Preparation method of cross-linking sodium carboxymethylcellulose pharmaceutical adjuvant

A technology of sodium carboxymethyl cellulose and cross-linked carboxymethyl, which is applied in the field of preparation of cross-linked sodium carboxymethyl cellulose pharmaceutical excipients, can solve the problem of lack of regulation and control of the degree of substitution of cross-linked sodium carboxymethyl cellulose. Conformity and other problems, to achieve the effect of mild reaction solvent, avoid hydrolysis, and controllable cross-linking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

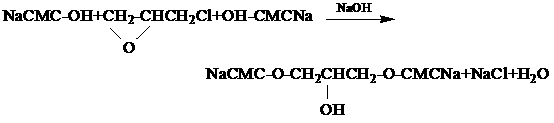

Method used

Image

Examples

Embodiment 1

[0025] In a 250ml round bottom flask equipped with a condenser tube and a thermometer, add 67g of ethanol 75wt% as a dispersant, start stirring, then slowly add 10g of sodium carboxymethylcellulose with a degree of substitution of 0.80, after the addition is complete, to obtain The ethanol dispersion of sodium carboxymethyl cellulose is then heated to 40°C, and the pH value of the system is adjusted to 13 with 20wt% sodium hydroxide solution, and the stirring is continued for 30 minutes until the system is uniformly dispersed, and then the mass fraction is added dropwise while stirring It is 5 g of 20% epichlorohydrin ethanol solution, and the temperature is kept at 40 ° C, and the reaction is stirred for 5.5 h. After the reaction, neutralize to neutral with 36wt% acetic acid, and filter with suction. The suction-filtered product was washed twice with 75 wt% ethanol, suction-filtered, dried at 65°C, pulverized, and sieved to obtain croscarmellose sodium powder.

Embodiment 2

[0027] In a 250ml round bottom flask equipped with a condenser tube and a thermometer, add 67g of ethanol 75wt% as a dispersant, start stirring, then slowly add 10g of sodium carboxymethylcellulose with a degree of substitution of 0.80, after the addition is complete, to obtain Ethanol dispersion of sodium carboxymethyl cellulose, then warm up to 40°C, adjust the pH value of the system to 13 with sodium hydroxide solution, continue stirring for 30 minutes until the system is evenly dispersed, then add dropwise with a mass fraction of 20% while stirring The ethanol solution of epichlorohydrin was 6 g, the temperature was kept at 40° C., and the reaction was stirred for 5.5 h. After the reaction, neutralize to neutral with acetic acid, and filter with suction. The suction-filtered product was washed twice with ethanol aqueous solution, suction-filtered, dried at 90°C, pulverized, and sieved to obtain croscarmellose sodium powder.

Embodiment 3

[0028] Embodiment 3 is basically the same as Embodiment 1, but has the following changes:

[0029] Described dispersion agent is isopropanol aqueous solution, and wherein the massfraction of isopropanol is 55%, and the mass ratio of the quality of sodium carboxymethyl cellulose and isopropanol aqueous solution is 1:4;

[0030] Described basic catalyst is potassium hydroxide;

[0031] The massfraction that is added dropwise is the quality of the ethanol solution of 40% epichlorohydrin is 4g;

[0032] The mass fraction of the aqueous ethanol solution used for washing is 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com