and methods, non-metallic elements, medical science, etc., can solve the problems of inability to improve the performance of composite materials, inability to match defect parts, etc., to promote the growth of osteoblasts, The effect of ensuring mechanical strength and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

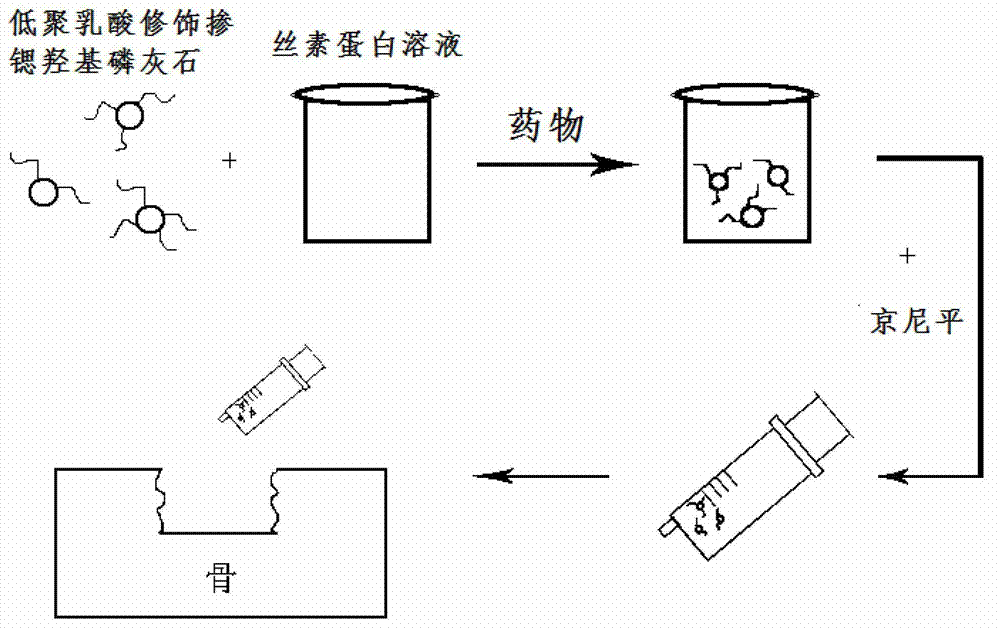

[0017] Correspondingly, the embodiment of the present invention also provides a preparation method of an injectable silk fibroin bone repair filling slow-release material, which includes the following steps:

[0018] S01: obtaining oligomeric lactic acid grafted strontium-doped hydroxyapatite, wherein the molar content of strontium in the oligomeric lactic acid grafted strontium-doped hydroxyapatite is lower than 10%;

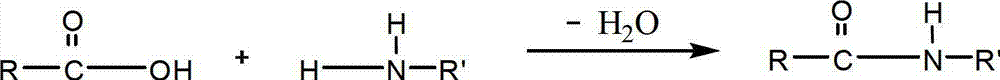

[0019] S02: Mix the oligomeric lactic acid grafted strontium-doped hydroxyapatite with a silk fibroin solution with a mass concentration of 1% to 10%, heat to 30°C to 70°C, and react for 1 to 4 hours to obtain a mixture, wherein, The mass ratio of the oligomeric lactic acid grafted strontium-doped hydroxyapatite to the silk fibroin is 1:9-9:1;

[0020] S03: Mix the mixture with an aqueous solution of genipin with a mass concentration of 1% to 15% to obtain the injectable silk fibroin bone repair filling slow-release material.

[0021] In step S01, the strontiu...

Embodiment 1

[0034] Calcium chloride, strontium chloride and diammonium hydrogen phosphate are used to generate strontium-doped hydroxyapatite, the molar ratio of calcium chloride and strontium chloride is 12:1, and the pH value of the reaction solution is adjusted to 7-10 with ammonia water and hydrochloric acid , After reacting for 2 to 3 hours, aging for 12 hours, filtering and drying to obtain strontium-doped hydroxyapatite.

[0035] Mix 200mL L-lactic acid and 300mL toluene, heat slowly to 160°C and react at a constant temperature for 72h, the water generated in the reaction is removed by azeotropic toluene, the resulting reactant is dissolved in chloroform, settled in cold ethanol, and dried under vacuum at 60°C for 24h To obtain carboxyl-terminated oligomeric lactic acid, the whole reaction process does not add any catalyst. Dissolve 30 g of carboxy-terminated oligomeric lactic acid in 200 mL of toluene, disperse 30 g of strontium-doped hydroxyapatite nanoparticles in the solution, ...

Embodiment 2

[0039] Graft oligomeric lactic acid to strontium-doped hydroxyapatite, wherein the molar percentage of Sr is 9%, add it to the silk fibroin solution with a mass concentration of 1%, heat it to 70°C, and react for 1 hour to obtain a mixture, wherein, the The molar ratio of oligomeric lactic acid grafted strontium-doped hydroxyapatite to silk fibroin is 1:9; a natural cross-linking agent genipin solution (genipin and silk with a mass concentration of 15%) is added to the mixture. The mass ratio of plain protein is 1:100), injected into the defect site to form a hydrogel with certain mechanical strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com