Intermittent extractive distillation and separation method for isopropyl ether-isopropanol mixture

A technology of extractive rectification and separation method, applied in the field of intermittent extraction, rectification and separation of isopropyl ether-isopropyl alcohol mixture, can solve the problems of inability to separate and difficult to obtain pure isopropyl ether, etc., achieves easy control, is beneficial to Environmental protection, avoid the effect of poor solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Raw materials to be separated: isopropyl ether (99.9%), isopropanol (99.9%)

[0023] Extractant: Ethylene glycol methyl ether (99.8%)

[0024] Batch extractive distillation tower (packed tower): the separation process is as follows:

[0025] Tower inner diameter: Φ40mm (built-in θ4×4 mesh ring packing)

[0026] Solvent ratio: 3:1

[0027] Reflux ratio: 1~4

[0028] Taft kettle temperature: 60~125℃

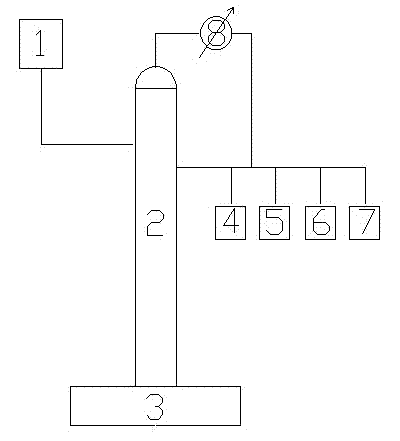

[0029] by figure 1 The shown flow device adopts intermittent operation to separate the mixture of isopropyl ether and isopropanol. The specific process is as follows: the diameter of the extractive distillation tower used is Φ40mm, and theta mesh ring packing is installed inside. The packing layer is 2000mm. At 150mm, add 1500ml of isopropanol-isopropyl ether mixture (including 83.7% isopropyl ether and 16.3% isopropyl ether, both in mass fraction) to the kettle of the heating tower, add the extractant ethylene glycol methyl ether to the High slot. Turn on the power s...

Embodiment 2

[0031] Raw materials to be separated: isopropyl ether (99.9%), isopropanol (99.9%)

[0032] Extractant: Ethylene glycol methyl ether (99.8%)

[0033] Batch extractive distillation tower (packed tower): the separation process is as follows:

[0034] Tower inner diameter: Φ40mm (built-in θ4×4 mesh ring packing)

[0035] Solvent ratio: 3:1

[0036] Reflux ratio: 1~4

[0037] Taft kettle temperature: 60~125℃

[0038] by figure 1The shown flow device adopts intermittent operation to separate the mixture of isopropyl ether and isopropanol. The specific process is as follows: the diameter of the extractive distillation tower used is Φ40mm, and theta mesh ring packing is installed inside. The packing layer is 2000mm. At 150mm, add 1500ml of isopropanol-isopropyl ether mixture (including 85.5% isopropyl ether and 14.5% isopropyl ether, both of which are mass fractions) in the heating tower kettle, add the extractant ethylene glycol methyl ether to the High slot. Turn on the powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com