Catalyst for preparing ketone via cyclododecanol dehydrogenation and preparation method for same

A kind of cyclododecanol and catalyst technology, applied in the catalyst and preparation field of cyclododecanol dehydrogenation to ketone, can solve the problem that the catalyst is not further researched and modified, is not

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

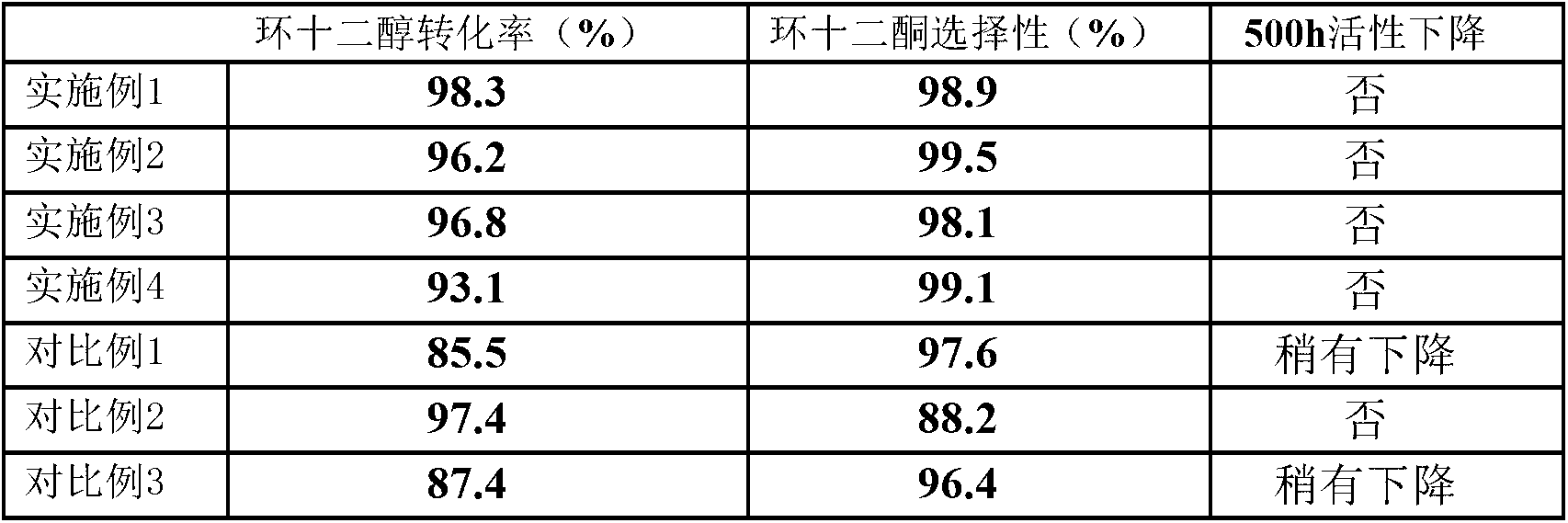

Examples

Embodiment 1

[0023] (1) Weigh 121g of copper nitrate trihydrate and 146g of zinc nitrate hexahydrate respectively, add them to 750ml of deionized water and stir to dissolve, so as to form a mixed solution of copper nitrate and zinc nitrate.

[0024] (2) Prepare a mixed solution of ammonium carbonate with a concentration of 1mol / L and ammonia water with a concentration of 0.6mol / L as a precipitant.

[0025] (3) Slowly add the above-mentioned salt solution and precipitant into a flask filled with 100ml of deionized water at the same time, and vigorously stir at the same time, and always control the pH value between 8 and 9 during the dropping process. After the dropwise addition was complete, vigorous stirring was continued for 3 hours.

[0026] (4) Suction filter and wash the above precipitate until the washing solution is neutral; then dry the washed precipitate at 100°C for 12 hours.

[0027] (5) Roast the dried precipitate in a tube furnace at 450°C for 6 hours, during which time NH 3 ...

Embodiment 2

[0032] (1) Weigh 160g of copper nitrate trihydrate and 96g of zinc nitrate hexahydrate respectively, add them to 750ml of deionized water and stir to dissolve, so as to form a mixed solution of copper nitrate and zinc nitrate.

[0033] (2) to (6) are the same as in Example 1.

[0034] (7) Weigh a certain amount of manganese nitrate and dissolve it in deionized water to prepare a 4wt% impregnation solution.

[0035] (8) As in Example 1, a CuZnMn dehydrogenation catalyst was prepared.

Embodiment 3

[0037] (1) Weigh 81g of copper nitrate trihydrate and 192g of zinc nitrate hexahydrate respectively, add them to 750ml of deionized water and stir to dissolve, so as to form a mixed solution of copper nitrate and zinc nitrate.

[0038] (2) to (6) are the same as in Example 1.

[0039] (7) Weigh a certain amount of lanthanum nitrate and dissolve it in deionized water to prepare a 4wt% impregnation solution.

[0040] (8) As in Example 1, a CuZnLa dehydrogenation catalyst was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com