Porous hydroxyapatite flower-like microspheres and preparation method thereof

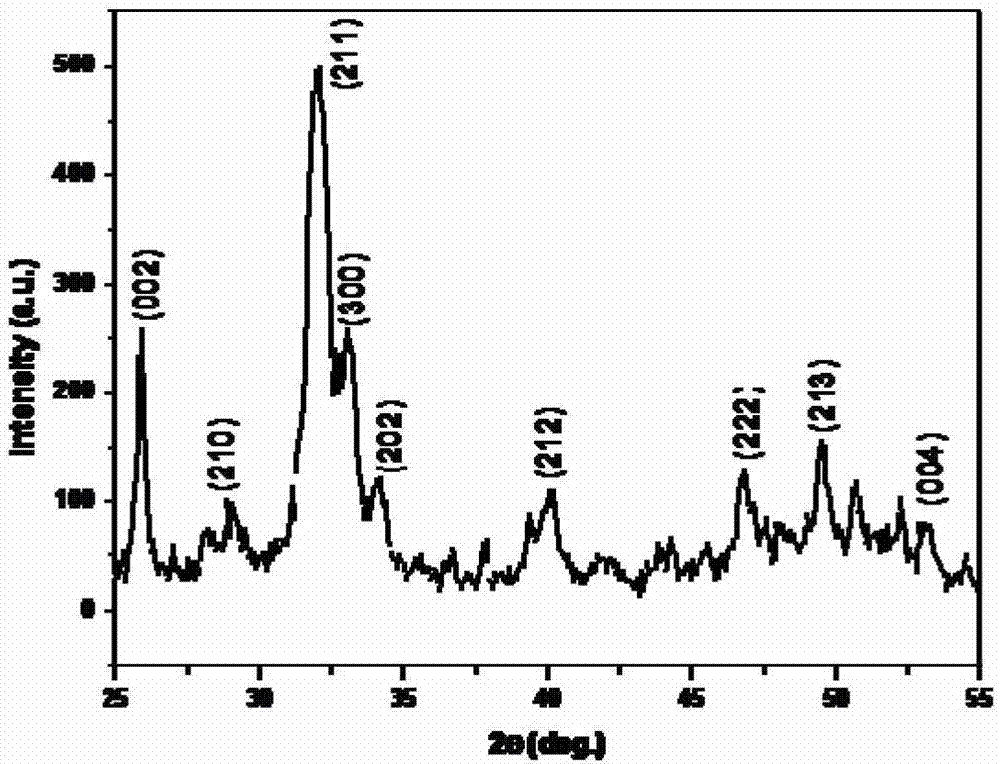

A hydroxyapatite and flower-like technology, applied in the field of porous hydroxyapatite flower-like microspheres and its preparation, to achieve the effects of shortened reaction time, strong diffraction peaks, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A kind of preparation method of porous hydroxyapatite flower-like microsphere of the present invention, comprises the following steps:

[0026] First, add CaO to 80°C distilled water to digest it into Ca(OH) with a concentration of 1% to 10%. 2 For slurry, the digestion time is more than 10h to ensure that the CaO is completely digested; at room temperature, the Ca(OH) 2 Slurry into CO 2 / N 2 Mixed gas, CO 2 and N 2 The molar ratio is 0.1-0.5, the speed is 1L / min, and the reaction stops when the pH value of the reaction system reaches 7.

[0027] Then add Al(OH) 3 The molar ratio of calcium to aluminum is 5:1~50:1; phosphate solution is added under heating (usually 60°C) and stirring, and NaOH solution is added during the reaction to keep the pH of the reaction system at 10.0. After 2~4 hours of reaction, the The white precipitate is separated from the mother liquor, and the precipitate is centrifuged and washed with distilled water until the pH value of the solut...

Embodiment 1

[0032] Add 0.56g CaO to 80°C distilled water to digest it into Ca(OH) with a mass concentration of 1%. 2 For slurry, the digestion time is 11 hours to ensure complete digestion of CaO. At room temperature, and with mechanical stirring, the slurry was bubbled with CO 2 / N 2 Mixed gas (CO 2 and N2 The molar ratio is 0.2), the speed is 1L / min, and the pH value of the reaction system reaches 7 to stop the reaction. Then add Al(OH) 3 , the molar ratio of calcium to aluminum is 20:1. Under electric stirring at 60°C in a water bath, 20ml of the prepared 0.3mol / L sodium phosphate solution was added dropwise. During the reaction, NaOH solution was added to keep the pH of the reaction system at 10.0, and the reaction was carried out for 2h. Centrifuge, wash the precipitate until the pH value of the solution reaches 7, centrifuge, and dry at 80°C for 24h to obtain a powder product. The stirring condition in this embodiment is 200 rpm.

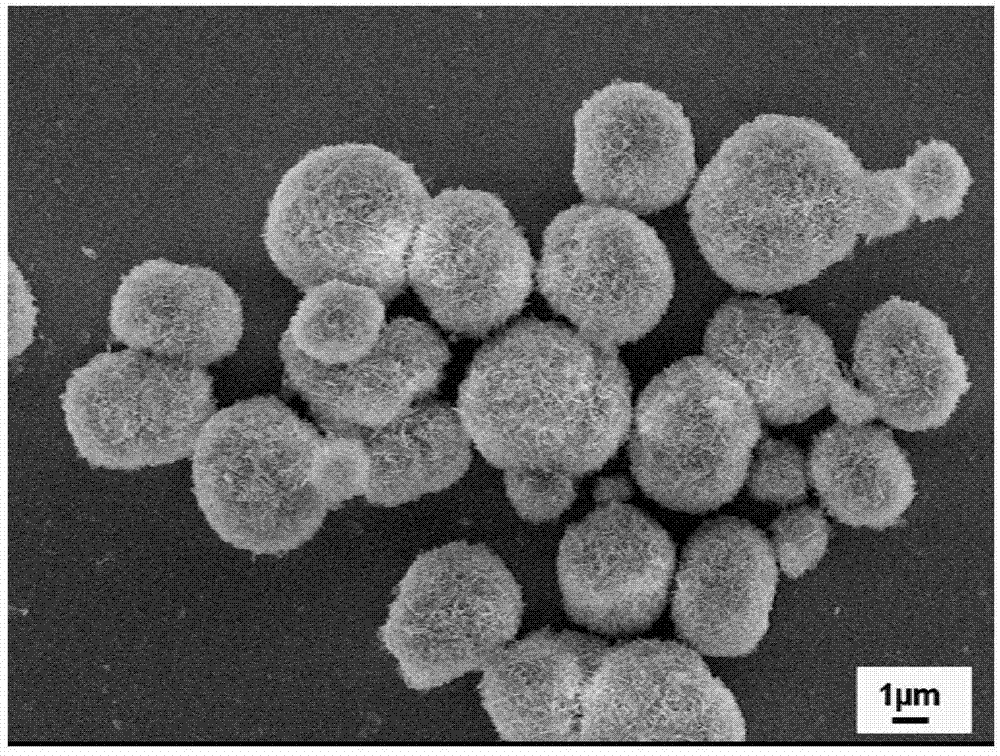

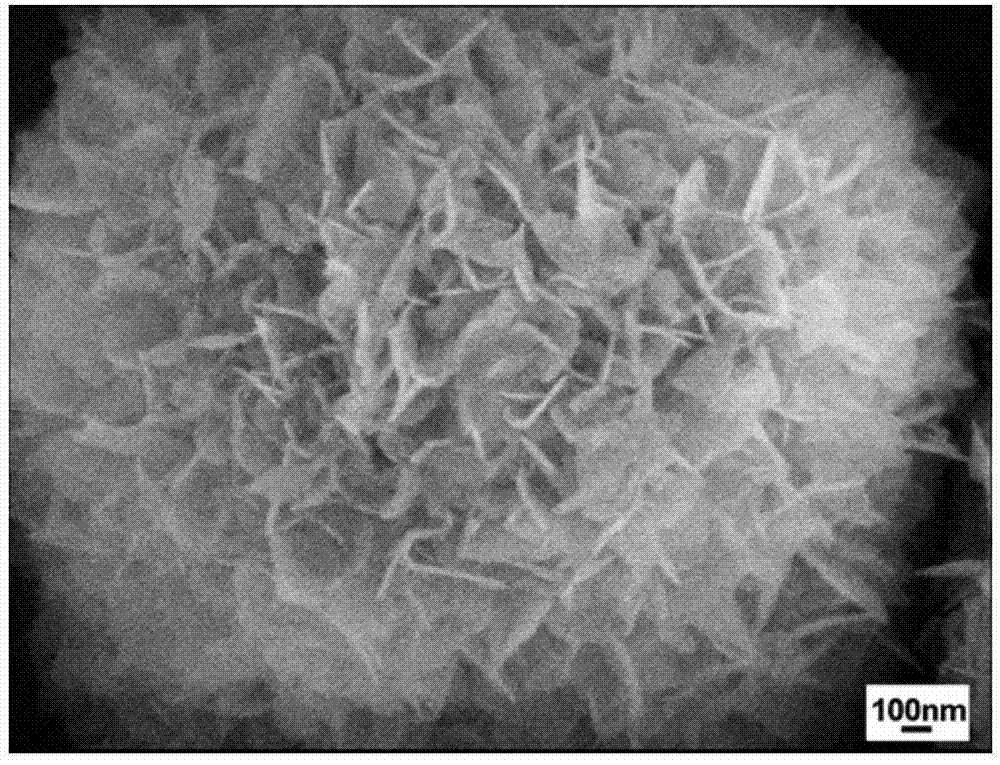

[0033] Field emission scanning electron micr...

Embodiment 2

[0035] Add 0.56g CaO to 80°C distilled water to digest it into Ca(OH) with a mass concentration of 3%. 2 For slurry, the digestion time is more than 12 hours to ensure complete digestion of CaO. At room temperature, and with mechanical stirring, the slurry was bubbled with CO 2 / N 2 Mixed gas (CO 2 and N 2 The molar ratio is 0.3), the speed is 1L / min, and the pH value of the reaction system reaches 7 to stop the reaction. Then add Al(OH) 3 , the molar ratio of calcium to aluminum is 10:1. Electric stirring under 60 ° C water bath, the prepared 0.3mol / L Na 2 HPO 4 Add 20ml of the solution dropwise, add NaOH solution during the reaction to keep the pH of the reaction system at 10.0, and react for 3h. Centrifuge, wash the precipitate until the pH value of the solution reaches 7, centrifuge, and dry at 80°C for 24h to obtain a powder product. The stirring condition in this embodiment is 300 rpm.

[0036] Figure 4 It is a scanning electron micrograph of the porous hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com