System device for drying lignite by superheated steam

A technology of superheated steam and system installation, which is applied in the direction of drying gas arrangement, heating to dry solid materials, drying solid materials, etc. Economic and environmental benefits, improved drying quality and calorific value content, improved energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

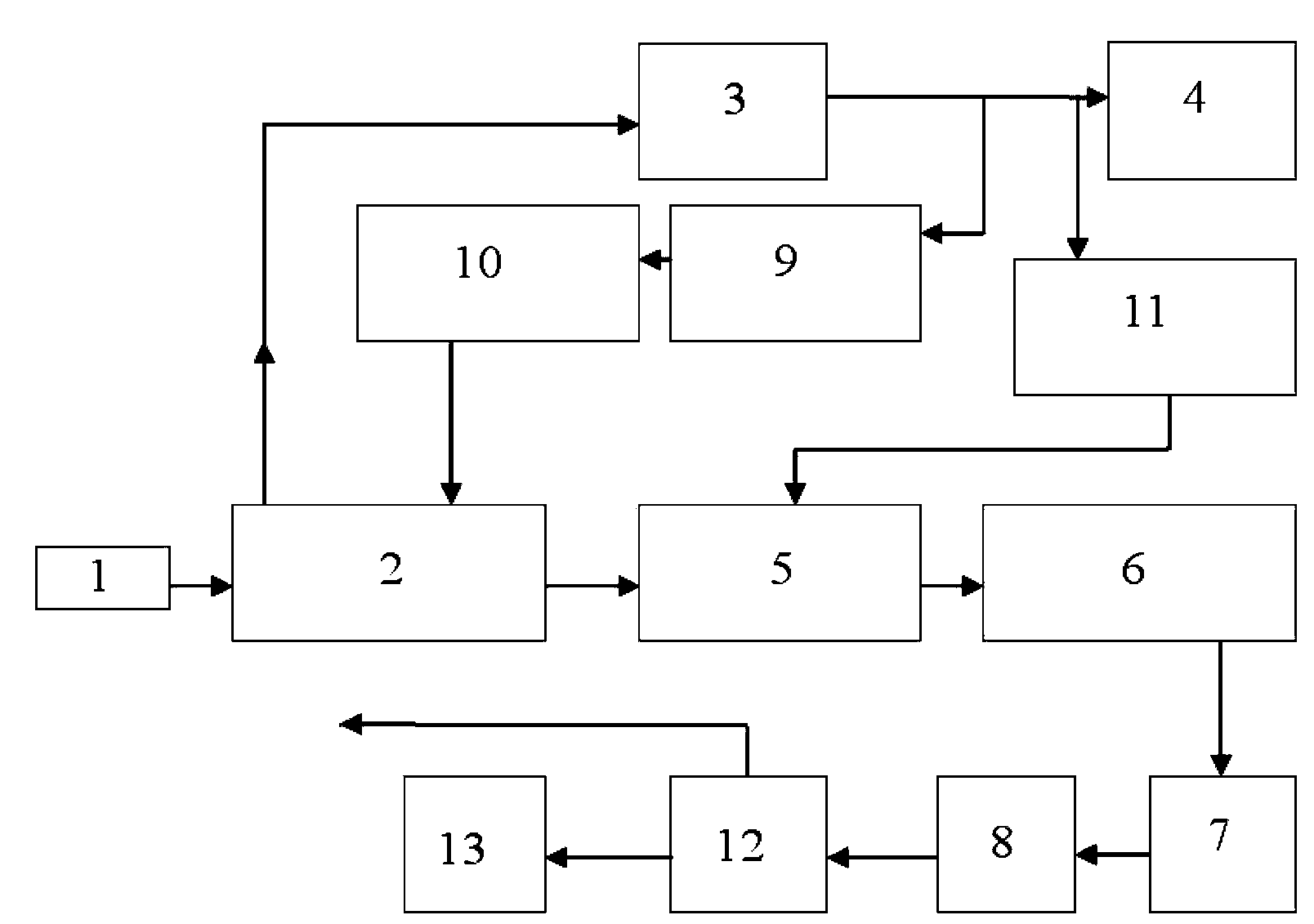

[0015] The principle and system structure of the present invention will be further described below in conjunction with the accompanying drawings and through embodiments. It should be noted that this embodiment is descriptive rather than restrictive, and the protection scope of the present invention is not limited by this embodiment.

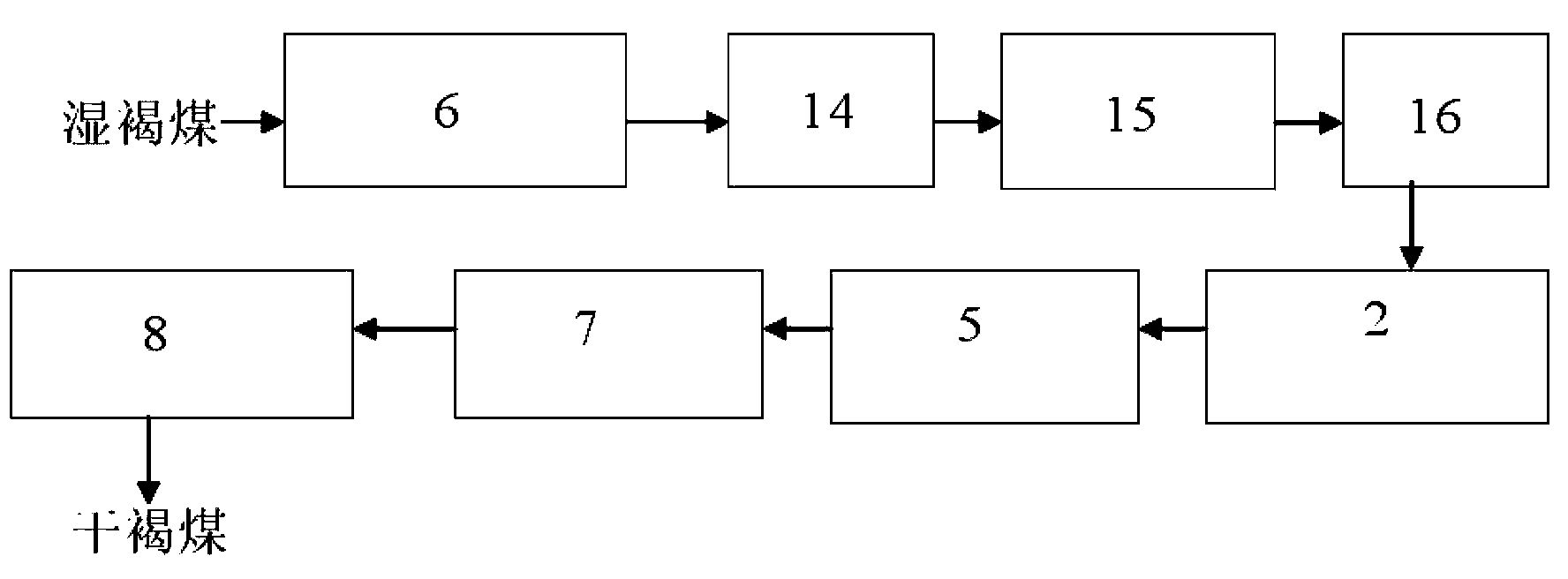

[0016] A system device for drying lignite with superheated steam, the system structure is as follows: superheated steam pipe 1 is connected to fluidized bed 2, and the hot steam is divided into two paths after flowing through the fluidized bed: one path is connected in series to the electrostatic precipitator 3 and The safety door 4; the other road is connected in series with the inlets of the main heat exchanger group 5 and the secondary heat exchanger group 6 in sequence. The outlet of the secondary heat exchanger group is connected in series with the first cooler 7 and the second cooler 8 through pipelines, and the end of the second cooler is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com