Treatment method of brine waste in production process of toluene-2,4-diisocyanate (TDI)

A salt-containing wastewater, production process technology, applied in natural water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Achieve the effect of optimizing the industrial structure, solving the emission problem and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

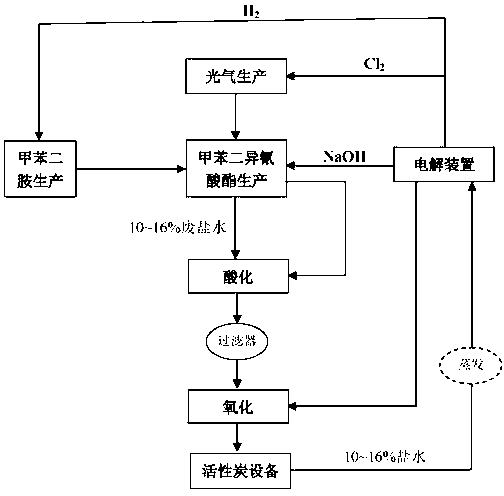

Image

Examples

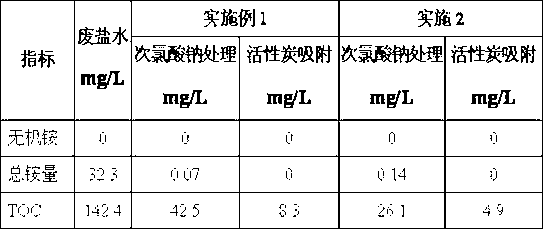

Embodiment 1

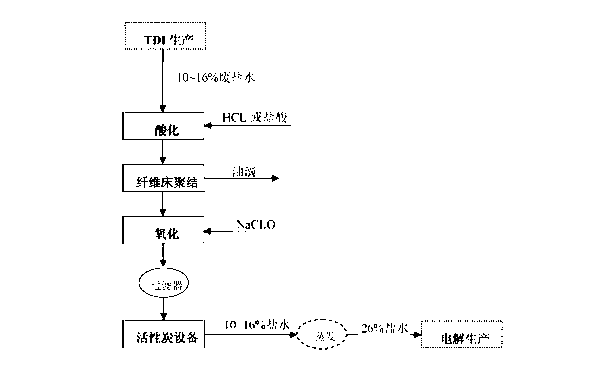

[0018] Example 1: see figure 2 , a kind of treatment method of saline waste water in TDI production process, it is characterized in that comprising the steps:

[0019] a. Neutralize the saline waste water produced in the production process of toluene diisocyanate with 12% hydrochloric acid through a pipeline mixer, adjust the pH value of the solution to 5-6, and remove carbonate;

[0020] b. Pass the waste water through the fiber bed coalescer, coalesce the small oil droplets, and lead to the static separator for separation, the residence time is 120min;

[0021] c, the water phase in the lower part of the static separator is mixed with sodium hypochlorite to react, and the reaction time is 20min;

[0022] d. Pass the oxidized waste brine through a metal filter, the filter material is 316L, and the filter element is polypropylene. After passing through the activated carbon adsorption tower, it enters the electrolysis plant salt process, and then enters the electrolysis proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com