Solution method electrolyte thin film transistor and preparation method thereof

A technology for electrolyte thin films and transistors, which is applied in the manufacture of transistors, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of restricting the industrial development of thin film transistors, increasing device processing costs and energy consumption, and complicating the processing process. The effect of reducing processing cost, reducing working voltage and simplifying processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

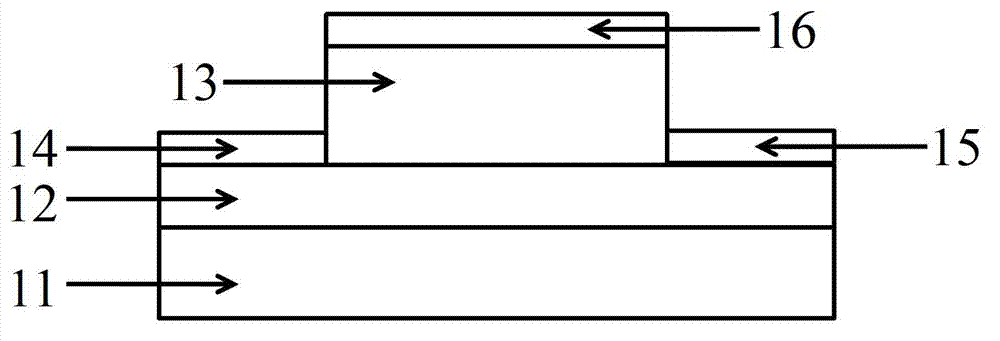

[0033] see Figure 2A — Figure 2D , the specific steps of the preparation method of the solution method bipolar thin film transistor are as follows:

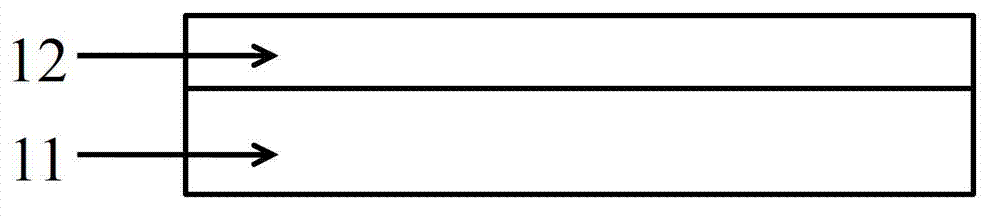

[0034] 1) Preparing the semiconductor layer 12 on the insulating substrate 11, the preparation method used is a solution method such as spin coating, inkjet printing, screen printing or pulling method;

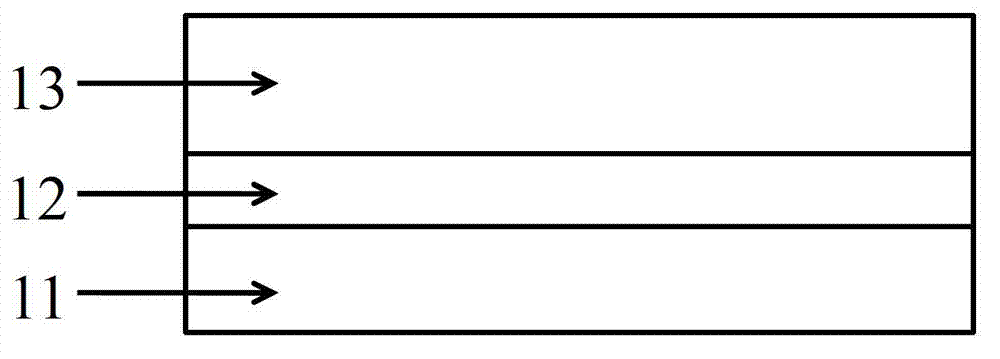

[0035] 2) Preparing the electrolyte insulating layer 13 on the semiconductor layer 12, the preparation method used is solution spin coating, spray coating or scraping coating of the electrolyte insulating layer solution;

[0036] 3) Perform patterning treatment on the electrolyte insulating layer 13, the treatment method used is to use a mask with a certain pattern for photocrosslinking, and then use a certain solvent for elution treatment, so that the electrolyte insulation layer 13 after the elution treatment Only covering part of the upper surface of the semiconductor layer 12, exposing the semiconductor layer 12 on both s...

Embodiment 1

[0040] 1) Prepare a semiconductor layer 12 on a glass insulating substrate 11, the material of the semiconductor layer 12 is an electronically conductive inorganic oxide semiconductor processed by a solution method, and the preparation method used is a solution method spin coating.

[0041] 2) Prepare an electrolyte insulating layer 13 on the semiconductor layer 12, the electrolyte insulating layer 13 is a polymer electrolyte insulating layer material PVA+KF processed by a solution method, and the preparation method used is spin coating an electrolyte insulating layer solution by a solution method.

[0042] 3) Perform patterning treatment on the electrolyte insulating layer 13, the treatment method used is to use a mask with a certain pattern for photocrosslinking, and then use a certain solvent for elution treatment, so that the electrolyte insulation layer 13 after the elution treatment Only part of the upper surface of the semiconductor layer 12 is covered, and the semicondu...

Embodiment 2

[0045] 1) Prepare the semiconductor layer 12 on the insulating substrate 11 of the plastic film, the material of the semiconductor layer 12 is a small molecule semiconductor with hole conduction processed by solution method, and the preparation method used is inkjet printing by solution method.

[0046]2) Prepare an electrolyte insulating layer 13 on the semiconductor layer 12, the electrolyte insulating layer 13 is a polymer electrolyte insulating layer material PS-PMMA-PS+[EMIM][TFSI] processed by a solution method, and the preparation method used is spray coating by a solution method Electrolyte insulating layer solution.

[0047] 3) Perform patterning treatment on the electrolyte insulating layer 13, the treatment method used is to use a mask with a certain pattern for photocrosslinking, and then use a certain solvent for elution treatment, so that the electrolyte insulation layer 13 after the elution treatment Only part of the upper surface of the semiconductor layer 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com