Synthetic method of transition metal sulfide

A transition metal and synthesis method technology, applied in the field of direct preparation of transition metal sulfides, can solve the problems of environmental pollution by waste discharge, high reaction cost, difficulty in large-scale industrial production, etc., achieve environmental friendliness, simple synthesis process, and low equipment requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

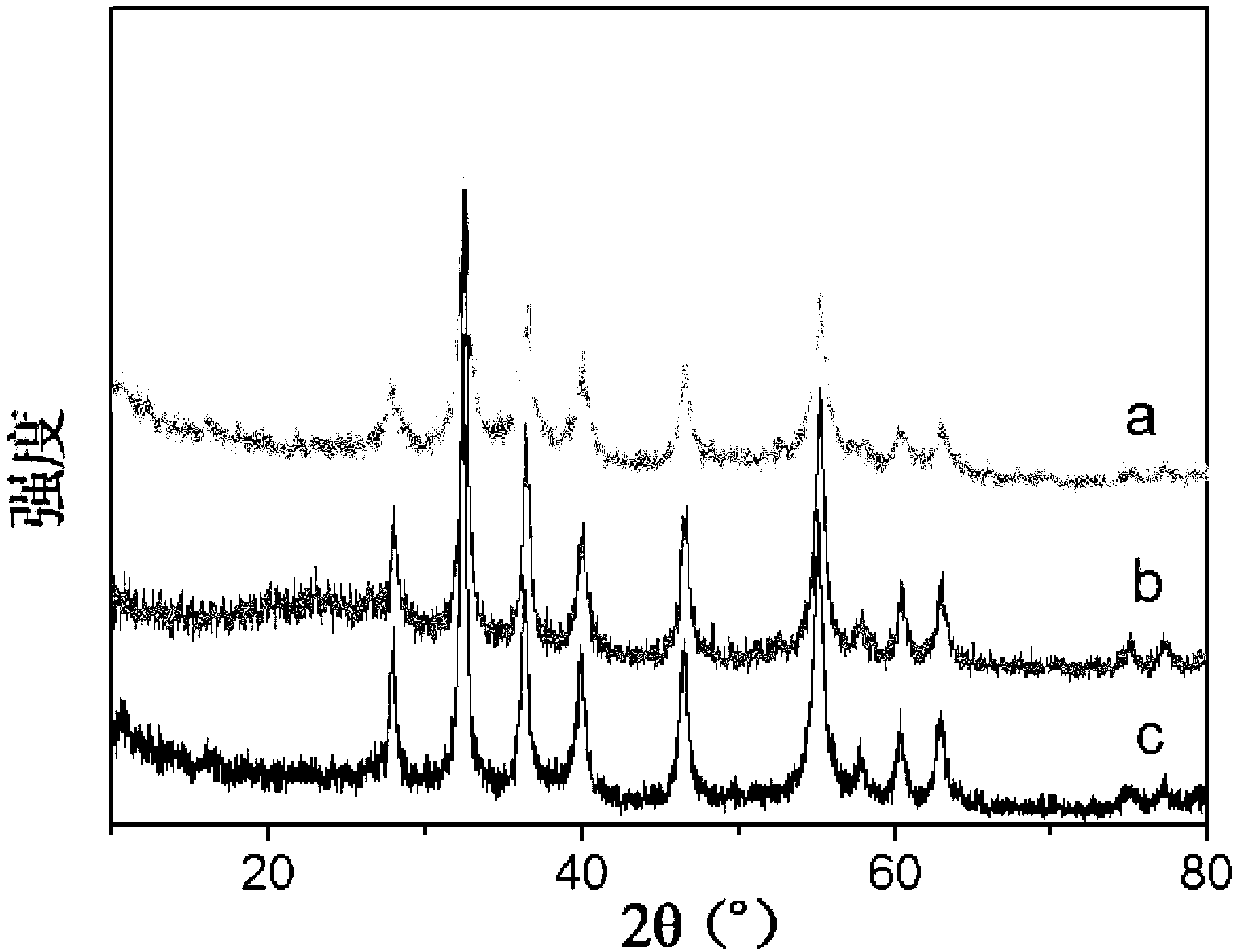

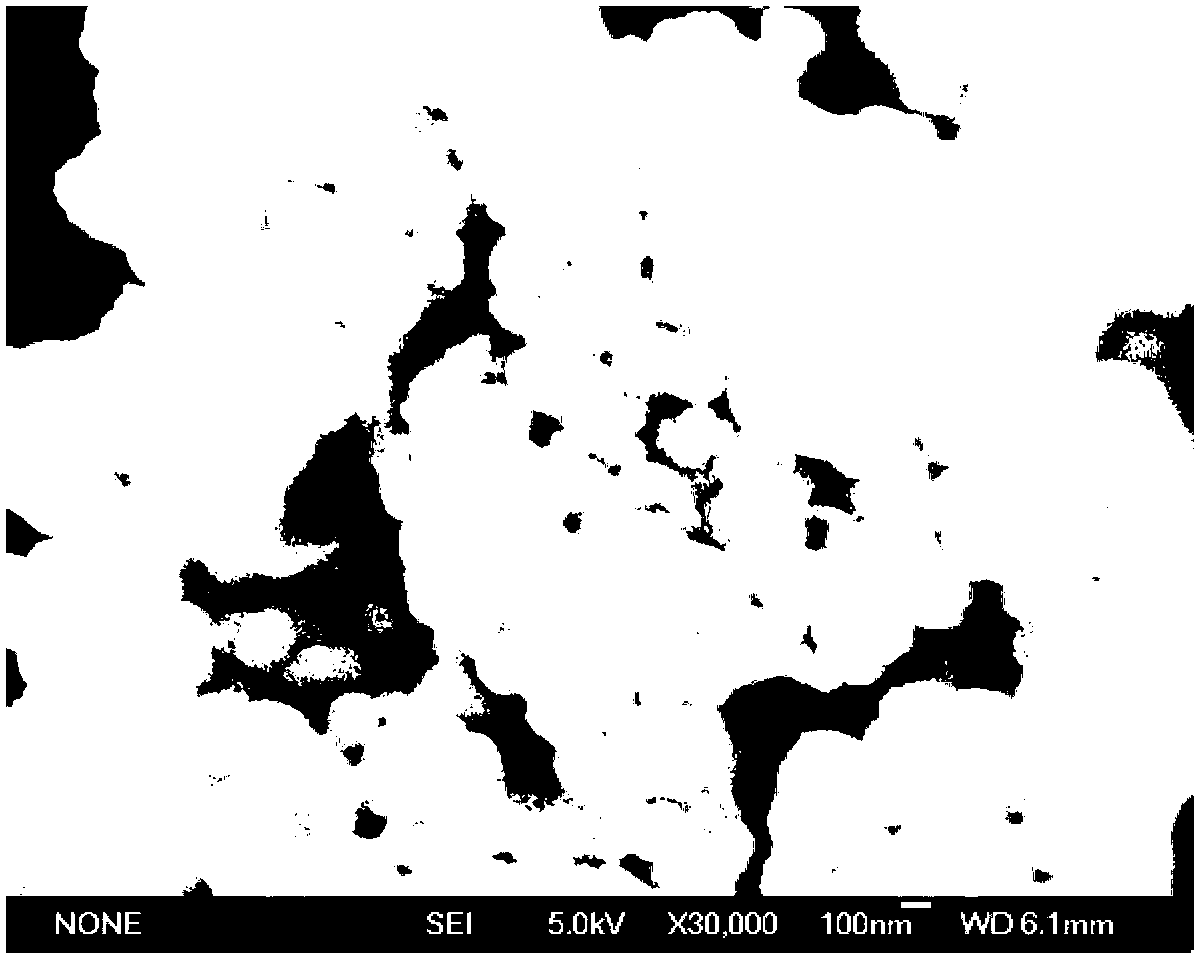

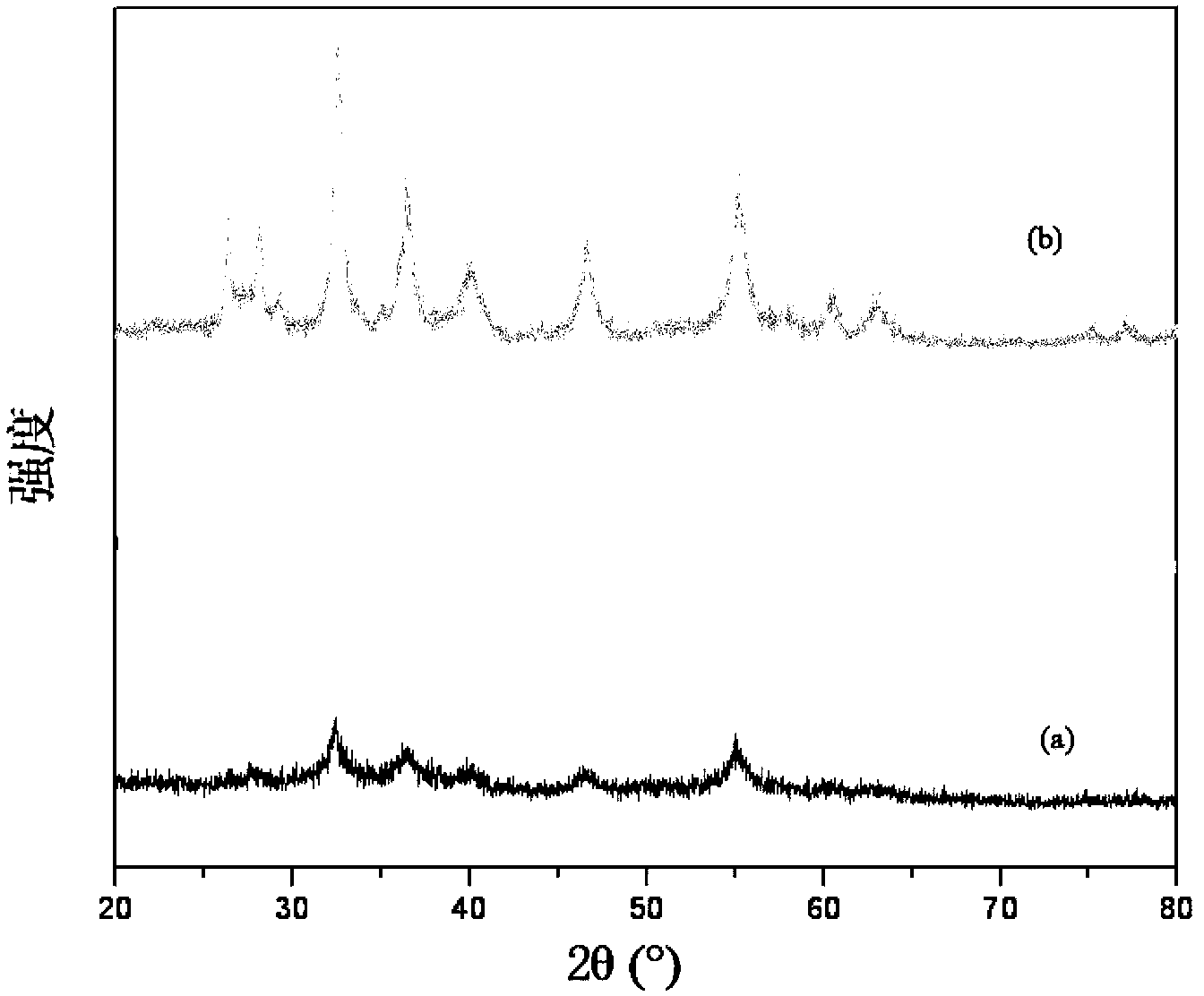

[0024] Mix 0.30g of cobalt nitrate hexahydrate with 0.42g of thiourea (cobalt, sulfur molar ratio 1:5), put it into a reaction vessel, react at 180°C for 4 hours, take it out and cool to room temperature, wash and filter. A black cobalt disulfide powder is obtained. Its X-ray diffraction pattern (XRD) is as figure 1 As shown in (a), its scanning electron microscope (SEM) is as follows figure 2 shown.

Embodiment 2

[0026] Mix 0.30g of cobalt nitrate hexahydrate with 0.42g of thiourea (cobalt, sulfur molar ratio 1:5), put it into a reaction vessel, react at 180°C for 12 hours, take it out and cool to room temperature, wash and filter. A black cobalt disulfide powder is obtained. Its X-ray diffraction pattern (XRD) is as figure 1 (b) shown.

Embodiment 3

[0028] Mix 0.30g of cobalt nitrate hexahydrate with 0.42g of thiourea (cobalt, sulfur molar ratio 1:5), put it into a reaction vessel, react at 180°C for 24 hours, take it out and cool to room temperature, wash and filter. A black cobalt disulfide powder is obtained. Its X-ray diffraction pattern (XRD) is as figure 1 (c) shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com