Preparation method of yeast beta-D-glucan

A technology of glucan and yeast, which is applied in the field of preparation of yeast β-D-glucan, can solve problems such as limited industrial scale production, environmental pollution, and damage to human health, and achieves significant economic benefits and environmental protection significance. The preparation conditions are mild and the effect of realizing industrial scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

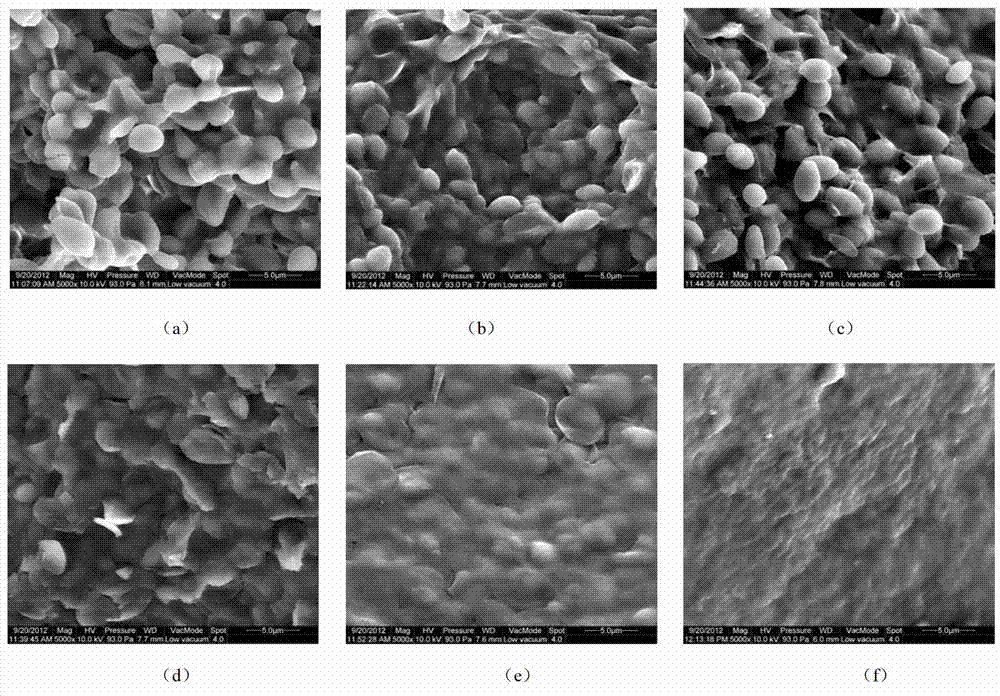

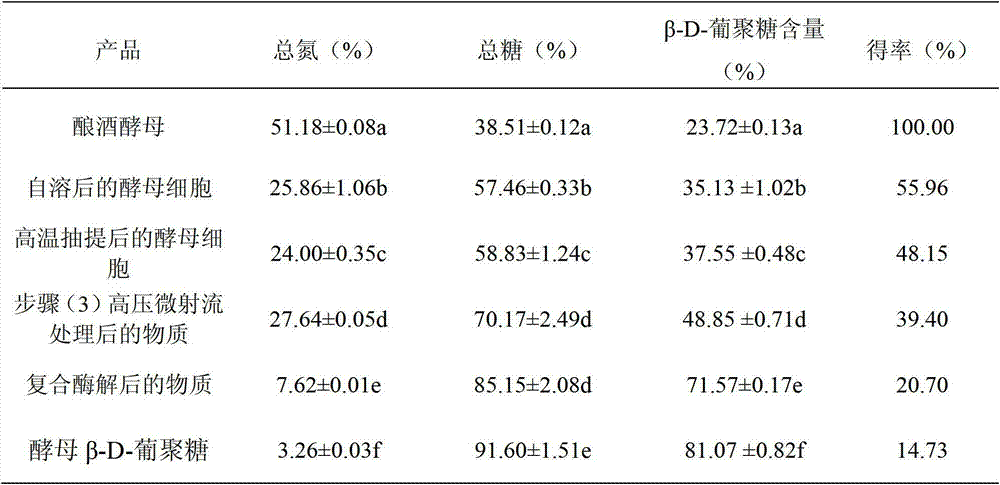

[0048] Embodiment 1, preparation of yeast β-D-glucan

[0049] (1) Autolysis: use Saccharomyces cerevisiae with high β-D-glucan content (FFLM2.0016, its preservation number is CGMCCNo.3730) as raw material, wash with water, centrifuge to remove impurities, and add water at a volume ratio of 1:5 to prepare Add NaCl to the suspension to make the final concentration 3%, place it in a constant temperature water bath shaker at pH 5.0 and 55°C to induce autolysis for 24 hours, raise the temperature to 85°C, keep it warm for 15 minutes to inactivate the enzyme activity, centrifuge, and wash with water Precipitate 3 times;

[0050] (2) High-temperature extraction: Add 0.02mol / L, pH7.5 phosphate buffer to the precipitate obtained in step (1) at a specific mass ratio of 1:5 to prepare a suspension, shake in a constant temperature water bath at 95°C Extract at high temperature in a container for 4 hours, centrifuge, wash and precipitate with water twice;

[0051] (3) High-pressure micro-j...

Embodiment 2

[0062] Embodiment 2, preparation of yeast β-D-glucan

[0063] (1) Autolysis: use Saccharomyces cerevisiae with high β-D-glucan content (FFLM2.0016, its preservation number is CGMCCNo.3730) as raw material, wash with water, centrifuge to remove impurities, and add water at a volume ratio of 1:20 to prepare Add NaCl to the suspension to make the final concentration 3%, place it in a constant temperature water bath shaker at pH 5.0 and 55°C to induce autolysis for 24 hours, raise the temperature to 100°C, keep it warm for 10 minutes to inactivate the enzyme, centrifuge, and wash with water Precipitate 3 times;

[0064] (2) High-temperature extraction: Add 0.02mol / L, pH7.5 phosphate buffer solution to the precipitate obtained in step (1) at a specific mass ratio of 1:20 to prepare a suspension, shake in a constant temperature water bath at 95°C Extract at high temperature in a container for 4 hours, centrifuge, wash and precipitate with water twice;

[0065] (3) High-pressure mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com