Nanometer emulsion type water control fracturing fluid for tight gas reservation well and preparation method thereof

A nano-emulsion and hydraulic fracturing technology, applied in chemical instruments and methods, earth-moving drilling, wellbore/well components, etc., can solve the problems of large particle size of polymer cross-linked system, easy blockage of gas flow channels, and high injection pressure , to achieve the effect of reducing water permeability, obvious water control effect and low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

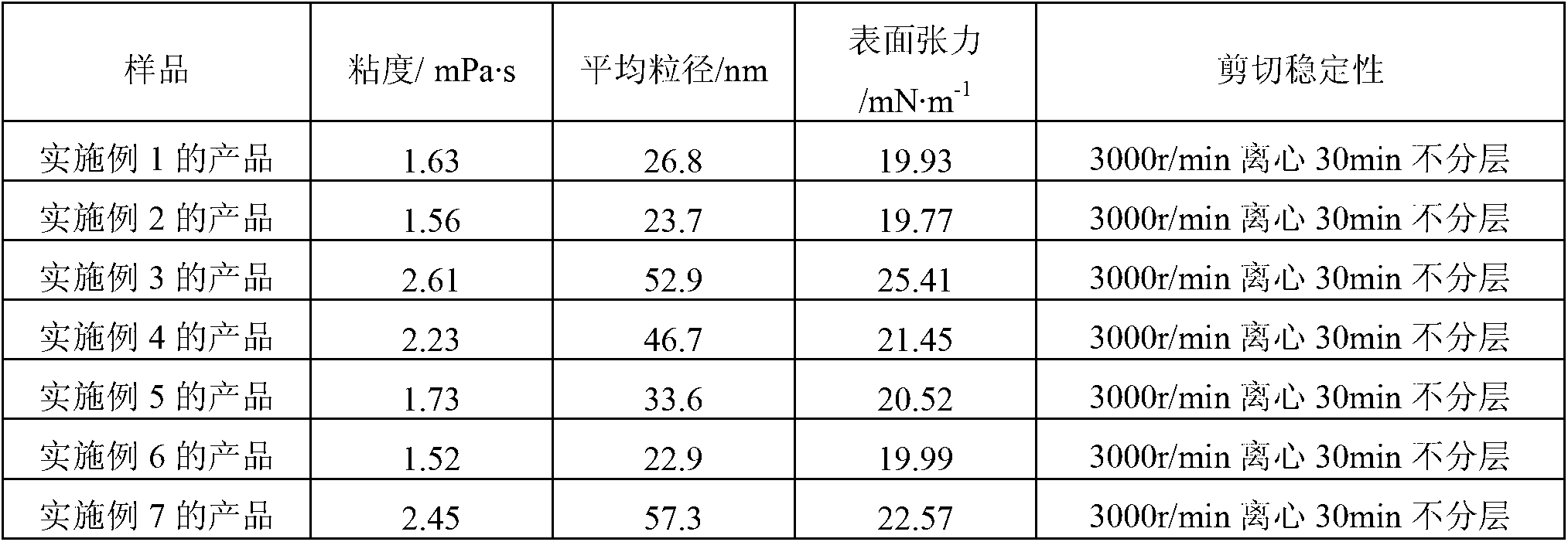

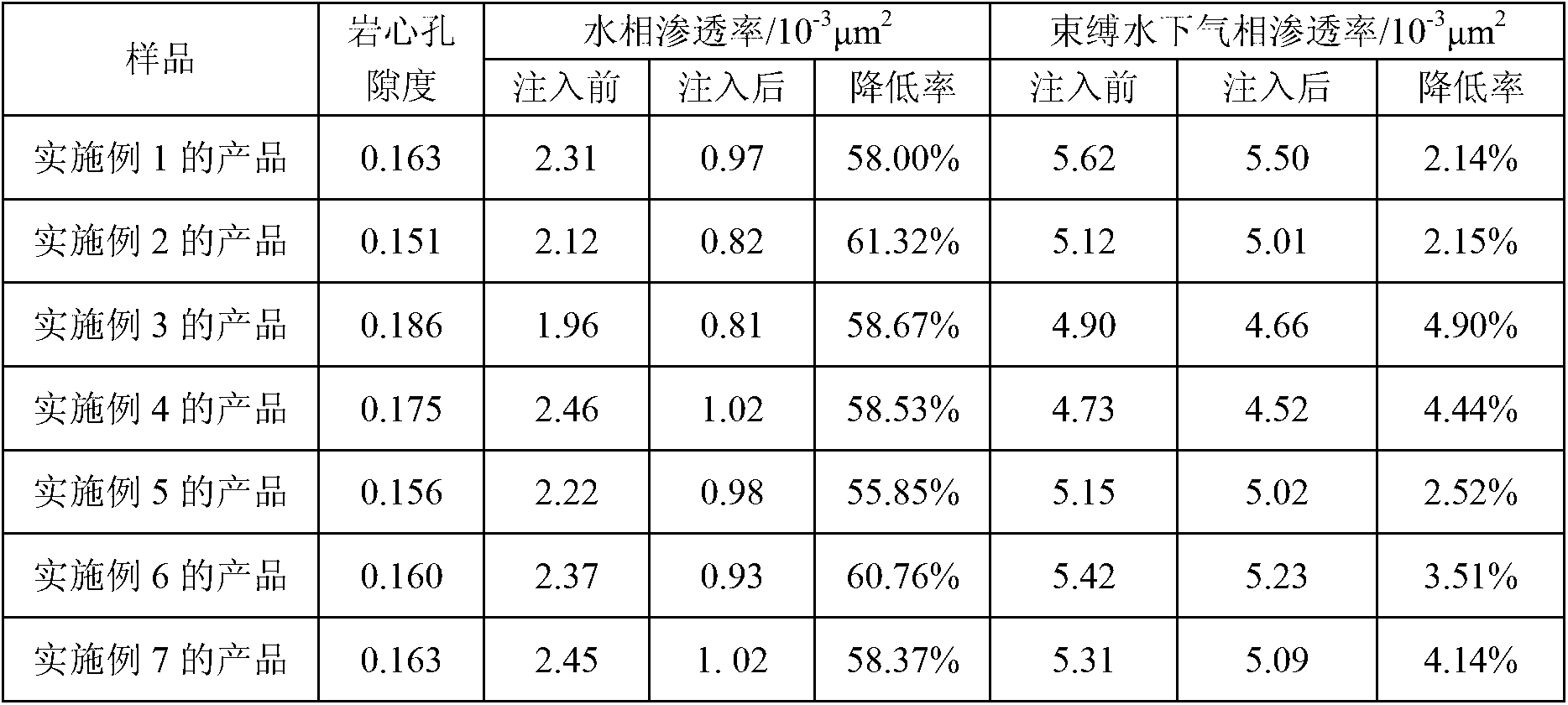

Embodiment 1

[0036] a. At room temperature, add 20g sodium dodecyl sulfate (SDS) and 11g n-butanol to 50g amino silicone oil (ammonia value 0.6), mix in a 250mL beaker, stir at 250r / min for 20min, then add 0.5 g acetic acid and 50 mL deionized water, continue to stir for 30 minutes, add 6 g of NaCl and 50 mL of deionized water, and continue to stir for about 10 minutes to a homogeneous phase to obtain an amino silicone oil nanoemulsion.

[0037] b. Add 0.3-0.5 parts of amino silicone oil nanoemulsion to 100 parts of water and mix them evenly to obtain a homogeneous transparent blue-blue liquid, which is a nanoemulsion type water-control fracturing fluid.

[0038] figure 1 This is an electron micrograph of the nanoemulsion type water-control fracturing fluid prepared in Example 1. The figure shows that the particle size of the product is relatively uniform, and the particle size is about 20nm-30nm.

Embodiment 2

[0040] a. At room temperature, add 15g fatty alcohol polyoxyethylene ether (AEO-9) and 12g n-butanol to 50g amino silicone oil (ammonia value 0.3), put them in a 250mL beaker and mix, stir at 200r / min for 20min, then Add 0.35g of acetic acid and 50mL of deionized water, continue to stir for 30min, add 5g of NaCl and 50mL of deionized water, continue to stir for about 10min until homogeneous, to obtain amino silicone oil nanoemulsion.

[0041] b. Add 0.3-0.5 parts of amino silicone oil nanoemulsion to 100 parts of water and mix them evenly to obtain a homogeneous transparent blue-blue liquid, which is a nanoemulsion type water-control fracturing fluid.

Embodiment 3

[0043] a. At room temperature, add 15g octylphenol polyoxyethylene ether (OP-10) and 12g n-butanol to 50g amino silicone oil (ammonia value 0.3), put them into a 250mL beaker and mix, stir at 150r / min for 25min, Then add 0.4g of acetic acid and 50mL of deionized water, continue to stir for 30 minutes, add 5g of NaCl and 50mL of deionized water, continue to stir for about 10 minutes to homogeneity, and obtain a viscous liquid with more white bubbles, and let it stand until the bubbles disappear. Amino silicone oil nanoemulsion.

[0044] b. Take 0.3-0.5 parts of amino silicone oil nanoemulsion into 100 parts of water and mix evenly to obtain a homogeneous transparent blue-blue liquid, which is a nanoemulsion type water-control fracturing fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com