Method for preparing hollow ball of sulfide and oxide of nickel

A chalcogenide and hollow sphere technology, applied in binary selenium/tellurium compounds, nickel oxide/nickel hydroxide, nickel sulfide, etc., can solve the problem of difficulty in synthesizing nickel disulfide crystals, and achieve easy operation and experimental scheme. Simple, low-equipment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, the preparation of nickel disulfide hollow sphere

[0026] Weigh 0.5mmol hexahydrate and nickel nitrate into a 50ml reactor with 20ml deionized water, then add 2mmol L-cysteine and 0.5mmol urea, ultrasonicate at room temperature, and then put the reactor into 140 °C heating for 24 hours, filtering and washing to obtain nickel disulfide hollow spheres.

Embodiment 2

[0027] Embodiment 2, the preparation of nickel sulfide and nickel oxide hollow spheres

[0028] The obtained nickel disulfide is respectively roasted at 350-450° C. and 650-800° C. for 1 hour to obtain nickel monosulfide and nickel oxide hollow spheres respectively.

Embodiment 3

[0029] Embodiment 3, the preparation of nickel diselenide and nickel ditelluride hollow spheres

[0030] 0.5mmol nickel disulfide powder is put into the reactor that has the hydrazine hydrate of 20ml, then add 1mmol selenous acid and 0.5mmol tellurous acid respectively, heat 24 hours under 140 ℃ of conditions, filter, wash to obtain disulfide Nickel selenide and nickel ditelluride hollow spheres.

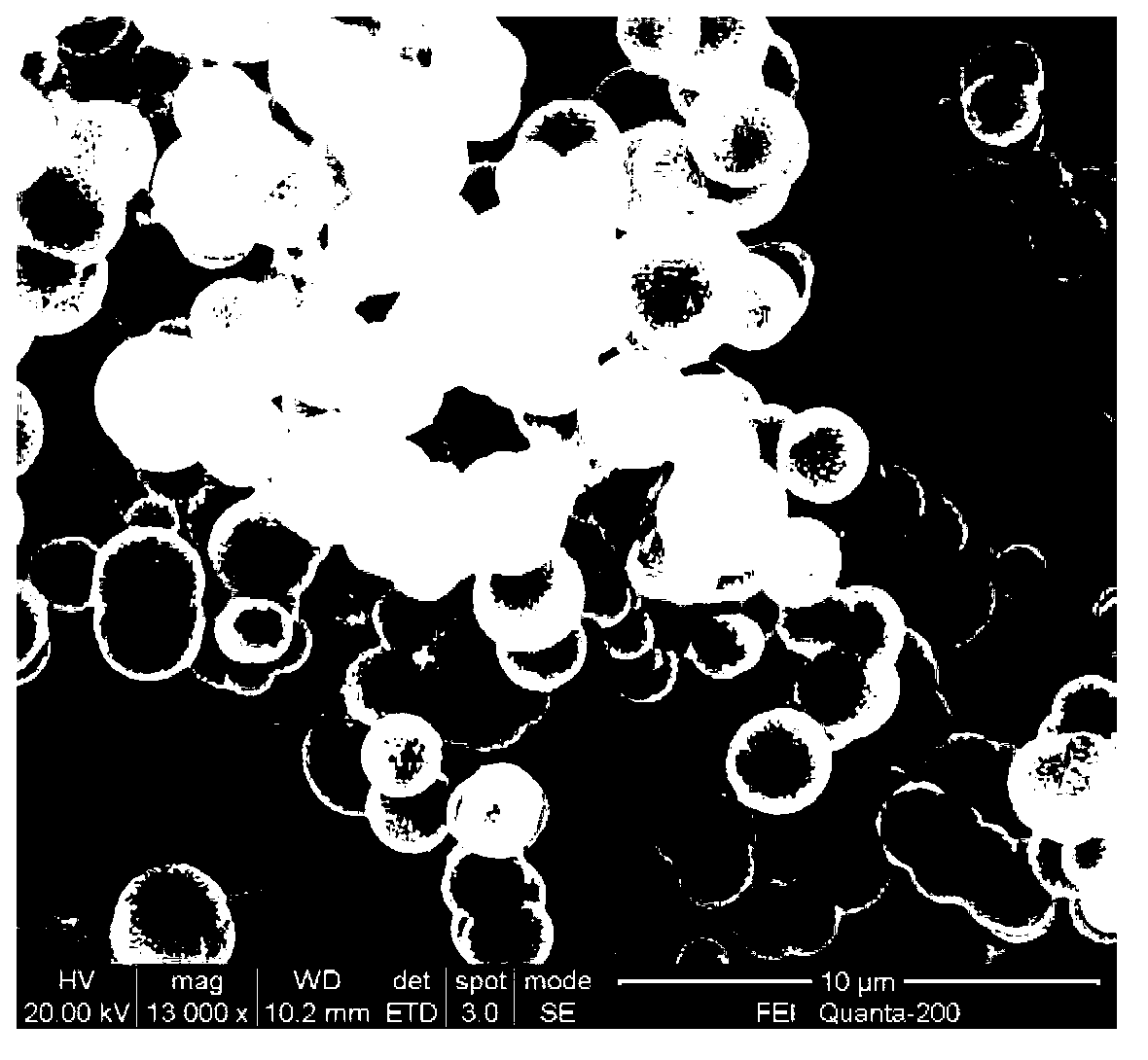

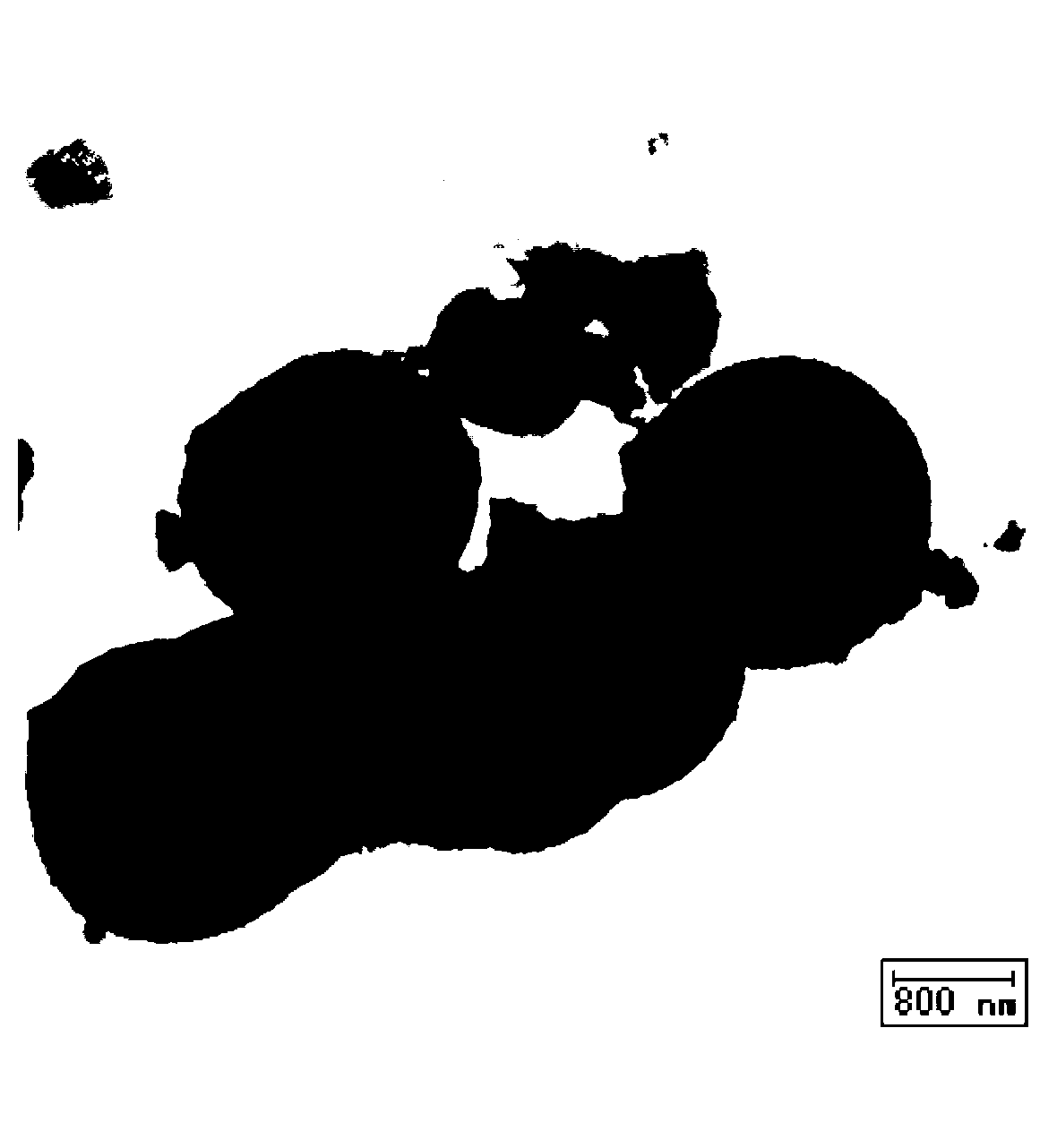

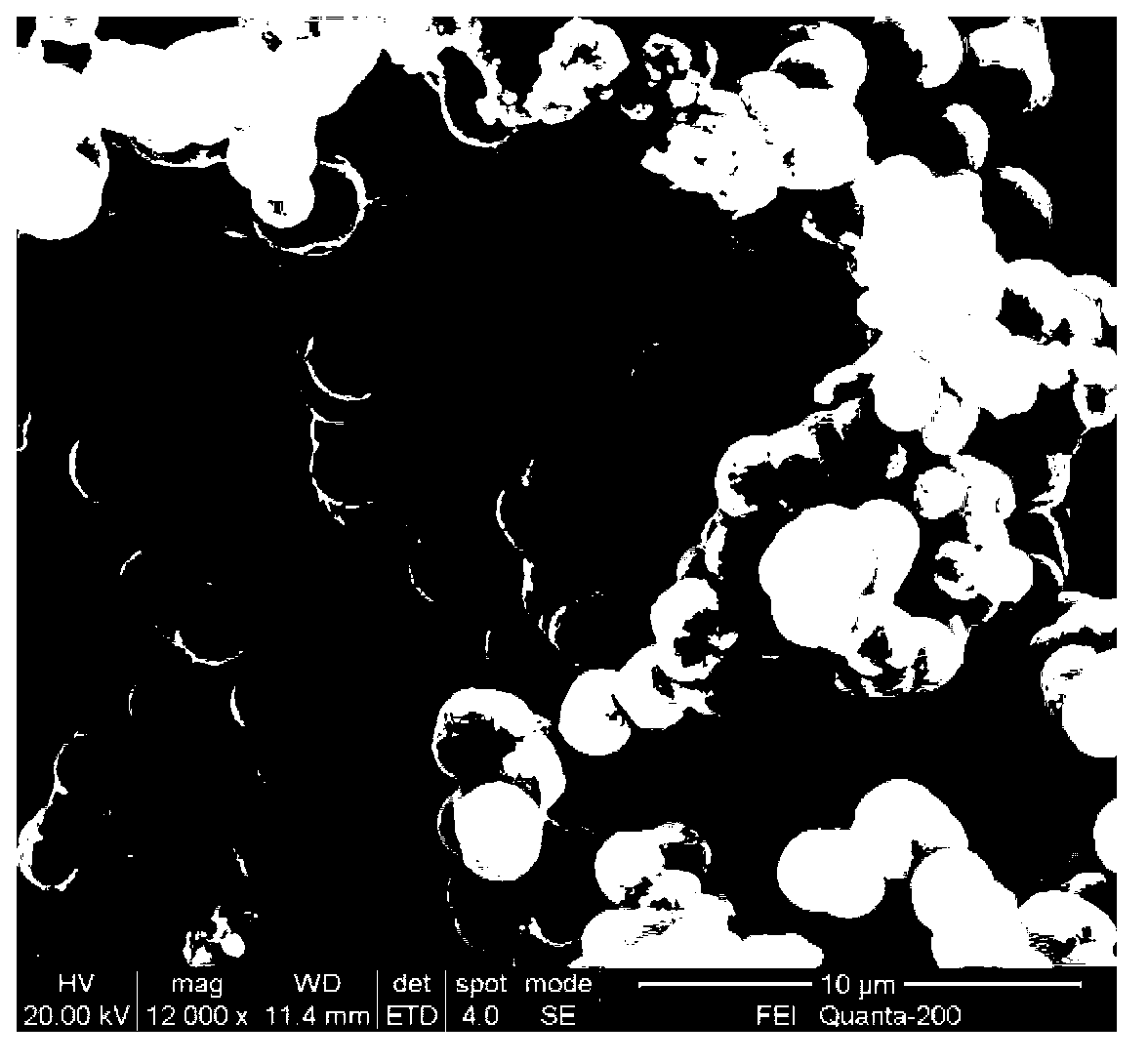

[0031] Synthetic nickel chalcogenides and oxide hollow spheres such as Figure 1-6 As shown, it shows that the hollow nanospheres have a uniform diameter of about 2 microns and a shell thickness of 60-150 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com