A kind of composite polysaccharide hemostatic material and its preparation method and application

A technology of compound polysaccharide and hemostatic material, applied in the field of clinical surgery, can solve the problems of limited and limited effect, and achieve the effects of complete biodegradation and absorption, high safety and high liquid absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

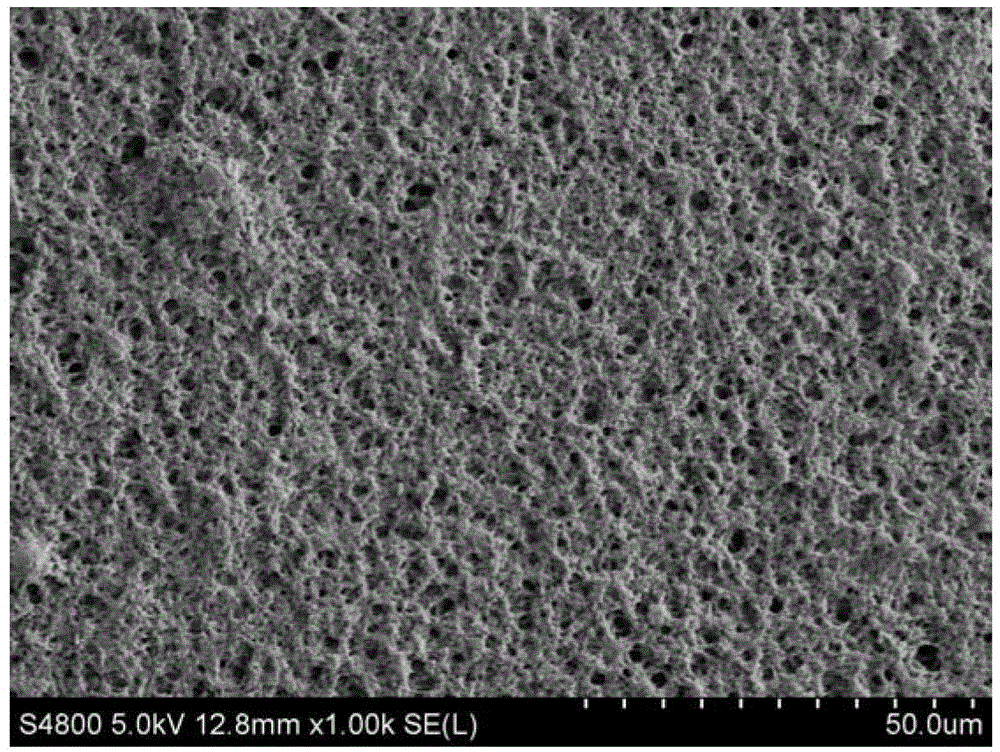

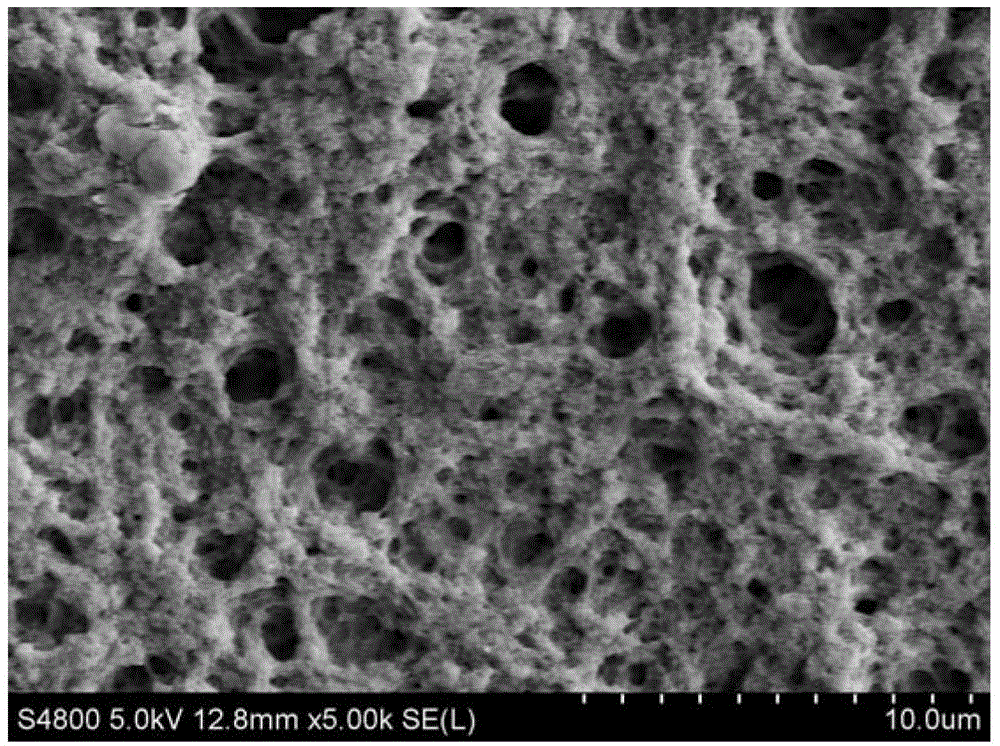

Image

Examples

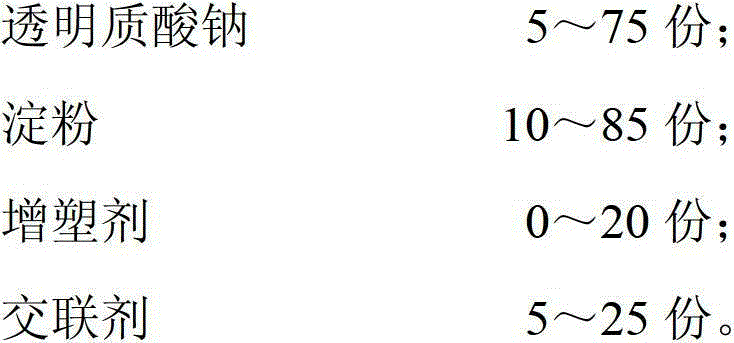

Embodiment 1

[0043] Dissolve 8 grams of acid-thinned starch in 80ml of water, and stir for 4 hours at 60°C with an intensified agitator; dissolve 2g of sodium hyaluronate in 80ml of water, stir well, and mix the sodium hyaluronate solution with 1g of phosphorus oxychloride Add it to the starch solution, stir at 1000rpm for 30min and mix evenly; adjust the pH value of the solution to 9.0 with 1M NaOH, and stir at 1000rpm at 60°C for 15h with an intensified agitator; adjust the pH value of the solution to 6.8 with 1M HCl. After adding washing and refining, pour it into a freeze-drying tray, pre-freeze at -60 degrees Celsius for 3 hours, freeze-dry for 42 hours, smash into granules, and sterilize to obtain the product.

Embodiment 2

[0045] Dissolve 6 grams of potato starch in 70ml of water, and stir for 6 hours at 85°C with a booster stirrer; dissolve 1.5g of sodium hyaluronate in 60ml of water, stir well, and mix the sodium hyaluronate solution with 0.9g of glutaraldehyde And 1g of polyethylene glycol was added to the starch solution, stirred at 45°C for 10 hours with an intensified agitator at 1000rpm; added several times of pure water to wash and refine, poured into a freeze-drying tray, pre-frozen at -80°C for 3 hours, and freeze-dried at -40°C 56 hours, rolled into a film, and sterilized to obtain a product.

Embodiment 3

[0047]Dissolve 5 grams of cornstarch in 50ml of water, stir with a booster mixer at 75°C for 4 hours; dissolve 2g of sodium hyaluronate in 70ml of water, stir well, mix the sodium hyaluronate solution with 0.5g of sodium trimetaphosphate And 1.26g of glycerol was added to the starch solution, stirred at 1000rpm for 30min and mixed evenly; the pH value of the solution was adjusted to 11 with 1M NaOH, and the booster stirrer was stirred at 1000rpm at 60°C for 8h; the pH value of the solution was adjusted to 7.0 with 1M HCl. Add pure water to wash and refine, then pour into a freeze-drying tray, pre-freeze at -40°C for 8 hours, freeze-dry for 48 hours, and sterilize to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com