Novel wall material and preparation technology thereof

A wall material and preparation technology, applied in the field of building materials, can solve problems such as environmental pollution, large water consumption, and environmental damage, and achieve the effects of reducing costs, protecting the environment, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Separately crush construction waste, fly ash and paper mill sludge in a cone mill, and make the fineness 150-300 mesh;

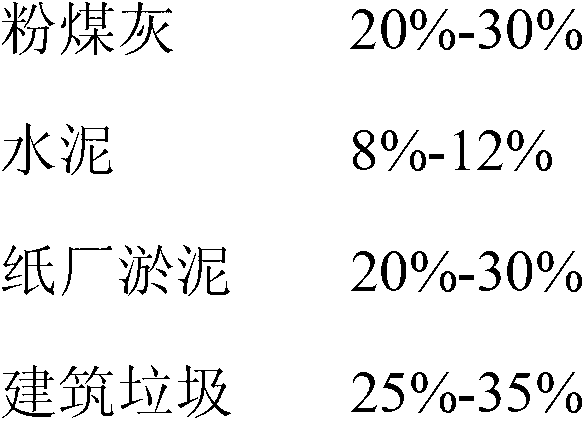

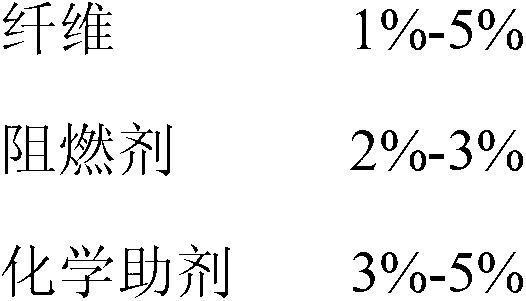

[0031] (2) Add crushed construction waste, fly ash and paper mill sludge, cement, fiber and flame retardant into the mixer and mix them. The content of each component is:

[0032]

[0033] Moreover, in this embodiment, the flame retardant is inorganic aluminum hydroxide flame retardant, and the fiber is polypropylene. Except for paper mill sludge and construction waste, the rest of the components are purchased from the market.

[0034] (3) Add chemical additives to the above mixture, and enter the foaming machine for foaming treatment. The chemical additives are: 2Kg of water-repellent agent, 2.5Kg of foaming agent, and the water-repellent agent is silicone water-repellent agent. The foaming agent is a composite foaming agent;

[0035] (4) After foaming, the molded block is obtained by hydraulic extrusion molding of a hydraulic pressure moldin...

Embodiment 2

[0038] This embodiment adopts the same operation process as in Example 1 to obtain finished product 2. The difference between this embodiment and Example 1 is the proportioning of components. The proportioning of each component in this embodiment is

[0039]

[0040] Among them, the chemical additives are: 2.5Kg of water-repellent agent and 2.5Kg of foaming agent.

Embodiment 3

[0042] This embodiment adopts the same operation process as in Example 1 to obtain finished product 3. The difference between this embodiment and Example 1 is the proportioning of components. The proportioning of each component in this embodiment is

[0043]

[0044] Among them, the chemical additives are: water-repellent agent 1.5Kg, foaming agent 1.5Kg.

[0045] We will get the finished product 1 for performance testing and get the following experimental data:

[0046] 1. Wind load resistance: The finished product 1 is made into an insulation board system, and then the test wind load value is increased to 10kpa. The sample system has no insulation board fracture, and there is no delamination in the insulation board or between the insulation board and its protective layer. The protective layer is detached, the insulation board is pulled out from the fixture, the mechanical fastener is pulled out from the base, the insulation board is detached from the supporting structure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com