Method for removing oxytetracycline from livestock and poultry breeding wastewater by biomass charcoal of straws

A technology of livestock and poultry breeding wastewater and biochar, applied in the field of biochar removal of oxytetracycline in water, can solve problems such as time-consuming, high cost, and impact of antibiotic migration, and achieve cost-environmental friendliness, reasonable and effective use, and low cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

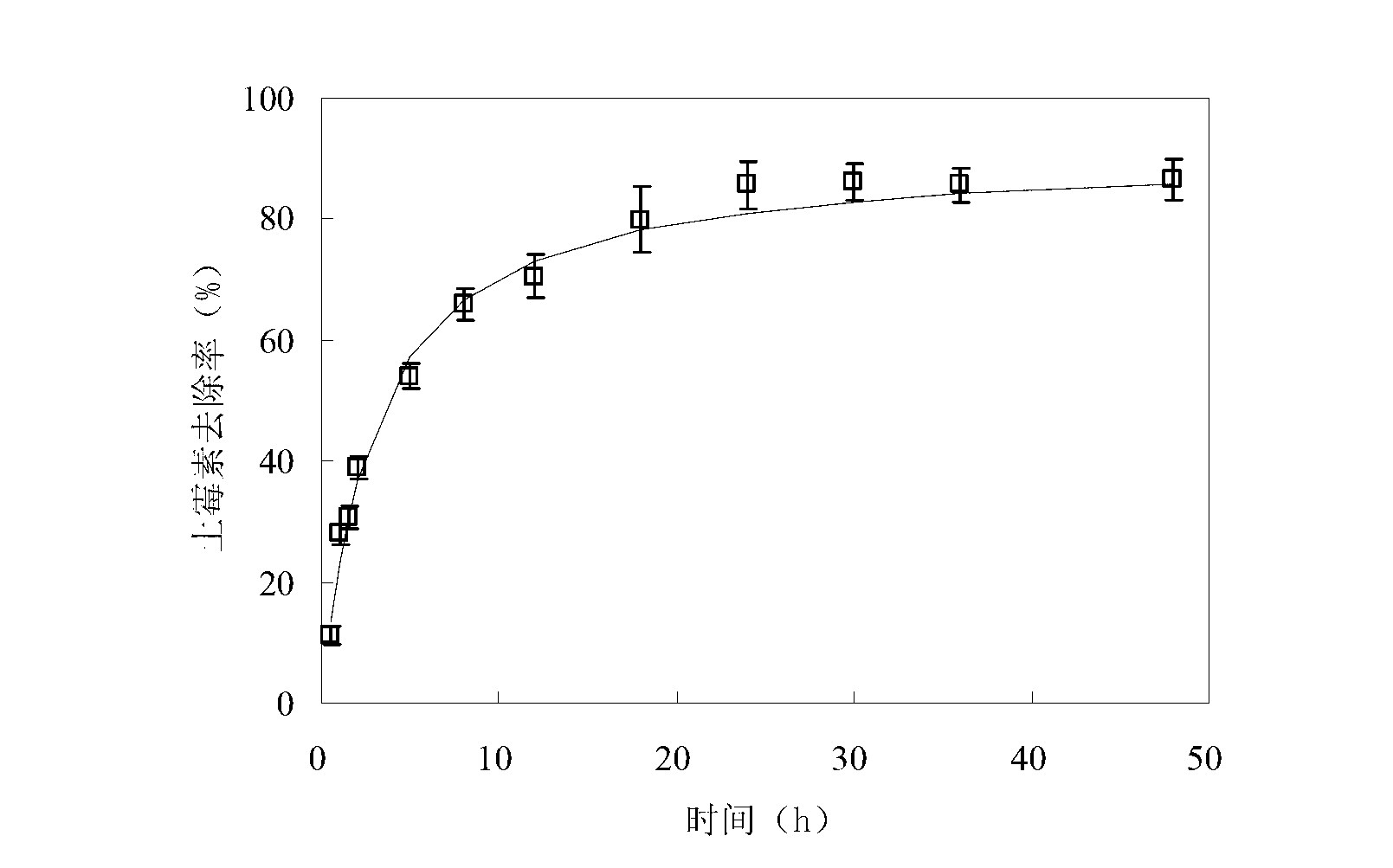

[0028] Weighed 0.2 g of biochar prepared at 300 °C and added it to 20 mL of an aqueous solution with a concentration of oxytetracycline of 10 mg / L at a solid-to-liquid ratio of 1:100, and adjusted the pH of the system to 5.5 with 0.1 mol / L HCl. Shake at a speed of 15 rpm in the dark, remove the sample bottle at 0.5, 1, 1.5, 2, 5, 8, 12, 18, 24, 30, 36 and 48 h, filter with a 0.45 μm glass fiber membrane, and efficiently Liquid chromatography (HPLC) was used to determine the residual concentration of oxytetracycline in the filtrate, and each treatment was set up with 3 replicates. The result is as figure 1 It was shown that with the increase of shaking time, the adsorption amount of oxytetracycline on biochar first increased rapidly, then increased slowly, and the adsorption amount no longer increased significantly after 24 h. The removal rate of oxytetracycline was 86% at adsorption equilibrium.

[0029]

Embodiment 2

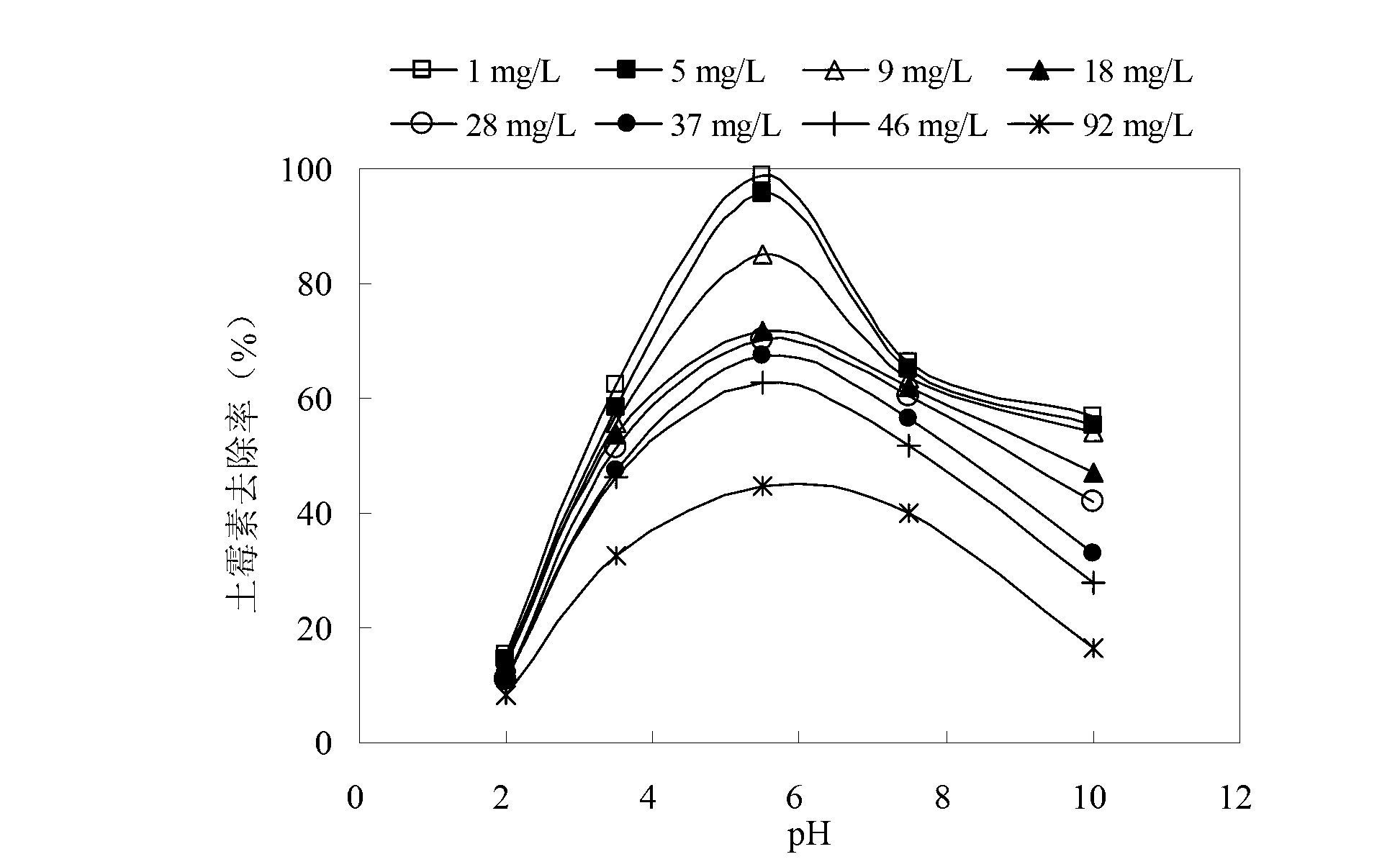

[0031] Weigh 0.2 g of biochar prepared at 300 °C and add it to 20 mL of oxytetracycline in an aqueous solution with a concentration of 1-92 mg / L at a solid-to-liquid ratio of 1:100, and adjust the pH of the system with 0.1 mol / L HCl or NaOH to 2.0, 3.5, 5.5, 7.5 and 10.0, shake at 15 rpm in the dark for 24 h at room temperature, filter with a 0.45 μm glass fiber membrane, and measure the residual concentration of oxytetracycline in the filtrate by high performance liquid chromatography (HPLC). Three replicates were set for each treatment. The result is as figure 2 It was shown that in the pH range of 3.5-10, biochar had a strong adsorption capacity for oxytetracycline, and the adsorption capacity first increased and then decreased with the increase of pH, and reached the maximum at pH 5.5. Under the optimal pH condition of pH 5.5, the adsorption and removal rate of oxytetracycline with an initial concentration of 1-92 mg / L by 300 °C biochar was 98%-45%.

[0032]

Embodiment 3

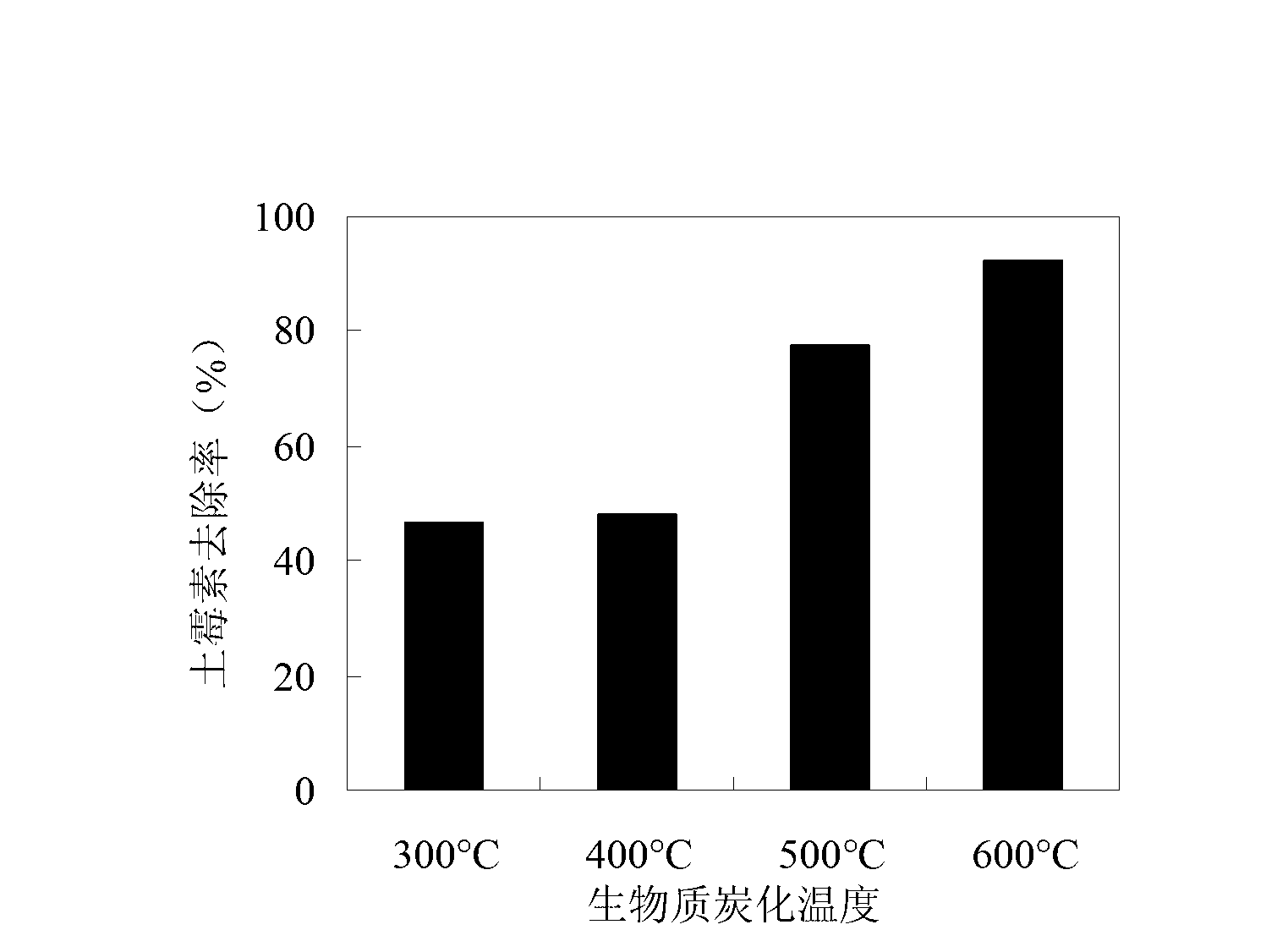

[0034] Weigh 0.2 g of 300°C, 400°C, 500°C and 600°C biochar, respectively, and add it to 20 mL of an aqueous solution with a concentration of 92 mg / L of oxytetracycline at a solid-to-liquid ratio of 1:100, and adjust with 0.1 mol / L HCl The pH of the system was 5.5, shaken at room temperature at a speed of 15 rpm in the dark for 24 h, filtered through a 0.45 μm glass fiber membrane, and the residual concentration of oxytetracycline in the filtrate was determined by high performance liquid chromatography (HPLC). repeat. The result is as image 3 As shown, as the carbonization temperature increased from 300°C to 600°C, the removal rate of oxytetracycline in water increased from 44.6% to 97.7%.

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com