Waste heat recovery system of automobile exhaust pipe and control method thereof

A technology for waste heat recovery and automobile exhaust, which is used in exhaust devices, mufflers, internal combustion piston engines, etc., can solve the problem of catalytic converter catalyst sintering into agglomerates, affecting the reliability of baffles and their actuators, and failing to make full use of them energy and other issues, to achieve the effect of improving efficiency, preventing sintering agglomeration failure, and being easy to promote and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

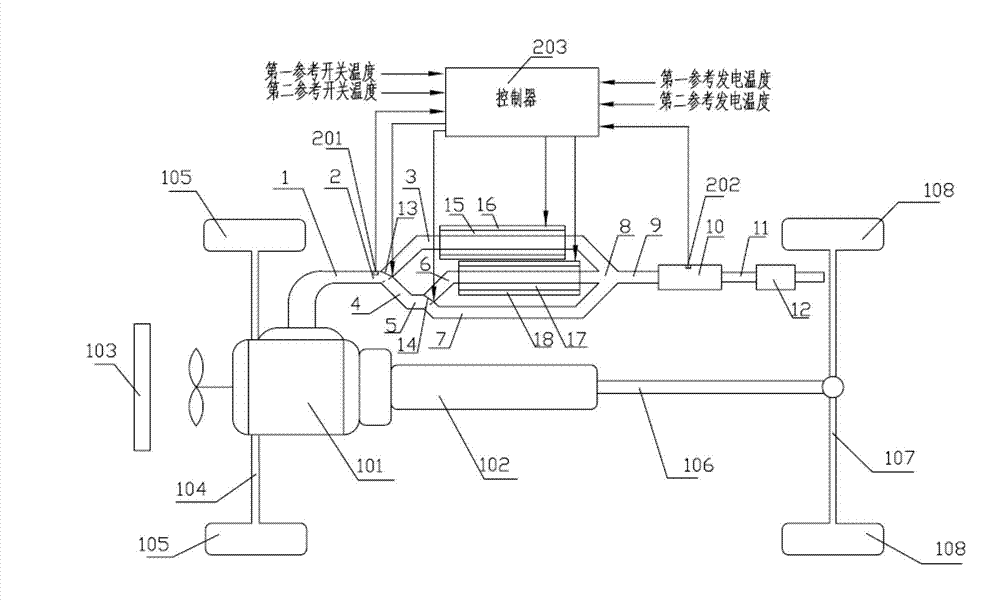

[0045] like figure 1 The shown car includes: front axle 104, front wheel 105, drive shaft 106, rear axle 107, rear wheel 108 jointly form a vehicle frame structure, engine 101, gearbox 102 and radiator 103 are included on the vehicle frame.

[0046] A waste heat recovery system for an automobile exhaust pipe, comprising a first exhaust main pipe 1 for discharging engine exhaust gas, the output port of the first exhaust main pipe 1 is respectively connected to the first exhaust branch pipe 3 through the first tee 2 The input port of the input port and the exhaust sub-conduit 4, the output port of the exhaust sub-conduit 4 is respectively connected to the input port of the second exhaust branch pipe 6 and the input po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com