Green preparation technology of dihydroquercetin

A technology of dihydroquercetin and quercetin is applied in the field of green preparation of dihydroquercetin, and can solve the problems of inability to realize industrialized production and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

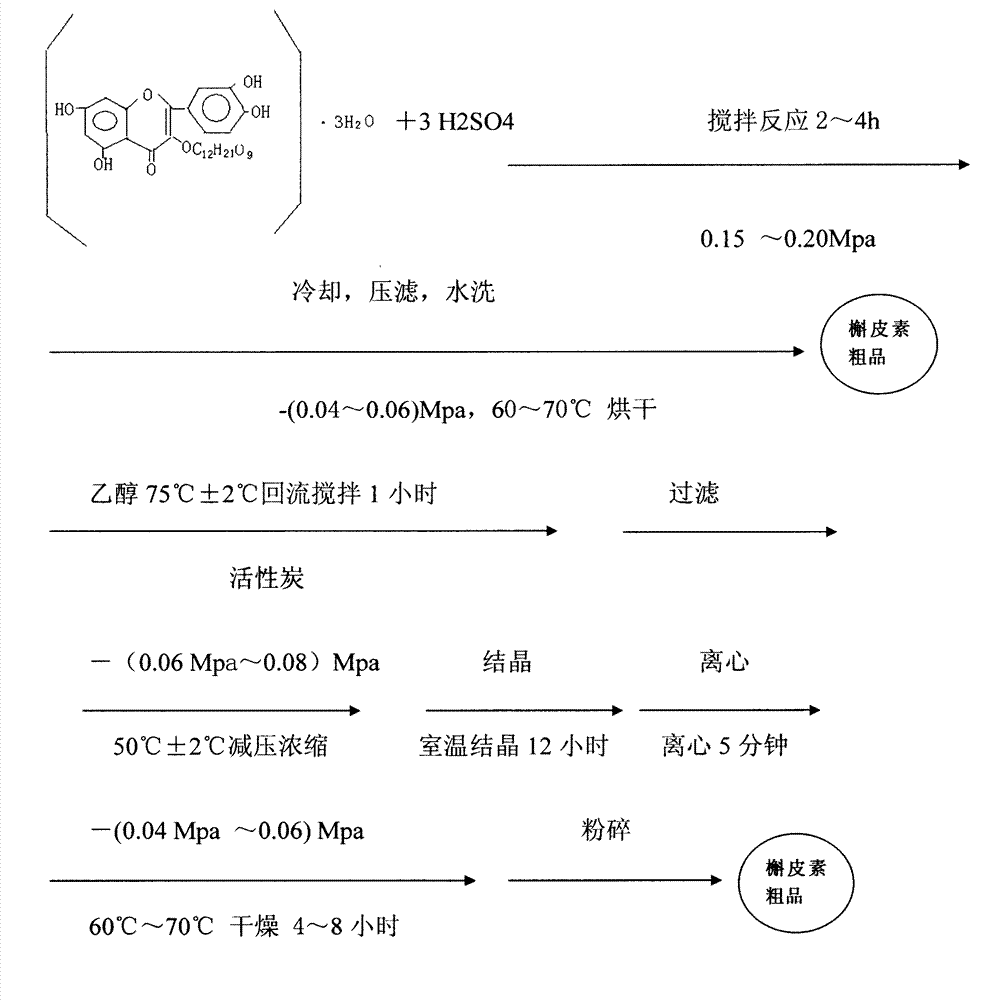

[0015] Method 1: Close the mouth of the reaction kettle, pump 1400-1600Kg of purified water with accurate measurement into the reaction kettle, and then pump in 10-15Kg of concentrated sulfuric acid. Slowly add 200Kg of rutin crude product from the reaction kettle mouth, seal the reaction kettle mouth, start stirring, open the heat-carrying steam valve of the reaction kettle to heat, open the circulating condensed water, close the heat-carrying steam valve when the pressure gauge indication pressure on the reaction kettle reaches 0.15MPa, keep The pressure in the kettle is at 0.15MPa~0.20MPa for 2~4 hours. After 1 hour of reaction, take a sample from the sampling port for detection. After the reaction is complete, start to reduce the pressure, turn on the condensate water to cool, and the temperature reaches 50~60℃. Connect the plate and frame filter press and start Pressure filtration, after pressure filtration of the hydrolyzate, collect the filtrate to the sedimentation tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com