Method for synthesizing ZSM-35 molecular sieve

A technology of ZSM-35 and synthesis method, which is applied to iron-conglomerate crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of polluting the environment, reducing synthesis cost, and high ratio, and achieves green and environmental protection in the preparation process , Reduce production costs, and the effect of cheap and easy-to-get raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take 40g of ZSM-35 molecular sieve and 1000mL of 1mol / L sodium hydroxide solution in a beaker, stir at room temperature for 30min, transfer to a closed reaction kettle, and treat in an oven at 120°C for 4h. The resulting suspension is the structure-directing agent and is ready for use.

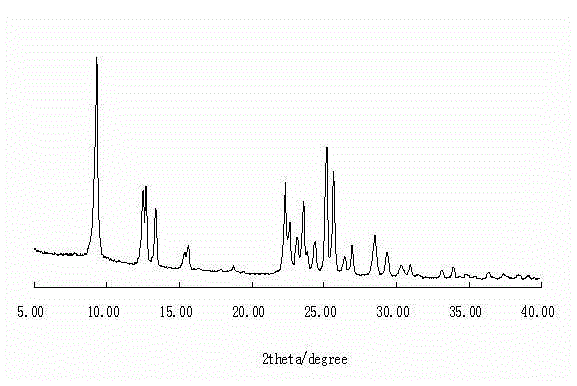

[0029] Take 12 g of sodium hydroxide and 5.3 g of sodium aluminate in 500 mL of distilled water, and stir vigorously until they are completely dissolved. Add 47 g of white carbon black slowly and stir vigorously for 30 min. Then add 30mL of the structure directing agent prepared in the previous step and stir vigorously for 30 min. Then put it into a closed reactor and crystallize in an oven at 150°C for 4 days. The obtained product was washed 4 times with distilled water to neutrality, and dried at 120°C for 12 hours. The obtained sample number was CL1, and the obtained sample was as follows: figure 1 As shown, it is pure ZSM-35 molecular sieve without other impurities.

Embodiment 2

[0031]Take 30g of ZSM-35 molecular sieve and 1000mL of 1.1mol / L sodium hydroxide solution in a beaker, stir at room temperature for 20min, transfer to a closed reaction kettle, and treat in an oven at 130°C for 4h. The resulting suspension is the structure-directing agent and is ready for use.

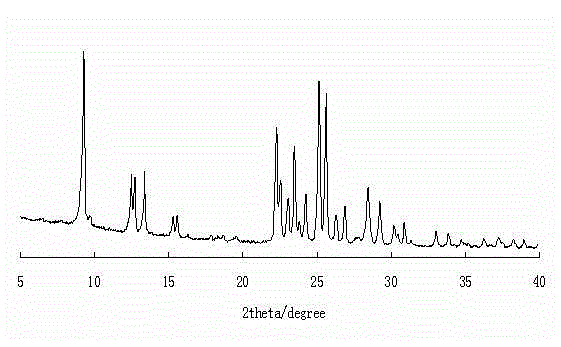

[0032] Take 15 g of sodium hydroxide and 6.5 g of sodium aluminate in 600 mL of distilled water, and stir vigorously until they are completely dissolved. Add 50 g of white carbon black slowly and stir vigorously for 20 min. Then add 20mL of the structure-directing agent prepared in the previous step, and stir vigorously for 25 min. Then put it into a closed reactor and crystallize in an oven at 155°C for 2.5 days. The obtained product was washed 4 times with distilled water to neutrality, and dried at 120°C for 12 hours. The obtained sample number was CL2, which was pure ZSM-35 molecular sieve.

Embodiment 3

[0034] Take 50g of ZSM-35 molecular sieve and 800mL of 1.5mol / L sodium hydroxide solution in a beaker, stir at room temperature for 30min, transfer to a closed reaction kettle, and treat in an oven at 130°C for 2.5h. The resulting suspension is the structure-directing agent and is ready for use.

[0035] Take 11.6 g of sodium hydroxide and 4.3 g of sodium aluminate in 450 mL of distilled water, and stir vigorously until they are completely dissolved. Add 38 g of white carbon black slowly and stir vigorously for 30 min. Then add 35mL of the structure directing agent prepared in the previous step and stir vigorously for 30 min. Then put it into a closed reactor and crystallize in an oven at 140°C for 5 days. The obtained product was washed 4 times with distilled water to neutrality, and dried at 120°C for 12 hours. The obtained sample number was CL3, which was pure ZSM-35 molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com