Method for producing copper bar alloy material by horizontal continuous casting production of scrap copper

A technology of horizontal continuous casting and alloy materials, applied in the direction of improving process efficiency, etc., can solve the problems of destroying the natural environment, high raw material costs, and increasing production costs, and achieve the effects of short process flow, optimized performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The method for producing copper rod alloy materials by horizontal continuous casting of waste miscellaneous copper according to the present invention includes waste miscellaneous copper material selection, batching, feeding smelting and refining, sampling inspection, horizontal continuous casting, sawing and testing finished products,

[0020] According to the material size and shape, the waste miscellaneous copper materials can be divided into filamentary, granular and irregular. Filiform and granular scrap copper comes from brass shavings from copper product processing companies, and irregular scrap copper comes from copper parts of waste electrical appliances. Irregular miscellaneous copper scraps pass through the magnetic separator 3 times, and filamentary and granular scrap miscellaneous coppers pass through the magnetic separator 6 times to select materials with high iron content to avoid excessive iron elements during smelting. Rod insertion inspection, each time...

Embodiment 2

[0027] According to the material size and shape, the scrap copper materials purchased are divided into filamentary, granular and irregular. Take filiform and granular waste miscellaneous copper and pass it through the magnetic separator 5 times, and irregular waste miscellaneous copper through the magnetic separator 2 times. After the material selection is completed, insert the magnetic rod for inspection. Each time the magnetic rod absorbs less than 1g, it is regarded as a qualified raw material ,

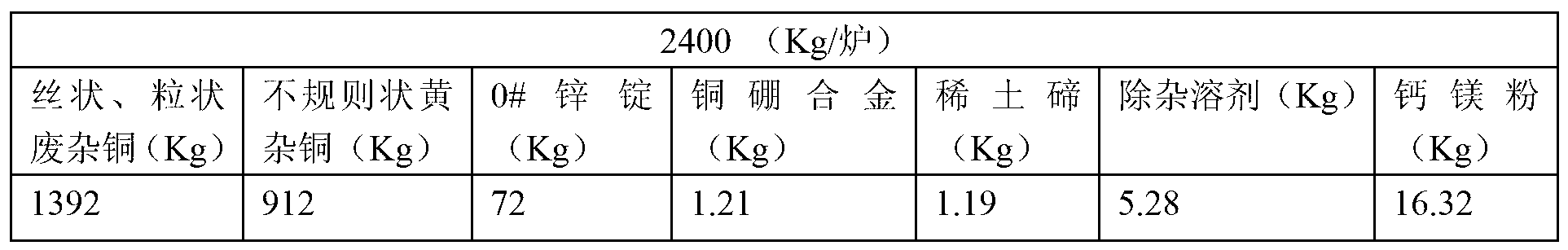

[0028] Prepare scrap copper, zinc ingot and additive combination according to the following ratio:

[0029]

[0030] The specific ingredients of impurity removal solvent are as follows

Cryolite (Kg)

Borax (Kg)

NaCl (Kg)

CaCO 3 (Kg)

MgCO 3 (Kg)

0.74

1.59

0.74

0.74

0.8

0.67

[0032] Put filamentary and granular waste copper together with boron alloy and impurity removal solvent into...

Embodiment 3

[0036] According to the material size and shape, the scrap copper materials purchased are divided into filamentary, granular and irregular. Take filiform and granular waste miscellaneous copper and pass it through the magnetic separator 4 times, and irregular waste miscellaneous copper through the magnetic separator 1 time. After the material selection is completed, insert the magnetic rod for inspection. Each time the magnetic rod absorbs less than 1g, it is regarded as a qualified raw material ,

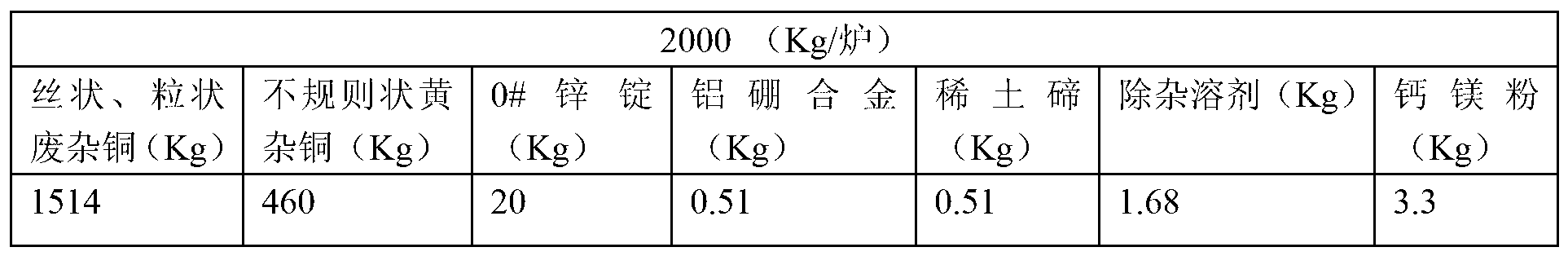

[0037] Prepare scrap copper, zinc ingot and additive combination according to the following ratio:

[0038]

[0039] The specific ingredients of impurity removal solvent are as follows

Cryolite (Kg)

Borax (Kg)

NaCl (Kg)

CaCO 3 (Kg)

MgCO 3 (Kg)

0.3

0.6

0.3

0.3

0.09

0.09

[0041] Put filamentary and granular waste copper together with boron alloy and impurity removal solvent into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com