Sulphide red fluorescent material for white-light LED (light-emitting diode) and preparation method for same

A technology of red fluorescence and fluorescent materials, applied in the fields of luminescent materials, chemical instruments and methods, chemical industry, etc., can solve the problems of loss of conversion luminescence characteristics, conditions of excellent light sources, slow chemical reactions, etc., to achieve industrialized large-scale production, Exciting wide-ranging, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

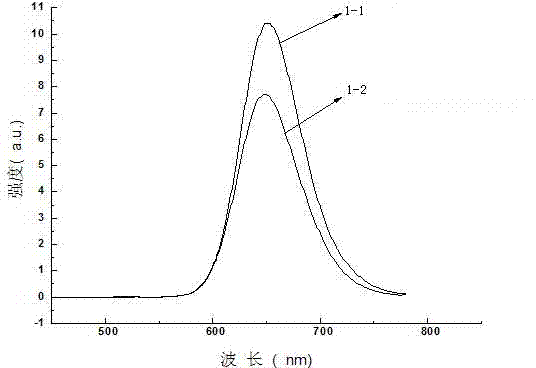

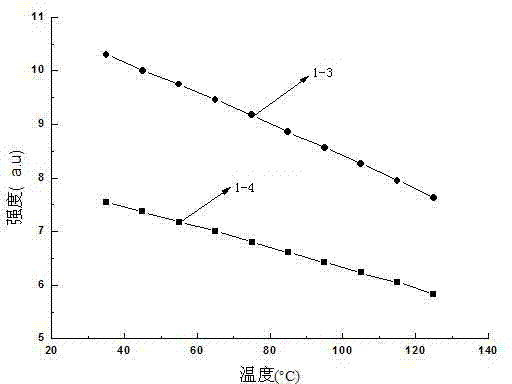

[0037] Example 1: Preparation of Ca 0.9799 Mg 0.0001 Ga 0.02 S: 0.05 Eu 2+ Fluorescent material.

[0038] Step 1: Weigh 2.9397g CaCO3(AR), 0.1125gGa 2 O 3 (The purity is 99.999%), 0.2640g Eu 2 O 3 (Purity is 99.999%), 2.8221gS (AR), 0.0015g basic magnesium carbonate (AR), and mix thoroughly to form a mixture, and then weigh out 0.0614g NH 4 F (AR) is used as a co-solvent. Place the above weighing material in an agate mortar, add anhydrous ethanol with a mass ratio of 0.8:1 to the mixture as the ball milling medium, and then add zirconia balls, the total amount of all substances added does not exceed 2 in the agate mortar / 3, then ball mill on a planetary ball mill for 3 hours; put the ground sample into a drying oven at 100°C for 4 hours;

[0039] Step 2: Put the powder dried in step 1 in an atmosphere furnace, in Ar / H 2 Roast at 1000°C for 6 hours in an atmosphere, take it out and grind it after cooling in the furnace, and sieve it with a 100-mesh standard inspection sieve to ob...

Embodiment 2

[0042] Example 2: Preparation of Ca 0.89 Mg 0.01 Ga 0.1 S: 0.05 Eu 2+ Fluorescent material.

[0043] Step 1: Weigh 2.6700g CaCO 3 (AR), 0.0562g Ga 2 O 3 (The purity is 99.999%), 0.2640g Eu 2 O 3 (Purity is 99.999%), 2.5632gS (AR), 0.1457g g basic magnesium carbonate (AR), and mix thoroughly to form a mixture, and then weigh out 0.0621gNH 4 F (AR) is used as a co-solvent. Place the above weighing material in an agate mortar, add coarse grinding liquid with a mass ratio of 0.8:1 to the mixture as the ball milling medium, and then add zirconia balls. The total amount of all substances added does not exceed 2 in the agate mortar. / 3, then ball mill on a vibrating ball mill for 3 hours; put the ground sample into a drying oven at 100°C for 4 hours;

[0044] Step 2: Put the powder dried in step 1 in an atmosphere furnace, in N 2 / H 2 Roast at 1000°C for 6 hours in an atmosphere, take it out and grind it after cooling in the furnace, and sieve it with a 100-mesh standard inspection siev...

Embodiment 3

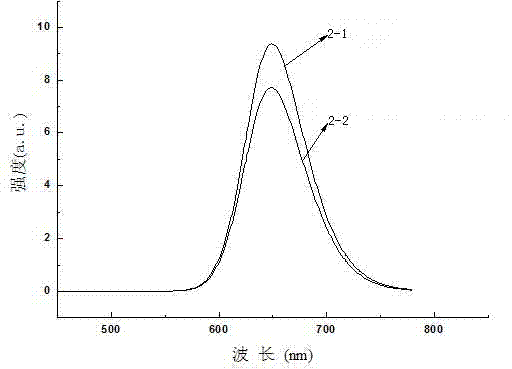

[0047] Example 3: Preparation of Ca 0.45 Mg 0.05 Al 0.5 S: 0.05 Eu 2+ Fluorescent material.

[0048] Step 1: Weigh 0.7560g CaO(AR), 0.7650g Al 2 O 3 (AR), 0.0600gMgO(AR), 0.2640g Eu 2 O 3 (The purity is 99.999%), 1.2960gS(AR), and mix well to form a mixture, and then weigh out 0.0314gNH 4 F (AR) is used as a co-solvent. Put the above weighing material in an agate mortar, add anhydrous ethanol with a mass ratio of 1.2:1 to the mixture as the ball milling medium, and then add zirconia balls, the total amount of all substances added does not exceed 2 in the agate mortar / 3, then ball mill on a roller ball mill for 3 hours; put the ground sample into a drying oven at 100°C for 4 hours;

[0049] Step 2: Put the powder dried in step 1 in an atmosphere furnace, in N 2 / C powder is roasted at 1250℃ for 4 hours, after cooling in the furnace, it is taken out, ground and sieved, and sieved with a 100-mesh standard inspection sieve to obtain Ca 0.45 Mg 0.05 Al 0.5 S: 0.05 Eu 2+ Red fluorescen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com