Suspension polymerization preparation method of polystyrene/silica hydrated particle

A technology of polystyrene and suspension polymerization, which is applied in the chemical industry, can solve the problems of insufficient and effective improvement of the strength performance of polymer-inorganic composite materials, easily broken ion exchange resins, and low utilization rate of minerals, etc., to overcome poor compatibility. Poor, low price, strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

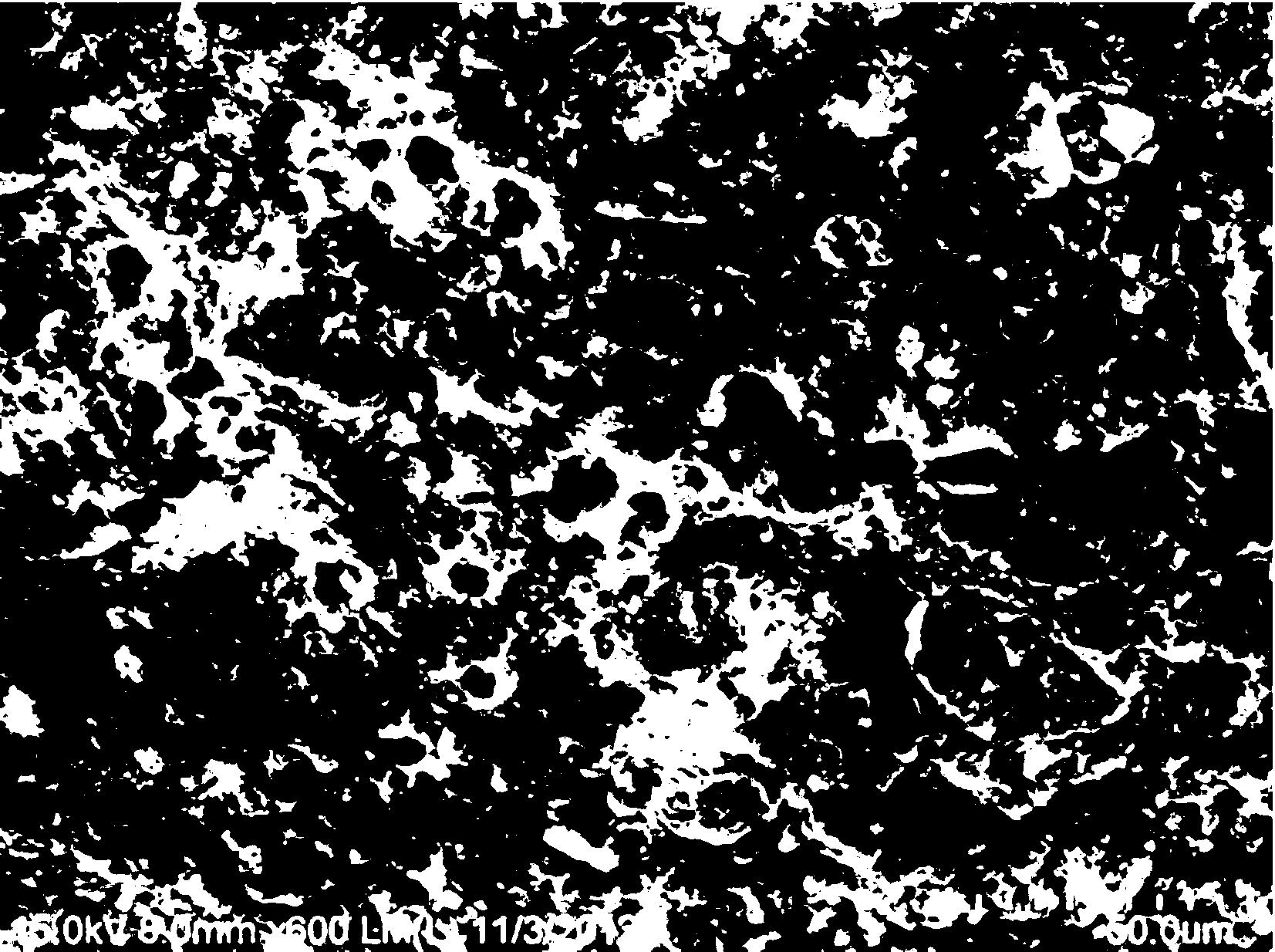

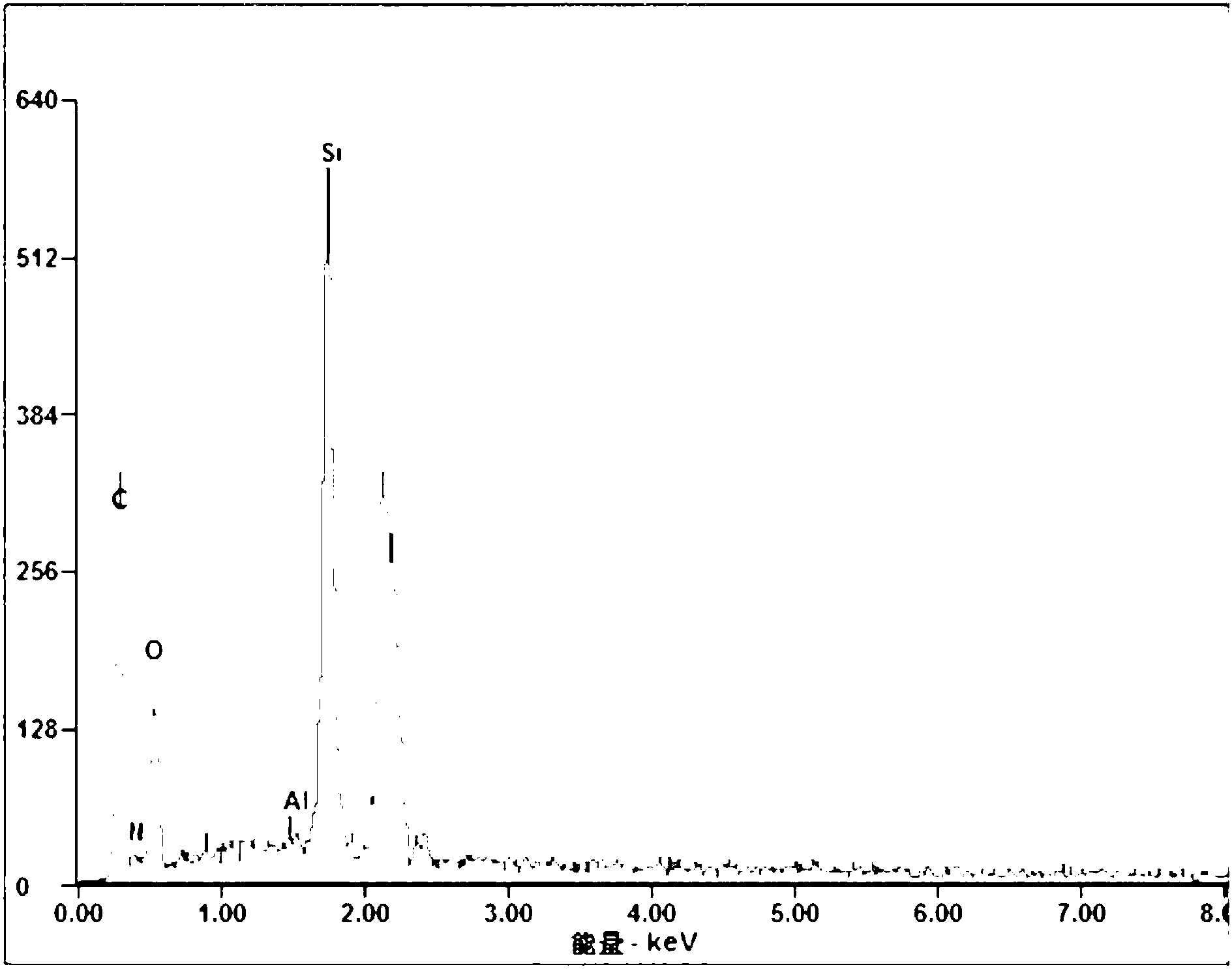

Image

Examples

Embodiment 1

[0029] A kind of suspension polymerization prepares the method for polystyrene / white carbon black particle, comprises the following steps:

[0030] (1) Surface modification of silica:

[0031] (a) Weigh 10.00g of white carbon black and pour it into a dry 250ml three-necked bottle, add 100ml of 95% ethanol to it, start the stirrer, stir well, and weigh 0.50g of γ-glycidyl etheroxypropyl trimethoxysilane Pour into the above-mentioned three-neck flask, heat up to 80°C and reflux for 2 hours, then cool to room temperature, stop stirring, pour the product into a clean beaker, wash with absolute ethanol 3 times, and dry;

[0032] (b) Weigh 10.00g of the solid product in step (a) and pour it into a dry 250ml three-necked bottle, weigh 0.20g of stearic acid and dissolve it in 100ml of toluene and pour it into the above-mentioned three-necked bottle, start the stirrer, and heat to 60°C After reflux for 2 hours, cool to room temperature and centrifuge, wash the product with absolute et...

Embodiment 2

[0040] A kind of suspension polymerization prepares the method for polystyrene / white carbon black particle, comprises the following steps:

[0041] (1) Surface modification of silica:

[0042](a) Weigh 10.00g of white carbon black and pour it into a dry 250ml three-neck bottle, add 100ml of 95% ethanol to it, start the stirrer, stir well, weigh 0.50g of γ-aminopropyltriethoxysilane and pour it into In the above three-neck flask, heat up to 85°C and reflux for 2.5 hours, then cool to room temperature, stop stirring, pour the product into a clean beaker, wash with absolute ethanol 3 times, and dry;

[0043] (b) Weigh 10.00g of the solid product in step (a) and pour it into a dry 250ml three-necked bottle, weigh 0.10g of stearic acid and dissolve it in 100ml of toluene and pour it into the above-mentioned three-necked bottle, start the stirrer, and heat to 65°C After reflux for 2.5 hours, cool to room temperature and centrifuge, wash the product with absolute ethanol for 3 times...

Embodiment 3

[0050] A kind of suspension polymerization prepares the method for polystyrene / white carbon black particle, comprises the following steps:

[0051] (1) Surface modification of silica:

[0052] (a) Weigh 10.00g of white carbon black and pour it into a dry 250ml three-necked bottle, add 100ml of 95% ethanol to it, start the stirrer, stir well, and weigh 0.50g of γ-methacryloxypropyl trimethoxy Pour the base silane into the above-mentioned three-necked flask, heat up to 90°C and reflux for 3 hours, then cool to room temperature, stop stirring, pour the product into a clean beaker, wash with absolute ethanol 3 times, and dry;

[0053] (b) Weigh 10.00g of the solid product in step (a) and pour it into a dry 250ml three-necked bottle, weigh 0.30g of stearic acid and dissolve it in 100ml of toluene and pour it into the above-mentioned three-necked bottle, start the stirrer, and heat to 70°C After refluxing for 3 hours, cool to room temperature and centrifuge, the product is washed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com