Phenyl phosphonic acid rare-earth salt compounded system flame-retardant glass fiber enhanced PET material and preparation method thereof

A technology of polyethylene terephthalate and polyethylene terephthalate, which is applied to the flame-retardant glass fiber reinforced polyethylene terephthalate material of phenylphosphonic acid rare earth salt compound system and the same In the field of preparation, it can solve the problems of weakened dominant position and toxicity, and achieve the effect of obvious effect, simple and easy processing method, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] Embodiment formula is as follows:

[0044] (2) In this example, the rare earth element lanthanum (La) was used as an example to synthesize lanthanum phenylphosphonate (LaPP). : (1) 8mmol phenylphosphonic acid (H 2 o 3 PC 6 h 5 ,) Dissolve in 100mL ethanol / water mixed solvent (volume ratio of ethanol / water 1:1) to obtain phenylphosphonic acid solution, and then place the obtained solution in a 250mL three-necked bottle;

[0045] (2) Take 8mmol ReCl 3 ·6H 2 O was dissolved in 75mL of deionized water and added to the phenylphosphonic acid solution in step (1), stirred, adjusted to pH 6 with 0.1mol / L NaOH solution, stirred and refluxed at 70-80°C for 22 hours to obtain white suspension;

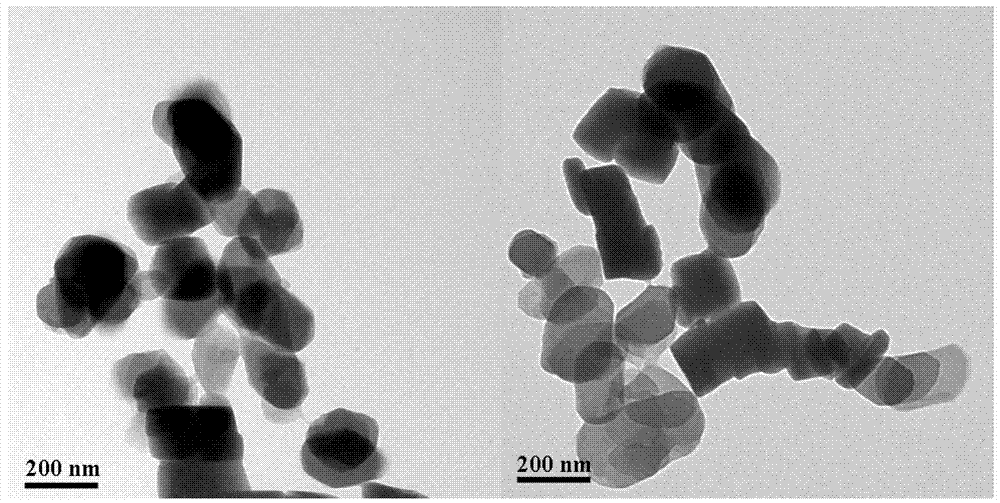

[0046] (3) Suction filter the white suspension obtained in step (2), wash with deionized water, filter, and dry at 80° C. to constant weight to obtain a layered lanthanum phenylphosphonate nanolayer material.

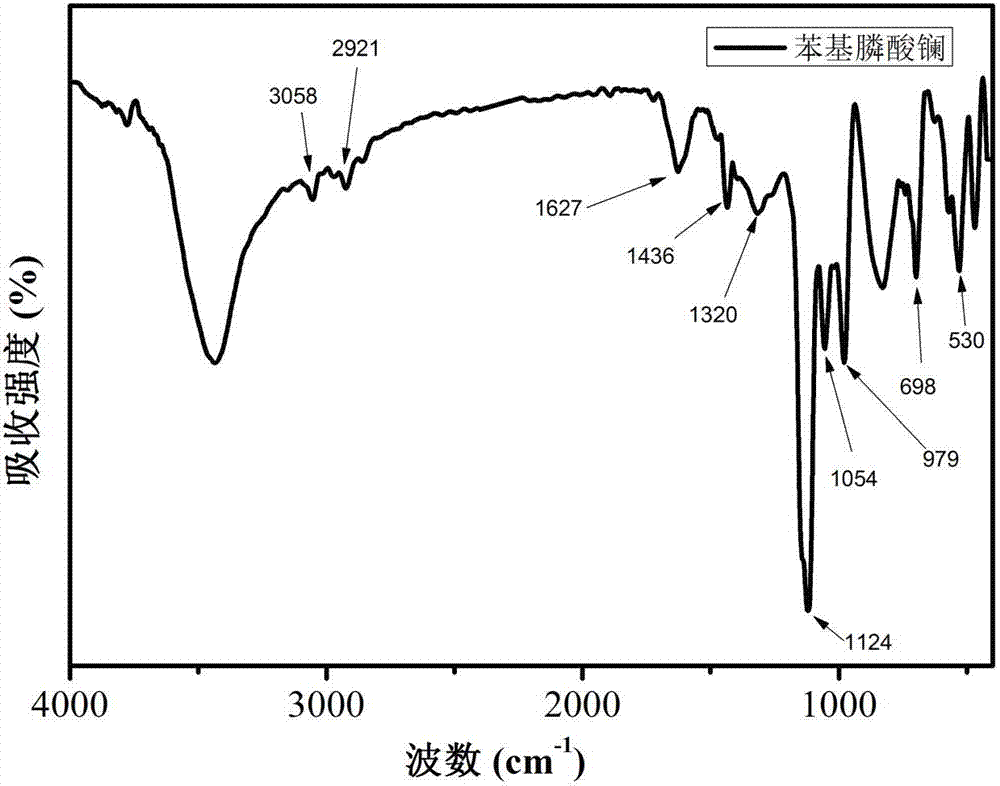

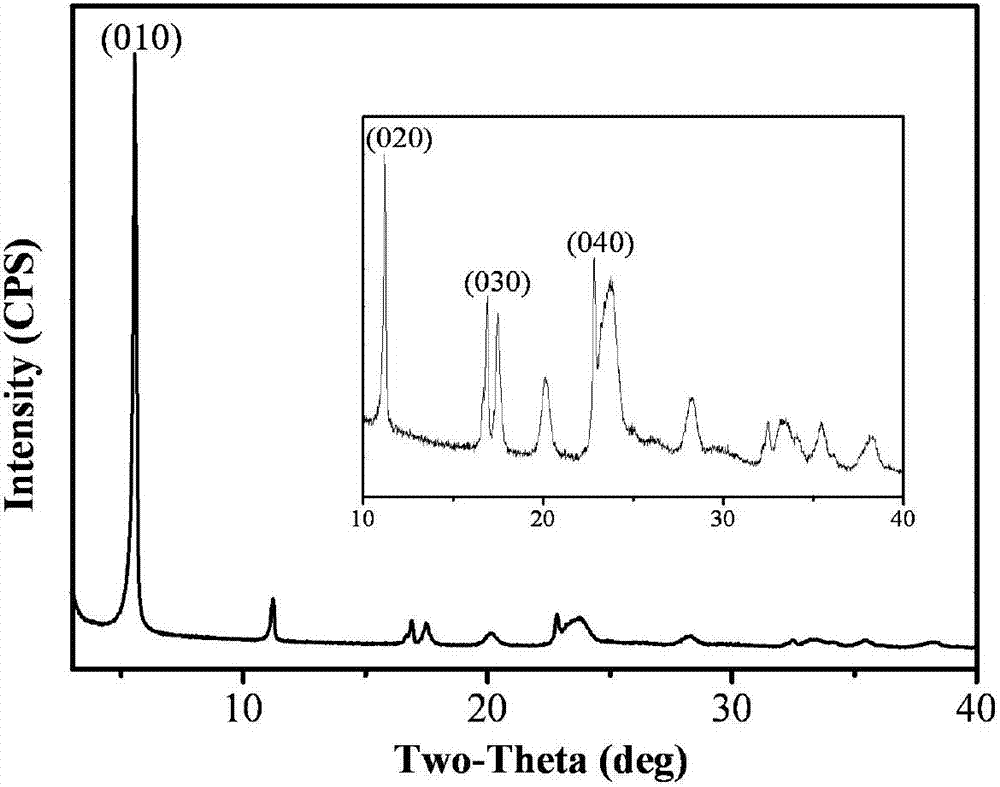

[0047] Synthetic lanthanum phenylphosphonate infrared spectrum, transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com