A device, method and application for removing free acid in ester synthetic oil

A technology of ester synthetic oil and free acid, applied in ion exchange treatment device, ion exchange, refined hydrocarbon oil and other directions, can solve the problems of environmental pollution of soap stock, low yield of acid removal process, etc., to reduce pollution and yield High, simple post-processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

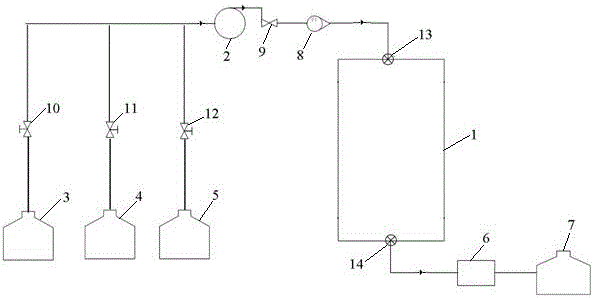

[0060] A kind of pentaerythritol polyol ester oil purchased from the market, the acid value of the oil product is 3mgKOH / g, the color is brownish yellow, and the chroma is 1.5 (test method GB / T6540). After mixing 1L of petroleum ether and 2L of ethanol, add 2L of oil product and mix it into oil product tank 5. Add 5L resin ① to resin tank 1. Open the third valve 12 and the fourth valve 9, the pump 2 and the flow meter 8, so that the diluted liquid of the oil enters the resin tank 1 and contacts with the resin ①, and the flow rate is controlled by the flow meter 8 and the pump 2 to be 0.6L / h. After a short initial period, a clear and transparent solution emerges from the resin tank. The chroma of the oil after removing the solvent is 0.5, the acid value of the oil is 0.01mgKOH / g, and the nitrogen content of the oil is 0.83mg / L (test method SH / T0657-2007). The final product can be used in internal combustion engine oil, compressor oil, bearing oil, high temperature chain oil a...

Embodiment 2

[0062] A trimethylolpropane polyol ester oil purchased from the market has an acid value of 1 mgKOH / g, a light yellow color, and a chroma of 1.0 (test method GB / T6540). After mixing 1L of ethyl acetate and 2L of ethanol, add 2L of oil and mix it into oil tank 5. Add 5L of resin ② into the resin tank 1. Open the third valve 12 and the fourth valve 9, the pump 2 and the flow meter 8, so that the diluted liquid of the oil enters the resin tank 1 and contacts with the resin ②, and the flow rate is controlled by the flow meter 8 and the pump 2 to 0.6L / h. Collect the product, the chroma of the oil product after removing the solvent is 0.5, the acid value of the oil product is 0.025mgKOH / g, and the nitrogen content of the oil product is 1mg / L (test method SH / T0657-2007). The products can be used in internal combustion engine oil, compressor oil, bearing oil, high temperature chain oil and other fields. The elution of free acid in the subsequent resin and the regeneration of the res...

Embodiment 3

[0064] A kind of pentaerythritol polyol ester oil purchased from the market, the acid value of the oil product is 2mgKOH / g, the color is light yellow, and the chromaticity is 1.0 (test method GB / T6540). Add 2L of oil to oil tank 5. Add 4L of resin into resin tank 1 ③. Open the third valve 12 and the fourth valve 9, the pump 2 and the flow meter 8, so that the oil slowly enters the resin tank 1 and contacts with the resin ③, and the flow rate is controlled by the flow meter 8 and the pump 2 to be 0.3L / h. Collect the product, the color of the collected oil is 0.5, the acid value of the oil is 0.015mgKOH / g, and the nitrogen content of the oil is 0.9mg / L (test method SH / T0657-2007). The products can be used in internal combustion engine oil, compressor oil, bearing oil, high temperature chain oil and other fields. The elution of free acid in the subsequent resin and the regeneration of the resin are the same as in Example 1.

[0065] Table 2, the performance index comparison of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com