Ultra-high molecular weight polyethylene/carbon nanotube oil tube lining tube and preparation method thereof

A technology of ultra-high molecular weight and carbon nanotubes, applied in the field of ultra-high molecular weight polyethylene/carbon nanotube tubing lining pipes and its preparation, can solve the problems of poor compatibility of two-phase interface, poor mechanical properties and other properties of composite materials, etc. , to achieve the effect of improving processing plasticizing ability, excellent mechanical properties, and increasing heat distortion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

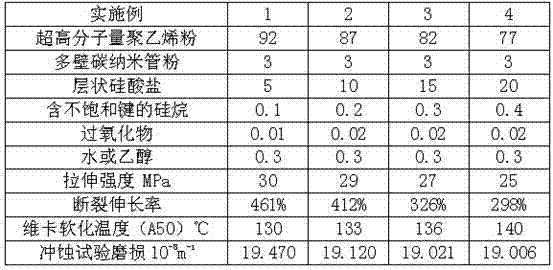

Embodiment 1

[0028] 1) Coupling 5 parts of layered silicate with large aspect ratio and 0.1 part of unsaturated bond-containing silane is performed in a high-speed mixer.

[0029] 2) Add 92 parts of ultra-high molecular weight polyethylene powder, 3 parts of carbon nanotube powder, 0.01 part of peroxide, 0.3 part of water or ethanol into a high-speed mixer in sequence, stir at high speed for 5 minutes, and mix well.

[0030] 3) Extrude the above treated mixture into a pipe on a specially customized involute single-screw extruder.

[0031] The ultra-high molecular weight polyethylene powder is industrially produced polyethylene with a viscosity average molecular weight of 2.5 million to 4.5 million.

[0032] The multi-walled carbon nanotube powder has a length of 10-30um, a diameter of 1-9nm, and a purity of CNT≥90%.

[0033] The layered silicate is mica, kaolinite, halloysite, sepiolite, talc, Inorganic mineral of wollastonite, montmorillonite or palygorskite.

[0034] The sheet thickne...

Embodiment 2

[0039] 1) Coupling 10 parts of layered silicate with a large aspect ratio and 0.2 parts of silane containing unsaturated bonds is performed in a high-speed mixer.

[0040] 2) Add 87 parts of ultra-high molecular weight polyethylene powder, 3 parts of carbon nanotube powder, 0.02 part of peroxide, 0.3 part of water or ethanol into a high-speed mixer in sequence, stir at high speed for 5 minutes, and mix well.

[0041] 3) Extrude the above treated mixture into a pipe on a specially customized involute single-screw extruder.

[0042] Others are basically the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0044] 1) Coupling 15 parts of layered silicate with a large aspect ratio and 0.3 parts of silane containing unsaturated bonds is performed in a high-speed mixer.

[0045] 2) Add 82 parts of ultra-high molecular weight polyethylene powder, 3 parts of carbon nanotube powder, 0.02 part of peroxide, 0.3 part of water or ethanol into a high-speed mixer in sequence, stir at high speed for 5 minutes, and mix well.

[0046] 3) Extrude the above treated mixture into a pipe on a specially customized involute single-screw extruder.

[0047] Others are basically the same as those in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com